Mold Design: Making Cool Things with Plastic

Have you ever wondered how thousands of identical plastic toys or bottles are made? It all starts with a clever plan called a mold.

Imagine you have a great idea for a new plastic toy or a cool water bottle. But there is a big problem: you need to make thousands of them, and they all must look exactly the same! If you try to make them by hand, it will take forever and look messy. This is where a smart Plastic injection molding design helps you solve the puzzle. It acts like a master blueprint that lets a machine pop out perfect parts every few seconds.

What is a magic Plastic injection molding design?

Think about this:

When you bake cookies at home, you use a metal shape to press into the dough so every cookie is a perfect star.

- •It gives plastic its final shape.

- •It holds the shape until it’s hard.

- •It makes every piece the same size.

| Feature | How it Works | Why it Matters |

|---|---|---|

| Hollow Shape | Creates the part’s look | Matches your idea |

| Metal Walls | Stays strong under heat | Lasts a long time |

| Cooling Tunnels | Chills plastic fast | Saves a lot of time |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

A mold is a metal tool that acts like a cookie cutter to turn hot liquid plastic into solid, perfect shapes.

How does Plastic injection molding design help us build?

A good Plastic injection molding design makes sure your parts are strong and don’t break when you drop them. It is the first step to making a high-quality product that people will love.

Does it work like LEGO blocks?

You won’t believe it:

Your favorite bricks snap together because the mold had very straight edges and perfect corners.

- •Parts fit without using glue.

- •Plastic is the same thickness.

- •Bricks don’t bend or warp.

| Design Goal | How to Do It | Result |

|---|---|---|

| Strength | Add tiny ribs inside | Won’t break easily |

| Speed | Add cooling holes | Makes more parts |

| Beauty | Polish the metal | Shiny and new look |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

Good design ensures your parts are strong, fit together perfectly, and can be made very quickly to save time.

Why are custom molds better for your ideas?

When you use a Plastic injection molding design made just for you, your product will be unique and special. You don’t have to use the same shapes that everyone else is using.

Can you make a unique shape?

Imagine this:

You want a bottle shaped like a rocket ship. A custom mold can do that because we carve the shape into steel.

- •No one else has your design.

- •It makes your brand stand out.

- •The shape is exactly as dreamed.

| Benefit | Custom Mold | Standard Shape |

|---|---|---|

| Uniqueness | 100% Yours | Looks like others |

| Logo | Built-in | Needs a sticker |

| Fit | Perfect for your part | Might be loose |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

Custom molds allow you to create unique shapes, colors, and logos that make your product stand out from the crowd.

Can Plastic injection molding design save you money?

A smart Plastic injection molding design helps you use less plastic and make parts faster. When you don’t waste material, you keep more money in your pocket.

How do we use less plastic?

Here is the secret:

Engineers make walls thinner but add tiny ‘ribs’ for strength so we use much less gooey plastic.

- •Less material costs less.

- •Thinner parts cool fast.

- •Machine runs more cycles.

| Saving Method | Action | Money Saved |

|---|---|---|

| Material | Thin walls | High |

| Time | Better cooling | Very High |

| Repair | Strong steel | Medium |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

Smart design choices like thin walls and fast cooling reduce costs and let you make more products for less money.

How do we make custom molds from metal?

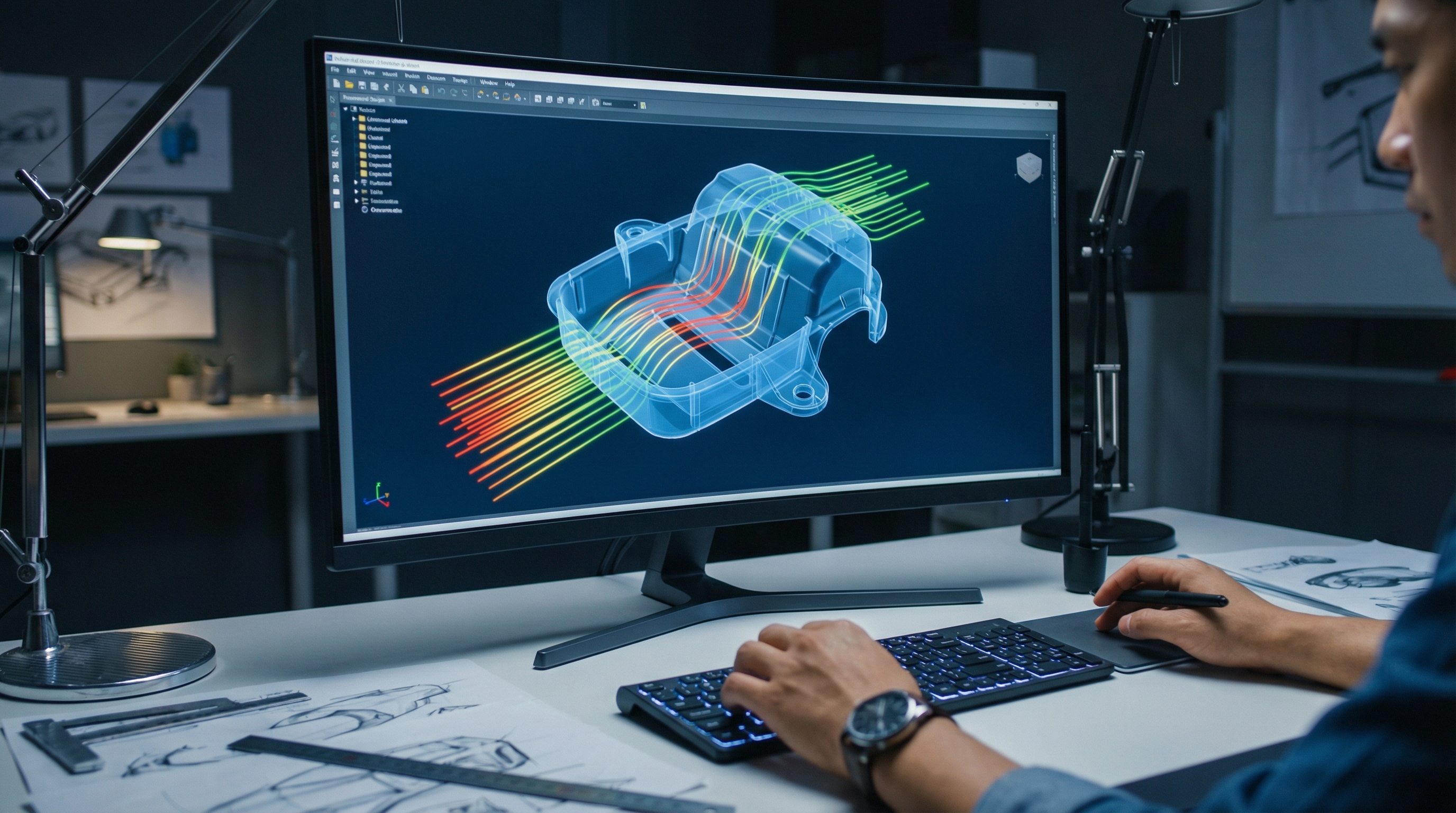

Creating a Plastic injection molding design starts on a computer and ends with heavy steel. It is a journey from a digital dream to a real tool.

How do computers help us?

Check this out:

First, we draw your idea in a 3D program that looks like a video game to fix mistakes on the screen.

- •Test plastic flow.

- •Fix digital mistakes.

- •Guide the carving robot.

| Step | Tool Used | Purpose |

|---|---|---|

| Drawing | 3D Software | Plan the shape |

| Carving | CNC Robot | Cut the steel |

| Polishing | Hand Tools | Make it smooth |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

We use computers and robots to carve strong steel into perfect shapes that last for a very long time.

Is Plastic injection molding design used for cars?

Many parts of a car are made using a Plastic injection molding design. From the dashboard to light covers, plastic makes cars lighter.

Why are car parts plastic?

The best part is:

Plastic is much lighter than metal, which helps the car use less gas and it won’t ever rust.

- •Lighter cars go faster.

- •Curvy shapes look great.

- •Safe if there is an accident.

| Car Part | Why Plastic? | Mold Type |

|---|---|---|

| Dashboard | Style and safety | Large Mold |

| Buttons | Detail and feel | Precision Mold |

| Light Covers | Clarity and strength | Polished Mold |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

Plastic molds are essential for cars because they create parts that are light, safe, and can be formed into complex shapes.

Can we use Plastic injection molding design for tools?

Why are tool handles soft?

Wait until you see:

Some molds use two plastics at once to put a hard core for strength and soft rubber on top.

- •Comfortable to use.

- •Stops tool from slipping.

- •Looks cool with two colors.

| Tool Part | Material | Job |

|---|---|---|

| Outer Shell | Hard Plastic | Protection |

| Handle Grip | Soft Rubber | Comfort |

| Internal Gear | Tough Nylon | Movement |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

Molds create the tough shells and comfortable grips that make our everyday tools safe and easy to use.

How does HST Technology help with your ideas?

At HST Technology, we take your drawings and turn them into real plastic parts. We are like a team of helpers who know the magic boxes.

Do they listen to your plans?

Trust me on this:

When you message us, our engineers look at your idea and give advice within 24 hours.

- •Help with hard shapes.

- •Suggest ways to save.

- •Answer questions quickly.

| HST Service | What We Do | Benefit for You |

|---|---|---|

| Expert Review | Check your drawing | No mistakes later |

| Fast Response | Reply in 1 day | Project moves fast |

| Manufacturing | Build the mold | High quality parts |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

HST Technology provides the expertise and the factory power to turn your sketches into high-quality plastic products.

Why is fast response important in custom molds?

Does waiting cost money?

Think of it like this:

If a factory takes too long, you are losing days when you could be selling your products.

- •Start earning sooner.

- •Fast answers move projects.

- •No missed deadlines.

| Milestone | Typical Time | Our Goal |

|---|---|---|

| First Quote | 3-4 Days | 24 Hours |

| Design Fixes | 1 Week | 2-3 Days |

| Weekly Update | Monthly | Every Week |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

Fast communication and quick work help you avoid mistakes and get your product into the hands of customers much sooner.

How do we check the quality of custom molds?

What is a measuring robot?

Guess what?

We use a CMM machine that has a tiny finger to touch the mold and make sure the size is perfect.

- •See tiny mistakes.

- •Measure size of a hair.

- •Ensures parts fit.

| Quality Check | What is it? | Why do it? |

|---|---|---|

| CMM Scan | Robot measuring | Perfect size |

| T1 Sample | First test part | Customer approval |

| Batch Check | Constant looking | No bad parts |

This simple chart helps explain how our design choices make your project better.

Key Takeaway:

Rigorous testing and high-tech measuring robots ensure that every part we make is high-quality and perfect for your needs.

Frequently Asked Questions

Can I make a mold for any shape?

Yes, most shapes work. Some very complex ones might need moving parts, but we can help you fix your drawing.

What is the best metal for a mold?

Steel is usually the best. It is very strong and can make millions of parts without wearing out.

How do I know if my design is too thin?

Simple check: if it’s as thin as paper, it might be too thin. We will tell you if you need to make it thicker.

How long does it take to make a mold?

It takes about 4 to 6 weeks. We carve the steel and test the parts to make sure they are perfect.

Is plastic molding safe for the earth?

Yes, many plastics can be recycled. We always try to use material wisely to avoid any waste.