Have you ever wondered how someone can make millions of Lego bricks or plastic water bottles that all look exactly the same? It is very hard to make things by hand one by one. If you tried to carve a thousand toy cars out of wood, they would all be slightly different, and it would take you many years to finish!

If a company makes parts that don’t fit together, they waste a lot of money. It is frustrating when a toy breaks or a lid does not fit on a bottle. This happens when the tools used to make them are not fast or accurate enough.

There is a better way to build things. It is called plastic injection molding. This is a special way to make thousands of perfect plastic parts very quickly. In this guide, we will show you exactly how it works and why it is so cool.

What is Plastic Injection Molding?

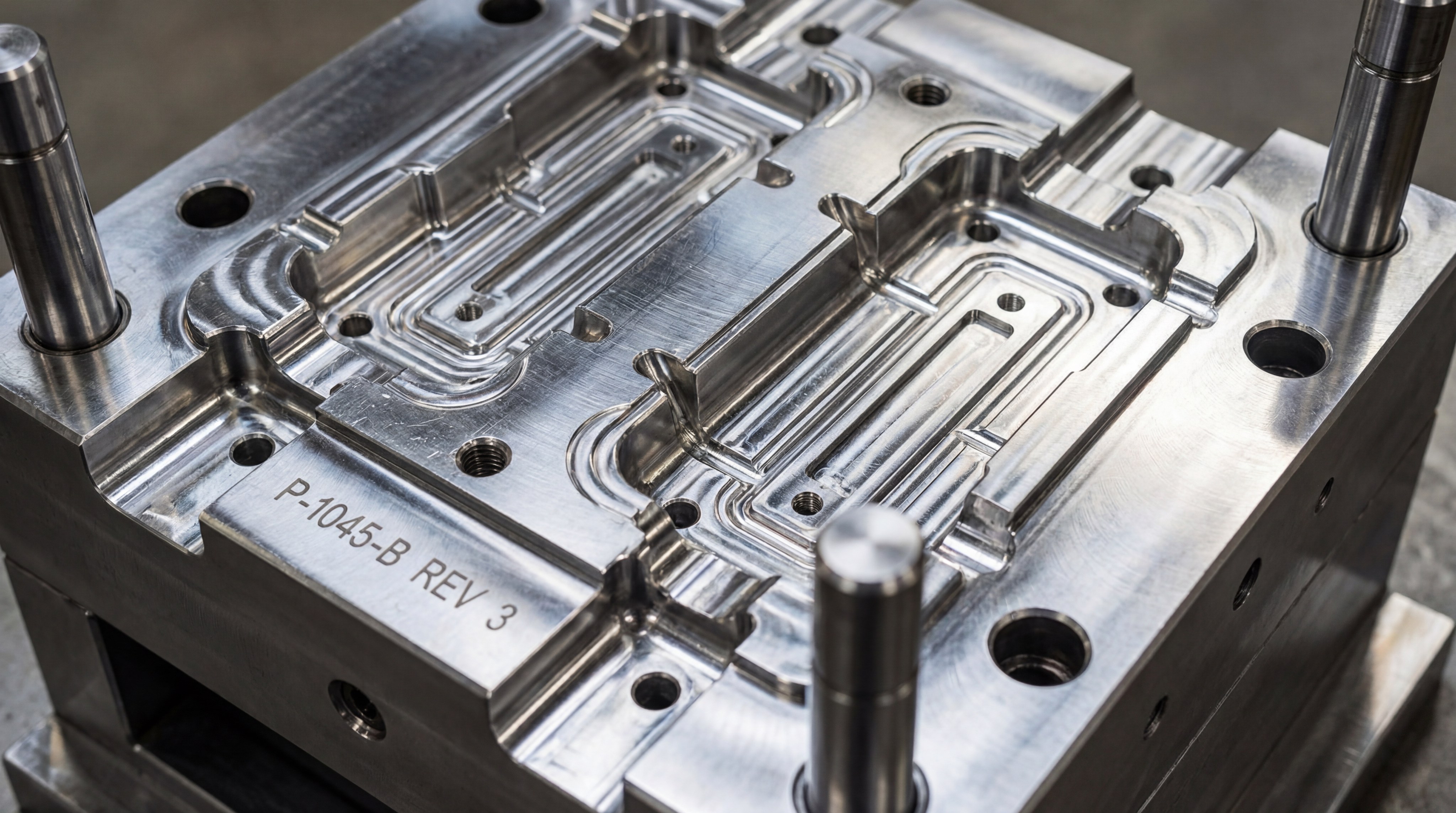

Plastic injection molding is a way to make parts by melting plastic and squishing it into a shape. To do this, we need two main things: The Machine and The Mold.

The mold is like a waffle iron or a Jello tray. Whatever shape is inside the mold is exactly what the plastic will look like when it comes out!

How Does it Work? (Step-by-Step)

Making a plastic part is like a recipe. First, we start with tiny pieces of plastic that look like colorful grains of sugar. The machine gets very hot and melts them into a thick liquid, like honey. Next, the machine pushes this hot plastic ‘goo’ into the metal mold very fast.

The mold is kept cool. As soon as the hot plastic touches the cold metal, it turns back into hard plastic. Finally, the mold opens up, and the finished part falls out. Now, the machine is ready to do it all over again!

What We Can Build

At HST-Tech, we can make almost anything out of plastic. We make parts for cars, tools for doctors, and even things you use in your house. Because our machines are so smart, we can make very tiny parts or very big ones.

Quality Control at HST-Tech

We want to make sure every single piece of plastic is perfect. We do not like mistakes! We use special computers to watch the machines. If a part is even a tiny bit wrong, the computer tells us right away. We check the size, the color, and the strength of the parts.

Building the Future

Plastic injection molding is the best way to make lots of high-quality items quickly. From the toys in your room to the parts in a car, this process helps build the world around us. It saves time, saves money, and makes sure everything works just right.

Common Questions

What materials are used?

Most injection molding uses special plastic beads called resins. These beads can be hard, soft, or even stretchy.

How long does it take to make a mold?

Creating the metal mold takes the most time. It can take a few weeks, but once it is done, we can make thousands of parts every day.

Is it expensive?

The first part is expensive because the mold costs money. But after that, every part is very cheap to make!

Can you recycle the plastic?

Yes! Many plastics we use can be melted down and used again. This helps keep the Earth clean.