The big problem is that making things by hand takes forever and is very hard to do perfectly every time. This is a huge headache for companies that need to make millions of parts that must fit together perfectly. Plastic injection molding is the hero of this story because it uses a giant machine and a metal mold to pop out perfect plastic parts in seconds.

Want to know a secret? Expert factories like HST Technology Limited have spent over 10 years perfecting this “magic” to help people in Europe and all over the world get the high-quality products they need.

What exactly is Plastic injection molding?

Plastic injection molding is a manufacturing process that works like a high-tech version of a kitchen cookie cutter or a jelly mold. Instead of dough, we use tiny plastic beads that are melted down and squeezed into a shape.

Is it like using Play-Doh?

Think of it like a Play-Doh factory set where you push the dough through a star-shaped hole. In the real factory, we use a steel mold that has the exact shape of the part we want to make.

- The machine uses tons of pressure to make sure the plastic fills every tiny corner.

- Once the plastic gets cold, it turns back into a hard solid.

- The mold opens up, and the finished part falls out, ready to be used.

Why do we call it “injection”?

The word injection is used because the melted plastic is “squirted” into the mold through a small hole, just like a doctor might use a needle. Here is the deal: this happens so fast that you can barely see it!

- The plastic moves through a heated barrel.

- A giant screw pushes the liquid plastic forward.

- It enters the mold at a very high speed to keep it from cooling too early.

Key Takeaway: This process is the fastest way to turn liquid plastic into a solid, useful shape that is exactly the same every single time.

| Feature | Description | |

|---|---|---|

| Core Concept | Filling a shape with liquid material | |

| Primary Material | Thermoplastic resins | |

| Speed | Very fast (seconds per part) | |

| Precision | Extremely high |

The high precision of this method ensures that even tiny parts for electronics fit together without any gaps.

How does the Plastic injection molding process actually work?

The plastic injection molding process follows a specific cycle that involves heating, squeezing, and cooling to create a finished part. It is a continuous loop that can run 24 hours a day to make thousands of items.

What happens in the melting stage?

Before anything else, the plastic starts as small, hard pellets that look like colorful sprinkles. These pellets are poured into a hopper and fall into a heated tube where they melt into a thick goo.

- Heaters around the tube get very hot to melt the plastic.

- A rotating screw mixes the plastic to keep the temperature even.

- The melted plastic waits at the front of the screw for the next step.

How is the plastic pushed into the mold?

Once the plastic is melted, the screw acts like a giant plunger to force the liquid into the metal mold. It gets even better because the machine can control exactly how much pressure is used.

- The mold is held shut by a very strong clamp.

- The liquid plastic fills up every empty space inside the mold.

- The machine keeps pushing for a moment to “pack” the plastic in tightly.

Key Takeaway: Understanding the cycle steps helps engineers ensure that every part comes out strong and without any bubbles or holes.

| Cycle Step | What Happens | |

|---|---|---|

| Clamping | The mold is locked tight | |

| Injection | Melted plastic fills the mold | |

| Cooling | The plastic hardens into a solid | |

| Ejection | The finished part is pushed out |

This repeatable cycle is why factories can produce millions of parts with zero differences between the first and last one.

Which materials are best for Plastic injection molding?

Plastic injection molding can use many different types of plastic, each with its own special “superpowers” like being extra strong or very flexible. Choosing the right material is like choosing the right ingredients for a cake.

What are the most common plastics?

Most of the things you touch every day, like milk jugs or LEGO bricks, are made from specific plastics called “thermoplastics.” These are special because they can be melted and cooled over and over again.

- ABS is very tough and used for toys like LEGOs.

- Polypropylene is flexible and great for food containers.

- Polycarbonate is clear and strong, like a see-through shield.

Can we add special things to the plastic?

Believe it or not, we can mix in other materials to make the plastic even better. We can add colors, glass fibers for strength, or even materials that stop the plastic from catching fire.

- Color pellets make the final product any color you want.

- UV stabilizers keep the plastic from fading in the sun.

- Lubricants help the part slide out of the mold more easily.

Key Takeaway: The ability to choose from thousands of plastic recipes means you can make a part that is perfect for its specific job.

| Material Type | Common Use | Main Benefit | |

|---|---|---|---|

| ABS | Toy Bricks | Very impact resistant | |

| Nylon | Gears and Bolts | Strong and slippery | |

| Polyethylene | Plastic Bottles | Cheap and safe for food |

Selecting the correct material early in the design phase prevents product failure and saves money during production.

Why is Plastic injection molding the best choice for mass production?

Plastic injection molding is the champion of mass production because it allows us to make millions of parts very cheaply once the mold is built. While the first part is expensive, the millionth part costs almost nothing.

How does it save time?

In a modern factory, a single machine can pop out a new part every 15 to 30 seconds. If you have a mold with many “cavities” (holes), you can make 10 or 20 parts at the same time!

- Machines run automatically without needing a person to hold them.

- The cooling process happens very quickly thanks to water channels inside the mold.

- There is very little waste because extra plastic can be melted and used again.

Is the quality always the same?

Want to know a secret? Because the mold is made of hard steel, the shape never changes, which means every part is a twin of the one before it.

- Computers monitor the pressure and heat for every single shot.

- The machine knows exactly when something goes wrong and stops itself.

- This consistency is why car companies trust this process for safety parts.

Key Takeaway: High-volume production becomes much more affordable and reliable when you use this technology for your products.

| Production Factor | Benefit | |

|---|---|---|

| Labor Cost | Low (automated) | |

| Material Waste | Low (recyclable) | |

| Output Speed | High (millions per year) |

The initial investment in a steel mold is quickly recovered by the low cost per part in high-volume runs.

How do you design parts for Plastic injection molding?

Plastic injection molding requires a special kind of design where you have to think about how the plastic will flow and how the part will pop out. If you design it wrong, the part might get stuck or have weird bumps.

Why do parts need “draft angles”?

Imagine trying to pull a square ice cube out of a tray; it’s hard! If the sides are slightly tilted like a cupcake wrapper, the part slides out much easier.

- Draft angles prevent the plastic from scraping the mold.

- They make the part pop out faster, which saves money.

- Even a tiny 1-degree tilt can make a huge difference.

What is “uniform wall thickness”?

Here is the deal: plastic shrinks when it gets cold. If one part of your toy is very thick and another is very thin, it will bend and warp like a piece of dry wood.

- Engineers try to keep the “skin” of the part the same thickness everywhere.

- Ribs are added to make thin walls stronger without adding too much plastic.

- This keeps the part flat and prevents “sink marks” (little dents).

Key Takeaway: Good design makes the manufacturing process smoother and ensures your parts look beautiful and professional.

| Design Rule | Reason | |

|---|---|---|

| Add Draft | Easier ejection | |

| Thin Walls | Faster cooling | |

| Round Corners | Better plastic flow |

Following these simple design rules can reduce your manufacturing costs by up to 30% and prevent quality issues.

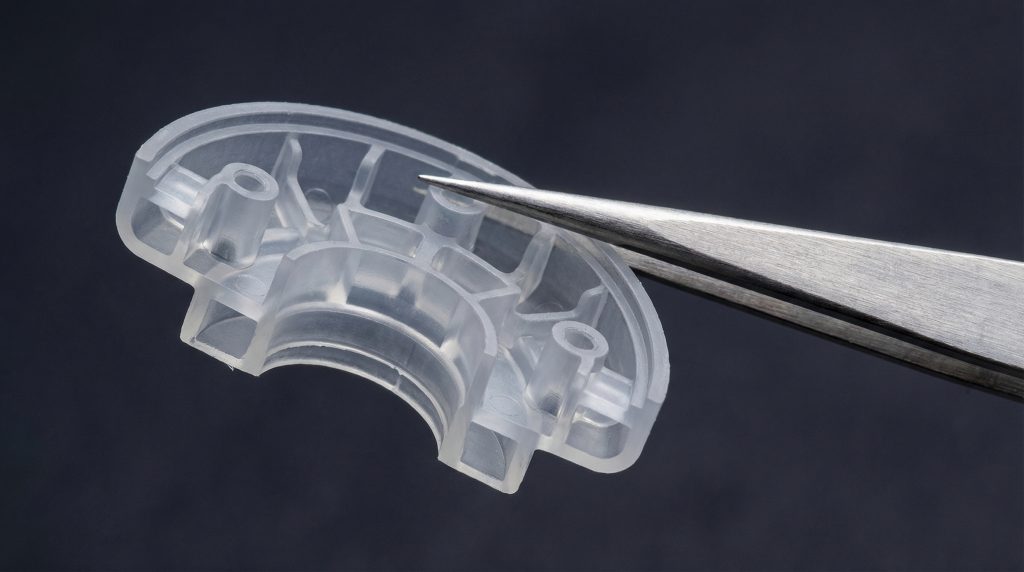

Can Plastic injection molding create complex shapes?

Plastic injection molding is surprisingly good at making very complicated items, like the inside of a car door or a medical device. We can use “side-actions” and “sliders” to make holes and shapes that go in different directions.

What are “moving parts” in a mold?

Some molds are like Transformers; they have pieces that move in and out while the plastic is cooling. This allows us to make things with threads (like a screw) or holes on the side.

- Slides move out of the way before the mold opens.

- Lifters help release parts with “under cuts” (hidden lips).

- Unscrewing molds can create perfect threads for bottle caps.

Can you mold two materials at once?

It gets even better! Some machines can inject two different colors or even a soft rubber over a hard plastic, which is called “overmolding.”

- This is how your toothbrush gets its soft, grippy handle.

- It creates a permanent bond between the two materials.

- It saves time because you don’t have to glue parts together later.

Key Takeaway: Don’t be afraid to design complex parts; modern mold-making technology can handle almost any shape you can imagine.

| Complex Feature | Tooling Solution | |

|---|---|---|

| Side Holes | Cam Sliders | |

| Internal Threads | Rotating Cores | |

| Soft Grips | Overmolding |

Complex molds take longer to build but allow for single-piece designs that replace many smaller, assembled parts.

What determines the cost of Plastic injection molding?

Plastic injection molding cost is divided into two main parts: the price of making the metal mold and the price of each individual plastic part. It is a bit like buying a printer; the machine is expensive, but the paper is cheap.

Why are the molds so expensive?

Molds are made by master craftsmen out of very hard steel using high-precision robots. They have to withstand thousands of pounds of pressure and stay perfect for many years.

- Complex shapes require more time to carve and polish.

- Harder steel lasts longer but is more difficult to work with.

- Molds for large items, like a trash can, are huge and heavy.

How can you lower the price per part?

Want to know a secret? The more parts you make, the cheaper each one becomes because the cost of the mold is shared by more items.

- Buying plastic in bulk saves a lot of money.

- Fast cycle times mean the machine can do more work in an hour.

- Using “multi-cavity” molds produces many parts for every “click” of the machine.

Key Takeaway: Investing in a high-quality mold from a factory like HST is the best way to ensure long-term savings and reliability.

| Cost Driver | Impact on Price | |

|---|---|---|

| Part Complexity | Increases mold cost | |

| Material Choice | Varies part cost | |

| Production Volume | Decreases part cost |

Understanding these cost drivers allows businesses to plan their budgets effectively for successful product launches.

How does Plastic injection molding ensure high quality?

Plastic injection molding is famous for its high quality because everything is controlled by computers and tested by expert engineers. At factories like HST, quality is the most important rule.

What is a “First Article Inspection”?

Before the machine starts making thousands of parts, the engineers take the very first few and measure them with super-accurate tools. This makes sure the mold is perfect before the big run begins.

- Measurement tools can see things smaller than a human hair.

- Every dimension is checked against the original 3D drawing.

- The first parts are sent to the customer for their “thumbs up.”

How do machines catch mistakes?

Modern molding machines have “eyes” and “brains” that watch every single shot. If the plastic is too cold or the pressure is too low, the machine will sound an alarm.

- Sensors inside the mold track the plastic as it flows.

- Bad parts are automatically separated from the good ones.

- Digital logs keep a record of every single part made.

Key Takeaway: Strict quality control systems mean you can trust that every part you receive will work perfectly in your product.

| Quality Check | Tool Used | |

|---|---|---|

| Dimensions | CMM Robot | |

| Color Match | Spectrophotometer | |

| Strength | Stress Test Machine |

Consistent quality control reduces waste and protects your brand’s reputation in the competitive marketplace.

What are the different types of Plastic injection molding machines?

Plastic injection molding machines come in many sizes, from small ones that fit on a desk to giant ones the size of a house. The type of machine used depends on how big the part is and how much pressure is needed.

What is a “Tonnage” rating?

The strength of a machine is measured in “tons.” This tells you how hard the machine can squeeze the mold to keep it shut while the plastic is injected.

- Small parts like buttons use 20-50 ton machines.

- Medium parts like lunchboxes use 100-300 ton machines.

- Huge parts like car bumpers need machines with 2,000 tons of force!

Are there different ways to power the machine?

Some machines use oil (hydraulic) and some use electricity. Electric machines are becoming very popular because they are cleaner and use less energy.

- Hydraulic machines are very strong and good for big parts.

- Electric machines are very quiet and precise for medical parts.

- Hybrid machines use a little bit of both for the best results.

Key Takeaway: Having the right machine for the job ensures that your parts are made efficiently and with the highest level of detail.

| Machine Type | Best Used For | Power Source | |

|---|---|---|---|

| Small Electric | Medical/Precision | Electricity | |

| Large Hydraulic | Automotive/Large | Oil Pressure | |

| Vertical Machine | Insert Molding | Hydraulic/Electric |

Choosing a factory with a diverse range of machines ensures they can handle your project as it grows in size or complexity.

Why should you choose HST for Plastic injection molding?

Plastic injection molding is a complex business, and having a partner with 10+ years of experience makes all the difference. HST Technology Limited is a direct factory that understands exactly what European customers need.

What makes a “Direct Factory” better?

When you work with a direct factory like HST, there are no “middlemen” to slow things down or make it more expensive. You talk directly to the engineers who are building your mold.

- Direct communication means fewer mistakes and faster answers.

- You get the best price because you are buying straight from the source.

- The factory takes full responsibility for the quality of your parts.

Do they understand European standards?

HST has been exporting to countries like Germany and the UK for a long time. They know that European buyers want perfect parts, clear documentation, and on-time delivery.

- They provide detailed reports and certifications for all materials.

- Their engineers speak the language of international manufacturing.

- They focus on long-term partnerships rather than just one-time sales.

Key Takeaway: Choosing an experienced, direct factory partner is the smartest way to turn your product ideas into reality without any stress.

| Why HST? | Customer Benefit | |

|---|---|---|

| 10+ Years Exp | Reliability & Knowledge | |

| Direct Factory | Lower Costs | |

| EU Focused | High Quality Standards |

Partnering with an export-ready factory ensures that your products meet all safety and quality regulations for your local market.

Conclusion

Plastic injection molding is the amazing technology that brings our favorite things to life. By melting plastic and squishing it into perfect molds, we can create everything from tiny gears to giant car parts. This process solved the problem of making many identical items quickly and cheaply, making it the backbone of modern life.

If you are ready to start your own project or have more questions about how to make your plastic parts, we are here to help! Our team at HST Technology Limited has the tools and the heart to make your vision come true. Please contact us today to get a free quote and see how we can build something great together. We don’t just make molds; we build the future of manufacturing!

FAQ: Common Questions About Plastic Injection Molding

Can I use injection molding for just a few parts?Generally, it is not the best choice for small numbers because the mold is expensive. It is usually better to use this method when you need at least 1,000 pieces to make the cost of the mold worth it.

What’s the best material for a toy that needs to be very strong?The most common choice is ABS plastic because it is very tough and doesn’t break easily when dropped. It is the same material used to make the famous LEGO bricks that last for generations.

How do I know if my design is ready for molding?The best way is to show it to an expert engineer who can do a “DFM” (Design for Manufacturing) review. They will look for things like draft angles and wall thickness to make sure the part can be made perfectly.

Can I change the color of my parts later?Yes, you can change the color easily by simply swapping the color pellets in the machine. You can even make some parts blue and some parts red using the exact same mold!

How long does it take to make a new mold?It usually takes between 4 to 8 weeks depending on how complex the shape is. While this seems like a long time, remember that once the mold is done, you can make thousands of parts every single day!