Automotive Injection Molding Explained: How It Works, Typical Applications, and Advantages

Do you worry about making car parts fast enough? Many people struggle with making strong parts that do not cost too much money. If you use slow tools, you might lose your place in the busy market. Here is the deal. We have a great way for you to make perfect car parts every time. automotive injection molding is the best solution for your big projects. Our team at HST Tech knows how to build tools that work hard for your business.

# 1. What is automotive injection molding?

Automotive injection molding is a way to make plastic car parts by pushing melted plastic into a metal shape. This process helps workers create many items that look exactly the same very quickly. You might be wondering how it helps your car. This method makes parts like bumpers, dashboards, and door handles. Big machines melt plastic beads and then squeeze them into a cold mold.

How it started ● People used this for small buttons first. ● Now it makes big parts for fast cars. ● Technology changed a lot in 75 years.

Wait, there is more. Because this process is so fast, it saves you a lot of time and money.

Key Takeaway: This method is a fast way to make many strong car parts that look the same.

Summary of Basics

| Part Type | Speed | Material |

|---|---|---|

| Interior | High | Plastic |

| Exterior | High | Strong Resin |

| Engine | Medium | Heat-proof |

Using these machines helps you finish big jobs without any stress.

# 2. How does the automotive injection molding process work?

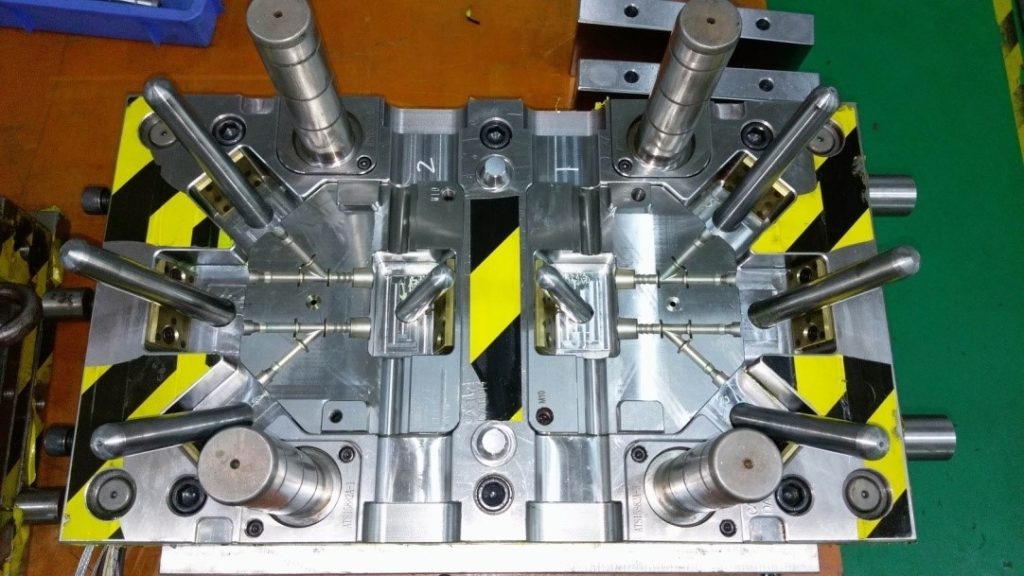

The automotive injection molding process works by melting plastic and injecting it into a tool under high pressure. You start with tiny plastic pellets in a big hopper. Ready for the good part? A large screw turns and heats the plastic until it becomes like thick syrup. Then, the machine pushes this hot liquid into a steel mold. Once the plastic cools down, the mold opens up and your new car part falls out.

Steps in the machine ● Filling the hopper with beads. ● Melting the plastic with heat. ● Pushing the liquid into the mold.

But here is the kicker. The cooling stage takes the most time because plastic stays warm for a while.

Key Takeaway: Machines melt plastic and squeeze it into molds to build parts quickly.

Process Stages

| Step | Action | Time Needed |

|---|---|---|

| Melting | Heat beads | Short |

| Injecting | Squeeze in | Very Short |

| Cooling | Wait | Longest |

Knowing these steps helps you plan your factory work better.

# 3. How does automotive injection molding help vehicles become lighter?

Automotive injection molding helps cars weigh less by using light plastic instead of heavy metal. Lighter cars use less gas and move faster on the road. Think about it. Every pound you save makes the car better for the driver. Engineers use special plastics that are strong but weigh very little. This is why many parts under the hood are now made of plastic instead of iron.

Why weight matters ● Cars use less fuel when light. ● Electric cars can go farther. ● It is easier to stop a light car.

This is where it gets interesting. Strong plastics can now do the same job as old metal parts.

Key Takeaway: Plastic parts made this way help cars save gas by being very light.

Weight Comparison

| Material | Weight | Strength |

|---|---|---|

| Steel | Heavy | High |

| Aluminum | Medium | High |

| Plastic | Light | Good |

Switching to plastic is a smart move for any car maker today.

# 4. Why does automotive injection molding reduce car noise?

This process reduces car noise by creating parts that fit together perfectly and block sounds. You want your car cabin to be quiet so you can talk to friends. The best part is that plastic parts can have special foam inside them. These parts stop the engine from making loud shaking sounds. Molding creates shapes that trap sound waves and keep them away from your ears.

Ways to block noise ● Using soft plastic inserts. ● Making parts that fit tight. ● Adding ribs to stop shaking.

Believe it or not, a quiet car feels much more expensive than a noisy one.

Key Takeaway: Good plastic parts keep the car quiet by blocking engine and wind noise.

Noise Control

| Part | Goal | Effect |

|---|---|---|

| Door Panel | Block wind | Quiet Cabin |

| Engine Cover | Stop hum | Calm Drive |

| Floor Mat | Stop road noise | Soft Ride |

Quiet parts make every trip in the car more fun for everyone.

# 5. Is automotive injection molding good for strong car parts?

Yes, this method is great for making strong parts that last a very long time. Car parts must survive hot sun and cold snow without breaking. What is the real story? We use engineering plastics that are as tough as some metals. These parts do not rust like steel does. When you mold a part, you can make it thicker in places where it needs to be extra strong.

Tests for strength ● Dropping heavy things on it. ● Heating it up in an oven. ● Bending it many times.

It gets even better. These parts keep their shape even after many years of hard use.

Key Takeaway: Plastic car parts are very tough and do not rust or break easily.

Durability Facts

| Test | Result | Benefit |

|---|---|---|

| Heat | No melting | Lasts in sun |

| Impact | No cracking | Safe for kids |

| Rust | None | Clean car |

Strong parts keep your car safe and looking new for a long time.

# 6. Can we recycle parts made with automotive injection molding?

You can recycle many car parts made this way by melting them down again. This helps our planet by keeping old plastic out of the trash. Do you want to know a secret? Many new car parts are made from old bumpers and bottles. Factories can grind up old parts into small beads. Then, they put those beads back into the machine to make brand new items for your car.

Ways to recycle ● Grinding old parts into bits. ● Mixing old and new plastic. ● Using green energy for heat.

Now check this out. Recycling also saves money for the company because old plastic is cheaper.

Key Takeaway: Old plastic car parts can be turned into new ones to help the Earth.

Green Progress

| Action | Outcome | Impact |

|---|---|---|

| Reuse | Less waste | Clean Earth |

| Regrind | Cheap parts | Lower Price |

| Sort | Better quality | Strong Parts |

Recycling is a great way for your company to be kind to nature.

# 7. Does automotive injection molding need special car quality certificates?

Yes, making car parts requires a special certificate called IATF 16949 to show they are safe. You want to be sure that your parts will not fail on the road. Here is the deal. This paper proves that the factory follows very strict rules. Every part must be checked to make sure it is perfect. If a factory has this stamp, you know they care about quality and safety.

What the certificate means ● The factory is very clean. ● Workers check every single part. ● Machines are kept in good shape.

Wait, there is a catch. Getting this certificate takes a long time and a lot of hard work.

Key Takeaway: Special safety stamps like IATF 16949 mean the car parts are very high quality.

Quality Marks

| Name | Type | Importance |

|---|---|---|

| IATF 16949 | Automotive | Very High |

| ISO 9001 | General | High |

| UL Mark | Safety | Good |

Having the right papers makes customers trust your car parts much more.

# 8. How does automotive injection molding make car parts look smooth?

This process makes parts look smooth by using very shiny metal molds with no scratches. You want your car to look beautiful and shiny in the sun. But here is the kicker. This is called a “Class A” surface because it looks perfect like glass. Workers polish the steel mold until it shines. When the plastic touches the shiny steel, it becomes shiny too. You do not even need to paint some of these parts.

Ways to make it look good ● Polishing the mold with soft cloth. ● Adding a texture like leather. ● Using high heat for a gloss look.

Ready for the surprise? You can make plastic look just like wood or carbon fiber.

Key Takeaway: Smooth molds make car parts look shiny and expensive without extra paint.

Surface Types

| Style | Look | Use |

|---|---|---|

| High Gloss | Shiny | Mirrors |

| Textured | Bumpy | Dashboards |

| Matte | Flat | Engine Parts |

Beautiful parts make a car feel special and high-end for the driver.

# 9. What is the return on money for automotive injection molding?

The return on money is high because you can make millions of parts with one tool. You spend a lot of money on the steel mold at first. This is where it gets interesting. After the mold is finished, each plastic part costs only a few cents. If you make a lot of parts, you save a huge amount of cash. This makes it the best choice for cars that sell all over the world.

How to save money ● Making many parts at once. ● Using fast machines to save power. ● Reducing mistakes with smart computers.

What is the bottom line? The more you make, the cheaper each part becomes for you.

Key Takeaway: Spending money on a good mold helps you save a lot of money later.

Cost Savings

| Volume | Cost Per Part | Profit |

|---|---|---|

| Low | High | Low |

| Medium | Medium | Medium |

| High | Very Low | Very High |

Smart planning with your molds leads to big success for your business.

# 10. Where can you find a good automotive injection molding factory?

You can find a good factory by looking for teams with big machines and safe certificates. You need a partner who listens to your ideas and helps you. You might be wondering who to trust with your project. Look for a place that has worked on cars for many years. A good factory will show you their tools and explain how they keep parts safe.

What to look for ● Many years of car experience. ● Modern machines that work fast. ● Friendly people who answer calls.

Here is the final secret. Finding a good partner is the most important step for your car project.

Key Takeaway: Choosing a partner with the right skills makes your car parts perfect.

Partner Check

| Feature | Importance | Why? |

|---|---|---|

| Experience | Very High | Avoids mistakes |

| Speed | High | Meets deadlines |

| Support | High | Solves problems |

A great factory will help your business grow and make better cars.

Final Thoughts

We talked about how making plastic parts helps cars be light and quiet. Using the right tools saves you money and keeps the Earth clean. Our team at HST Tech is ready to help you with your next big job. Ready to start? We can build the best molds for your car parts today. If you need help, please contact us now. We want to be the reason your cars are the best on the road!

FAQ

Q1: Can I make metal parts with this machine? No, this machine is mostly for plastic, but some special ones use metal powder mixed with plastic.

Q2: What is the best plastic for a car dashboard? The best choice is often a mix of ABS and PC because it is strong and looks good in the sun.

Q3: How do I know if my part will break? We use computer tests to see where the part might be weak before we build the mold.

Q4: Can I change the color of my parts? Yes, we just add a small amount of color beads to the plastic before it melts in the machine.

Q5: How long does it take to make a new mold? It usually takes about four to eight weeks depending on how big and complex your car part is.