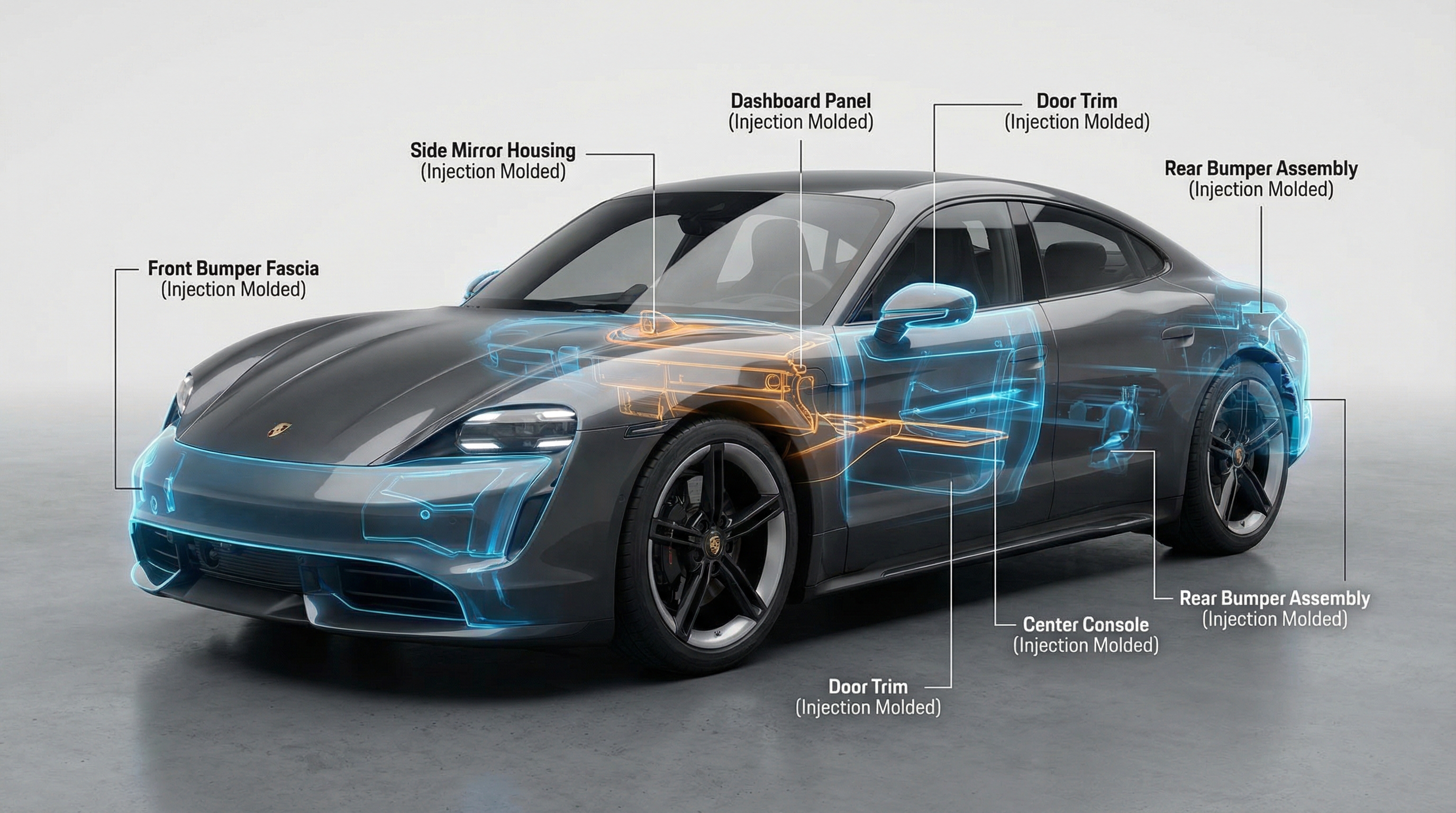

automotive injection molding: What It Is, How It Works, Uses, Process, and Advantages

automotive injection molding is a way to make plastic car parts by melting plastic and pressing it into a metal box. Making car parts is hard because they must be strong but also very light. If a car is too heavy, it uses a lot of gas and costs you more money at the pump. This is why automotive injection molding is the perfect solution because it makes light parts that are very tough.

What is the main goal of automotive injection molding?

The main goal of automotive injection molding is to create many perfect car parts in a very short time. It is very hard to build a car if every piece is a different size or shape. This process makes sure every part is a twin of the one before it. We use special tools to make sure your car parts fit together like building blocks.

Why do we need so many parts?

A car has thousands of tiny pieces that all have to work together to keep you moving. If one part is missing or broken, the whole car might not start at all.

- It helps make parts for the engine.

- It makes the buttons on your radio.

- It even makes the lights on the back of the car.

You might be wondering about the speed.

How fast can we make them?

Once the metal mold is ready, the machine can make a new part in less than a minute. This is much faster than making parts by hand with a hammer and saw.

- Machines work day and night.

- Thousands of parts are made every day.

- This keeps the price of cars lower for everyone.

Key Takeaway: Making many identical parts quickly is the secret to building great cars at a price people can afford.

| Goal | Why it Matters | |

|---|---|---|

| Speed | Makes more cars in a day | |

| Matching | All parts fit perfectly | |

| Low Cost | Saves money for the buyer |

This data shows that being fast and accurate is the most important part of making car pieces today.

Why is plastic best for automotive injection molding?

Using plastic for automotive injection molding is best because plastic is light and does not rust like metal. Metal is very heavy and can get brown and flaky when it gets wet. This can make a car look old and break down much sooner than it should. Our factory helps you pick plastics that stay strong for a very long time.

Is plastic strong enough?

Today, we have special plastics that are almost as strong as steel but much easier to shape. These plastics can handle bumps and hits without breaking into small pieces.

- It can bend without snapping.

- It stays strong in the hot sun.

- It does not crack in the cold snow.

Believe it or not.

How does it help save gas?

Since plastic is so light, the car does not need as much power to move down the road. This means you can drive much further using the same amount of fuel.

- Light cars go faster.

- Engines don’t have to work as hard.

- The car is better for the Earth.

Key Takeaway: Plastic is the best material for cars because it is light, strong, and keeps the car looking new.

| Material | Weight | Rusts? | |

|---|---|---|---|

| Steel | Very Heavy | Yes | |

| Plastic | Very Light | No | |

| Aluminum | Medium | No |

This table explains why car makers are choosing plastic more often than heavy metal parts.

What materials are used in automotive injection molding?

The materials used in automotive injection molding look like tiny colorful beads before they are melted down. If you use the wrong kind of bead, the part might be too soft or break too easily. This can lead to big problems when the car is driving on the highway. We help you pick the right beads so your parts are always safe.

What are the most common beads?

Most car parts use beads called ABS or Nylon because they can take a lot of heat and pressure. These beads come in any color you can imagine to match the car.

- ABS is great for shiny trim.

- Nylon is used for parts near the hot engine.

- Polypropylene is used for big bumpers.

Listen to this.

Can we make the beads stronger?

We can mix in tiny bits of glass or carbon to make the plastic beads even tougher. This makes the finished part very stiff so it does not wobble or bend.

- Glass fibers add strength.

- Color beads add beauty.

- Special chemicals stop sun damage.

Key Takeaway: Picking the right plastic beads is the first step to making a car part that will last forever.

| Bead Type | Best Use | |

|---|---|---|

| ABS | Dashboards and Knobs | |

| Nylon | Engine Covers | |

| PP | Bumpers and Doors |

Choosing the correct plastic ensures that the part will do its job without melting or breaking.

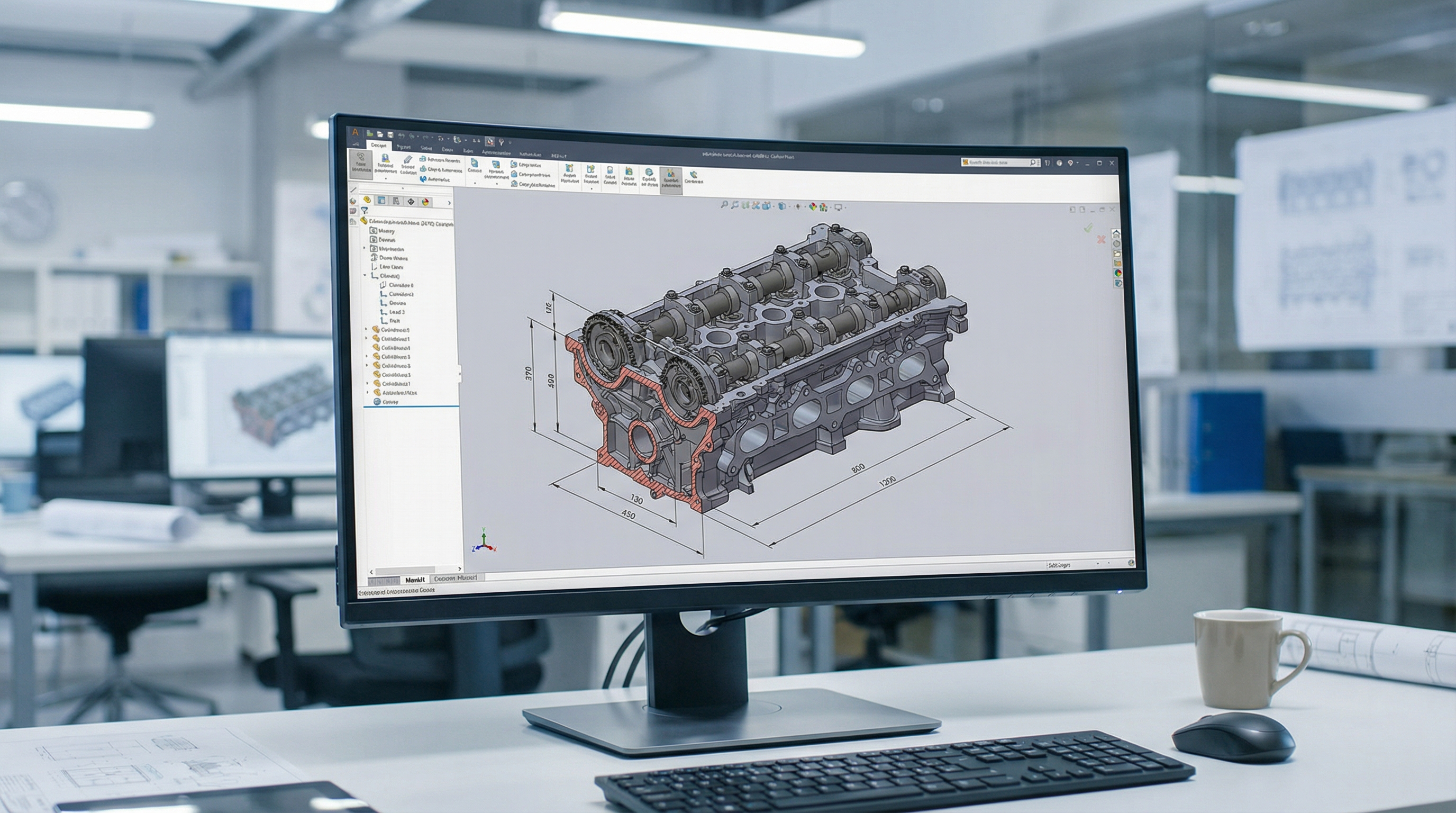

How do you design for automotive injection molding?

Designing for automotive injection molding means drawing the part on a computer before the machine starts. If the drawing has a mistake, the metal mold will be wrong and the parts will not work. This can waste a lot of money and time for your business. Our engineers at HST Tech look at your drawings to make sure they are perfect.

What is a 3D model?

A 3D model is a picture on a computer that you can turn around to see every side. It helps us see if the part is too thick or too thin in some spots.

- It shows the exact size.

- It finds mistakes early.

- It tells the machine what to do.

But wait, there is more.

Why do walls need to be even?

If one part of the wall is thicker than the other, the plastic will cool at different speeds. This can make the part look bumpy or bent instead of smooth and flat.

- Even walls cool faster.

- It stops the part from warping.

- The part looks much more professional.

Key Takeaway: A perfect computer drawing leads to a perfect metal mold and a perfect plastic car part.

| Design Step | Tool Used | |

|---|---|---|

| Drawing | Computer Software | |

| Checking | Stress Analysis | |

| Fixes | Engineering Review |

Using a computer to plan everything helps avoid big mistakes that could cost a lot of money later.

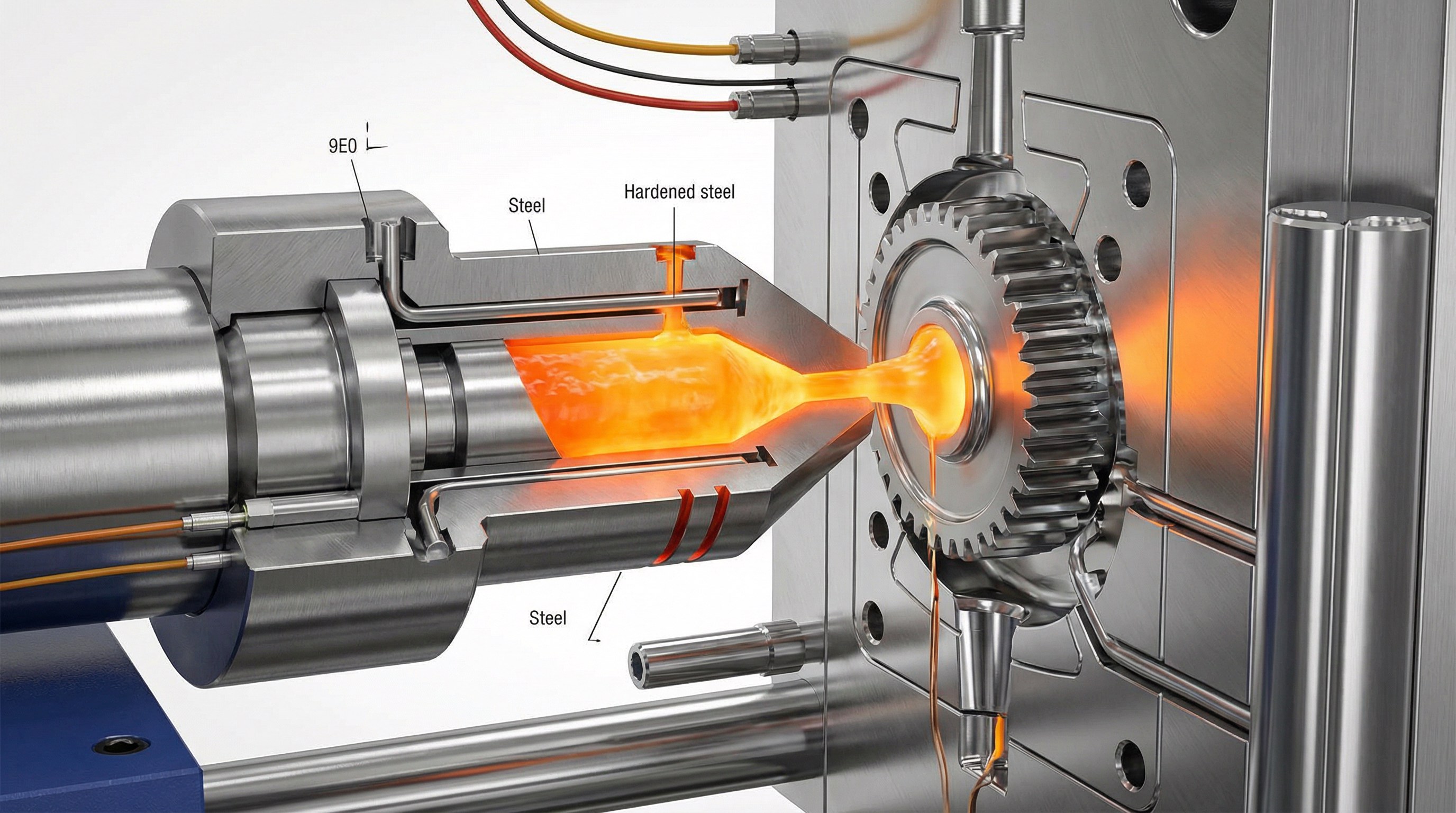

How does the machine finish automotive injection molding?

The machine for automotive injection molding is very big and uses a lot of power to squeeze the plastic. Sometimes parts can get stuck inside if the machine is not cleaned or set up the right way. This makes the factory stop working and slows down your order. Our machines are kept very clean so they never have to stop.

What does the screw do?

Inside the machine, a giant screw turns around to melt the plastic beads and push them forward. It works just like a big noodle machine that pushes dough through a hole.

- It creates high heat.

- It mixes the colors together.

- It pushes the liquid plastic fast.

You will love this.

How does the part come out?

When the plastic is hard, the metal mold opens up and small pins push the part out. Then the mold closes again and the machine starts the next part right away.

- Pins push the part gently.

- The part falls into a box.

- The cycle starts again in seconds.

Key Takeaway: A strong machine and a smart screw make it easy to turn hard beads into soft liquid and back again.

| Machine Part | What It Does | |

|---|---|---|

| Hopper | Holds the plastic beads | |

| Screw | Melts and pushes plastic | |

| Mold | Shapes the part |

The machine is like a giant robot that knows exactly how to make your car parts every time.

What is the step-by-step automotive injection molding plan?

The plan for automotive injection molding has many steps that we follow to make sure you are happy. If we skip a step, the parts might have bubbles or be the wrong color. This makes the parts look bad and you will not want to use them in your car. We follow a strict map to make sure every step is done right.

What is the first step?

The first step is making the metal mold out of very hard steel that can handle high heat. This mold is like a cake pan that gives the plastic its shape.

- We cut the steel with lasers.

- We polish it until it shines.

- We test it to make sure it works.

Do you see how it works?

What happens at the end?

After the parts are made, we check them one by one to make sure they are not broken or ugly. Only the best parts are put into boxes to be sent to your office.

- We measure every part.

- We look for scratches.

- We pack them very carefully.

Key Takeaway: Following a step-by-step plan is the only way to make sure your car parts are perfect.

| Phase | Main Task | |

|---|---|---|

| Pre-Work | Making the steel mold | |

| Production | Making the plastic parts | |

| Quality | Checking for mistakes |

This careful plan ensures that every part we send you is ready to be put on a car.

How does quality control help automotive injection molding?

Quality control in automotive injection molding means checking the parts to make sure they are safe for drivers. If a part breaks while someone is driving, it could cause a scary accident. This is why we test the parts with big machines to see how strong they really are. We want every person in a car to feel safe and happy.

How do we check for holes?

We use special cameras to look inside the plastic to see if there are any tiny air bubbles. Air bubbles make the part weak and easy to snap like a dry twig.

- Cameras see through the plastic.

- We look for hidden cracks.

- We throw away any bad parts.

Wait, there is more.

Why do we measure everything?

We use tools that can measure things smaller than a hair to make sure the part fits perfectly. If a button is too big, it will get stuck when you try to push it.

- Parts must be the right size.

- They must click into place.

- We keep a record of every test.

Key Takeaway: Checking every part with cameras and tools keeps drivers safe and makes cars last longer.

| Test | What We Look For | |

|---|---|---|

| Visual | Scratches or bad colors | |

| X-Ray | Bubbles inside the part | |

| Measure | Correct size and shape |

Testing is the most important step to make sure our parts never fail when they are on the road.

Can we make cool car insides with automotive injection molding?

We use automotive injection molding to make the inside of the car look beautiful and feel soft. If the inside of a car is made of rough metal, it will be very uncomfortable to sit in. This makes people not want to buy the car because it feels cheap and cold. Our parts make the car feel like a cozy room where you can relax.

Can we make different textures?

The metal mold can have patterns that make the plastic look like expensive leather or shiny wood. This gives the car a fancy look without costing a lot of extra money.

- Leather looks for the dash.

- Shiny silver for the handles.

- Smooth plastic for buttons.

You might be surprised.

Do we make the cup holders?

Yes, we make cup holders, air vents, and even the boxes where you keep your sunglasses. These parts have many moving pieces that must all fit together perfectly.

- Vents that slide easily.

- Cup holders that don’t spill.

- Door pockets for your maps.

Key Takeaway: Injection molding makes the inside of a car pretty, useful, and very comfortable for everyone.

| Interior Part | Special Feature | |

|---|---|---|

| Air Vent | Can move up and down | |

| Handle | Feels smooth to touch | |

| Button | Clicks when you push it |

These parts are what make a car feel like a high-quality product that people love to own.

Where do parts go after automotive injection molding?

After the automotive injection molding is done, the parts are stored in a large, clean building. If parts are just left outside, they can get dirty or crushed by big trucks. This would be a waste of all the hard work we did to make them. We keep them safe in our warehouse until you are ready for them.

How are they packed?

We use soft foam and strong boxes to make sure the parts do not touch each other during the trip. This prevents scratches that would make the new parts look old.

- Wrapped in soft plastic.

- Placed in thick boxes.

- Stacked neatly on pallets.

Listen to this.

How do they get to you?

We use big ships and planes to send the parts from our factory in China to your door. We handle all the paperwork so you don’t have to worry about anything.

- Tracked every mile of the way.

- Delivered right to your shop.

- Always arrives on time.

Key Takeaway: Protecting the parts in a warehouse and shipping them carefully means they arrive in perfect shape.

| Shipping Step | Goal | |

|---|---|---|

| Packing | Stop any scratches | |

| Storage | Keep parts clean | |

| Delivery | Arrive when promised |

Good logistics means your parts are always ready when you need to start building your cars.

Why is HST Tech a leader in automotive injection molding?

HST Tech is a leader in automotive injection molding because we have been doing this for over 10 years. Many other companies are new and might not know how to solve tricky problems. If your partner makes a mistake, your whole project could be late or cost too much. We use our experience to make sure your project is a big success.

Do we have a good team?

Our team of engineers knows exactly how to make the best molds and parts for your car. We talk to you every day to make sure we are doing exactly what you want.

- Engineers with 10+ years of work.

- Friendly people who help you.

- Experts who love making cars.

You can trust us.

Can we help you save money?

Because we own our factory, we don’t have to pay other people to do the work for us. This means we can give you a better price than companies that don’t have their own machines.

- Direct factory prices.

- No middleman fees.

- Free design help for you.

Key Takeaway: Choosing HST Tech means you get a team of experts who will help you save money and time.

| Why Choose Us | Benefit for You | |

|---|---|---|

| 10 Years Work | We know all the secrets | |

| Direct Factory | You pay much less money | |

| Fast Help | We answer you in 24 hours |

Our history and our team are the reasons why many famous car companies choose us to make their parts.

Conclusion

Automotive injection molding is the smartest way to make car parts that are light, strong, and beautiful. We talked about how we use computers to design parts, how big machines melt plastic beads, and how we check everything to keep you safe. We solved the problem of making cars too heavy by using high-quality plastic instead of metal. Our team at HST Tech is ready to help you with your next big car project today. We promise to make your parts perfectly and send them to you fast. Please contact us today to start making your car ideas come to life!

FAQs

Can I choose any color for my car parts?

Yes, you can. We can mix special color beads into the plastic to make your parts match any color you like.

What is the best plastic for an engine part?

Nylon is the best choice for engines. It is very strong and does not melt even when the engine gets very hot.

How do I know if my parts will fit?

We check your design on a computer first to make sure every piece fits perfectly. We also measure the real parts with special tools before we ship them.

How many parts can I make with one mold?

You can make hundreds of thousands of parts. Our steel molds are very tough and can be used over and over for many years.

Why is HST Tech better than other factories?

We have over 10 years of experience and we own our own machines. This means we can give you better quality and a lower price than anyone else.