Automotive injection molding is a special way to make plastic car parts by melting plastic and squishing it into a metal shape. Building a car is very hard because it needs thousands of tiny pieces to work together. If just one small button or handle breaks, it can make your whole day difficult and frustrating. You need a way to make parts that are strong, cheap, and perfect every single time. That is why automotive injection molding is the best solution for making everything from dashboards to cup holders.

What is automotive injection molding exactly?

It is a way to make many plastic pieces that look the same using a giant metal tool called a mold. This process helps car makers build thousands of parts in just one day.

How do we start the process?

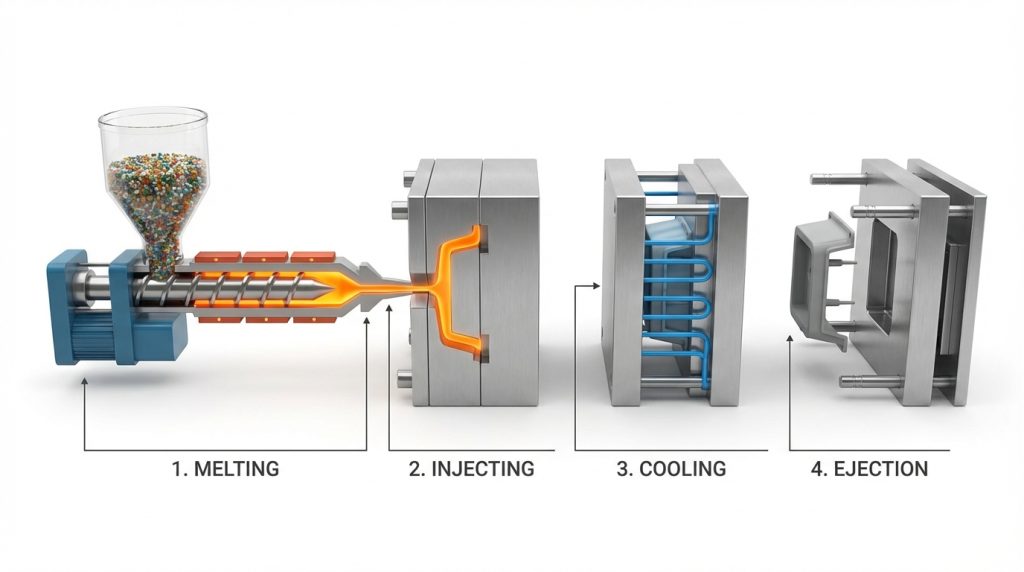

We start by taking tiny plastic beads and putting them into a big machine. These beads are very hard and look like small colorful rocks.

Listen to this:

- The machine heats the beads until they melt.

- The melted plastic looks like thick, gooey honey.

- It is then ready to be pushed into the mold.

What does the mold do?

The mold is a hollow piece of steel that is shaped like the car part you want to make. When the liquid plastic goes inside, it takes that exact shape.

You will love this:

- The mold stays closed very tight so no plastic leaks out.

- It can make very complex shapes that are hard to build by hand.

- Every part comes out looking exactly like the one before it.

Key Takeaway: Using a metal mold ensures that every car part is identical and made very quickly.

| Part of Process | What it Does | |

|---|---|---|

| Plastic Beads | The starting material for parts | |

| Heating | Turns hard beads into liquid | |

| Steel Mold | Gives the plastic its final shape |

This simple method is the secret to why cars have so many neat plastic pieces inside.

Why do we use automotive injection molding for cars?

We use automotive injection molding because it makes car parts very light and helps save money for the people who buy cars. When a car is lighter, it can go faster and use less fuel.

Does it make cars safer?

Yes, because plastic parts can be made very strong to protect the people sitting inside. Plastic does not rust like metal does when it gets wet from the rain.

Check this out:

- Molded plastic can soak up energy during a small bump.

- It keeps the inside of the car very quiet while you drive.

- These parts last a long time without breaking.

Is it a fast way to work?

This is one of the fastest ways in the world to make things for a car. Once the metal mold is ready, the machine can make a new part every few seconds.

Wait for it:

- Machines can work all night without getting tired.

- Making many parts at once makes the price lower for everyone.

- It helps car companies finish building cars much sooner.

Key Takeaway: Molding makes cars lighter, safer, and much cheaper for families to buy.

| Benefit | Why it Matters | |

|---|---|---|

| Lightweight | Saves money on gas or battery power | |

| No Rust | The car looks good for many years | |

| Fast Speed | Thousands of parts made every day |

These benefits are the reason why almost every car on the road is full of plastic parts.

How does the liquid plastic change into a car part?

Liquid plastic turns into a car part by getting very cold inside the metal mold. This process of automotive injection molding is like making ice cubes in your freezer.

How does the plastic get hard?

The metal mold has cold water running through it to chill the hot plastic. As the plastic cools down, it gets very hard and solid.

Think about this:

- The plastic stays in the mold for just a few seconds.

- It goes from being soft and gooey to being a strong part.

- This helps the part keep its perfect shape forever.

How does the part come out?

When the plastic is hard, the two sides of the metal mold slide apart. A small pin pushes the part out, and it falls into a box.

Guess what:

- The part is ready to be used on a car right away.

- The mold then closes and starts the whole thing over again.

- It is a cycle that never has to stop.

Key Takeaway: Cooling the plastic inside the mold is what makes the part strong and ready to use.

| Step | What Happens | |

|---|---|---|

| Injection | Liquid plastic is squished into the mold | |

| Cooling | Cold water makes the plastic hard | |

| Ejection | The finished part pops out of the machine |

Watching the parts pop out of the machine is one of the coolest things to see in a factory.

Which car parts come from a machine mold?

Many parts like your dashboard, radio buttons, and big bumpers are all made using automotive injection molding . You can find these molded parts in every corner of your family vehicle.

What parts are inside the car?

The inside of a car needs to be smooth and comfortable for your hands to touch. Designers use molds to make the cabin look beautiful.

Look at this:

- The cup holders that hold your drinks are molded.

- The handles you use to open the door are made this way too.

- Even the covers for the air vents come from a mold.

What parts are on the outside?

The outside of the car needs parts that can stand up to the sun and wind. Molding helps make these parts tough and shiny.

But wait, there’s more:

- The big bumpers on the front and back are molded plastic.

- The clear covers over the headlights are made in a mold.

- Small trim pieces make the car look sleek and fast.

Key Takeaway: From the buttons you press to the bumpers that protect you, molding is everywhere.

| Area | Example Molded Parts | |

|---|---|---|

| Interior | Dashboards, buttons, and handles | |

| Exterior | Bumpers, light covers, and mirrors | |

| Engine | Fluid tanks and wire covers |

Without these parts, cars would be much heavier and would not look as nice as they do now.

Why must car parts be made perfectly every time?

Parts must be perfect so they fit together tightly and don’t make any loud rattling noises while you drive. High-quality automotive injection molding ensures that every piece is the exact right size.

What happens if a part is wrong?

If a part is even a tiny bit too big, it might not fit into the car correctly. This could cause a leak or make a part fall off later.

Check this out:

- Perfect parts make the car feel very high-quality.

- They keep the wind and rain from coming inside the cabin.

- Everything stays in place even when you drive over bumps.

How do we measure the parts?

We use special tools and computers to check the size of every part that comes out. We want to make sure there are no mistakes at all.

You won’t believe it:

- Cameras can see tiny scratches that people might miss.

- Computers check if the plastic is the right thickness everywhere.

- Only the very best parts are allowed to go to the car factory.

Key Takeaway: Making parts perfectly every time keeps your car quiet, dry, and safe to drive.

| Goal | Why it Matters | |

|---|---|---|

| Perfect Fit | No rattling or annoying noises | |

| Tight Seals | Keeps the rain out of your car | |

| High Quality | The car lasts for a very long time |

Companies like HST-Tech work very hard to make sure every single part is just right.

What kind of plastic is used for car parts?

Engineers use special plastic beads for automotive injection molding that can stay strong even when the car engine gets very hot. Not all plastic is the same, so we have to pick the right one for each job.

Are there different types of plastic?

Yes, some plastics are very hard like a rock, while others are soft and can bend. We use the soft ones for buttons and the hard ones for the engine.

Here is the best part:

- Some plastic can handle the freezing cold winter.

- Other plastic can stay strong in the middle of a hot desert.

- We can even make plastic that looks like shiny chrome metal.

Can plastic be as strong as metal?

We can add tiny pieces of glass to the plastic to make it super tough. This makes it strong enough to hold heavy things without breaking.

Wait for it:

- This “super plastic” is much lighter than heavy steel.

- It helps the car stay strong if it ever gets into an accident.

- It is much easier to shape into cool designs than metal is.

Key Takeaway: Picking the right plastic ensures that every part can do its job in any weather.

| Type of Plastic | Where we Use it | |

|---|---|---|

| Heat Resistant | Near the hot car engine | |

| Soft Touch | On buttons and the steering wheel | |

| Extra Strong | For parts that hold the car together |

By using different types of beads, we can make every part of the car work perfectly.

How do molds help make cars better for the planet?

Using plastic molds makes cars lighter so they use less gas and don’t hurt the air as much. This is a big part of how automotive injection molding helps protect our Earth.

Can we reuse the extra plastic?

One of the best things about this process is that we can recycle the plastic. If a part is not perfect, we can melt it down and try again.

Think about this:

- This means we don’t throw away a lot of trash.

- We can use old parts to make brand-new parts for new cars.

- It helps keep the planet clean for everyone to enjoy.

Does it help the air stay clean?

Because plastic parts are light, the car’s engine does not have to work as hard. This means less smoke comes out of the back of the car.

Guess what:

- Lighter cars help us save the world’s fuel.

- It is a smart way to build cars that are friendly to nature.

- Even the factories are becoming better at using less electricity.

Key Takeaway: Molding helps us build cars that are kind to the environment and keep the air fresh.

| Green Fact | How it Helps Earth | |

|---|---|---|

| Recyclable | Less plastic goes into the trash | |

| Lightweight | Cars burn less fuel and save energy | |

| Less Waste | Factories use every bit of material |

We can have amazing cars and a beautiful planet at the same time by using smart molding.

Can molding make parts for electric cars?

Yes, automotive injection molding is very important for electric cars because it helps protect the heavy batteries. Electric cars need to be very light so they can drive a long way on one charge.

How does it help the battery?

The big battery in an electric car is very heavy and needs a strong home. We use plastic molds to make protective boxes for these batteries.

Look at this:

- The plastic box keeps the battery safe from road rocks.

- It also keeps the battery from getting too hot or too cold.

- Plastic does not let electricity leak out where it shouldn’t go.

Is it better for long trips?

When an electric car is made of light plastic parts, it can travel more miles before it needs to plug in. This makes driving an electric car much easier for families.

But wait, there’s more:

- Light cars are easier to stop and turn on the road.

- Plastic parts help make the car very quiet inside.

- It helps the car stay safe and fun for a long time.

Key Takeaway: Molding is the secret to making electric cars that can go further and stay safer.

| Electric Car Part | Why it is Molded | |

|---|---|---|

| Battery Case | To keep the battery safe and dry | |

| Charging Port | To hold the plug in the right spot | |

| Motor Cover | To keep the motor clean and quiet |

Electric cars are the future, and plastic molding is the tool we use to build them.

Why is HST-Tech a leader in car part molds?

HST-Tech is a leader in automotive injection molding because they use smart computers to design the best molds. They have a team of experts who know exactly how to make a car part perfect.

Do they use the best machines?

Yes, they use very expensive and high-tech machines to make their molds. This ensures that every part made with an HST-Tech mold is world-class.

Check this out:

- Their machines are very precise and never make mistakes.

- They can make molds for very large parts like bumpers.

- They also make tiny molds for the small buttons in your car.

Do they help car companies?

HST-Tech works closely with the people who design cars to solve hard problems. They help find ways to make parts lighter and stronger.

Wait for it:

- They listen to what the car makers need.

- They use their experience to make parts even better.

- They care about making cars safe for your family.

Key Takeaway: Choosing a top partner like HST-Tech means getting the best parts for your vehicle.

| Partner Quality | Why it Matters to You | |

|---|---|---|

| Expert Team | They know how to fix any problem | |

| Best Machines | The parts come out looking perfect | |

| Experience | They have been making car parts for a long time |

Working with the best people is how you build a car that everyone wants to drive.

How do we check if a car part is good?

We check parts by using lasers and smart sensors to make sure everything is safe for the Earth. Quality is the most important part of automotive injection molding .

Do we use robots to check?

Yes, robots with cameras can look at a part much faster than a human can. They make sure there are no holes or bumps that shouldn’t be there.

Think about this:

- Robots can check thousands of parts every hour.

- They never get tired or blink and miss a mistake.

- This keeps the quality very high for every single car.

Why is this good for you?

When parts are checked carefully, it means your car will not break down. You can trust that your car is safe when you go on a long trip.

You won’t believe it:

- Every handle will work and every button will click.

- The dashboard will stay looking brand new for years.

- You won’t have to spend money fixing broken plastic pieces.

Key Takeaway: Careful checking ensures that every part in your car is ready for the road.

| Check Point | What we Look For | |

|---|---|---|

| Surface Look | No scratches or weird marks | |

| Exact Size | It fits into the car just right | |

| Strength | It won’t break when you use it |

Testing every piece is the final step in making a great car for you to enjoy.

Simple FAQ Section

Can I use any plastic for car parts?No, because every part has a different job. Engineers pick special plastics that can handle heat, cold, or being very strong based on where the part goes.

What’s the best way to make a lot of parts?Injection molding is the best and fastest way. It allows a factory to make thousands of the exact same part in just one day.

How do I know if a part is high quality?You can tell because it will feel smooth and fit perfectly. A good part will not have any gaps or make noise when you touch it.

Can plastic parts really be strong?Yes, they are very tough! Some plastics are mixed with tiny bits of glass to make them as strong as metal but much lighter.

What’s the fastest way to start making a car part?The fastest way is to talk to an expert company like HST-Tech. They can help you design a mold and start your machines very quickly.

Conclusion

Automotive injection molding is the amazing process that helps us build the cars we drive every day. It makes our vehicles lighter, safer, and much more affordable by using smart molds and recycled plastics. Without this technology, cars would be much harder to build and much more expensive for everyone.

At HST-Tech, we are proud to be a leader in making the molds that build the future of cars. We care about every tiny detail to make sure your family stays safe and happy on the road. If you have big ideas for new car parts, please contact us today! We are ready to help you turn your drawings into real, high-quality parts that will drive the world forward. Our mission is to provide the best tools so that every car on the road is built with perfection and care.