Imagine you want to make one thousand plastic toy cars by hand. It would take a very long time, and some cars might look a little bit different or messy. You might get tired and make mistakes, which means some toys would break easily.

Luckily, Plastic injection molding is the perfect solution for making lots of things quickly and perfectly. This special process uses a big machine to melt plastic and squish it into a shape. It is like using a magic machine that makes perfect toys every single time you press a button!

What is Plastic Injection Molding?

Plastic injection molding is a way to make parts by melting plastic and pushing it into a metal box called a mold. This process is used to make everything from bottle caps to car parts very quickly. You can think of it like making Jell-O in a specific shape.

Is it like a 3D printer?

You might wonder if this is the same as 3D printing. While both make plastic things, Plastic injection molding is much faster for making thousands of items.

Check this out. A 3D printer builds one layer at a time, but a mold makes the whole part at once. It is the best way to fill a whole store with toys!

Key Takeaway: Injection molding is a super-fast way to make many identical plastic parts.

| Feature | Molding | 3D Printing | |

|---|---|---|---|

| Speed | Very Fast | Slow | |

| Amount | Thousands | One at a time |

This table shows that molding is better when you need a lot of items quickly.

What Materials Are Used Most?

Plastic injection molding uses tiny plastic beads called resins that melt when they get hot. Most machines use a type of plastic that can melt and then get hard again many times. This makes it easy to fix mistakes or recycle old parts.

Can we use hard plastic?

Yes, we use strong plastics to make items like helmets or phone cases. These materials are very tough and can stay strong for a long time.

Guess what? Some plastics are even used to make automotive injection molding parts that go inside real cars. These parts have to be very safe and strong for driving.

Key Takeaway: Choosing the right plastic beads helps make the part strong or flexible.

| Plastic Type | Use | Feel | |

|---|---|---|---|

| Hard | Helmets | Stiff | |

| Soft | Buttons | Squishy |

Selecting the best material ensures the final product works exactly like it should.

How Does the Machine Work?

The machine for Plastic injection molding works by using a giant screw to push melted plastic forward. It has a big heater that turns the hard plastic beads into a hot liquid. Once the plastic is like honey, the machine squishes it into the mold.

What does the screw do?

The screw is the most important part because it mixes the plastic and keeps it moving. It turns around and around to make sure the plastic is melted evenly.

But wait, there’s more. The screw also acts like a giant needle to inject the plastic into the metal shape. This is how Plastic injection molding gets its name!

Key Takeaway: The machine uses heat and a big screw to turn beads into liquid.

| Machine Part | Job | |

|---|---|---|

| Hopper | Holds the beads | |

| Heater | Melts the plastic | |

| Screw | Pushes the liquid |

Each part of the machine must work together to create a perfect plastic piece.

What Happens During the Cycle?

The cycle for Plastic injection molding is the set of steps the machine takes to make one part. First, the mold closes tight, then the plastic goes in, and then it waits to get cold. Finally, the mold opens, and the new part pops out!

Does it take a long time?

Actually, the whole cycle usually takes only a few seconds to a minute. Most of the time is spent waiting for the hot plastic to cool down and get hard.

Think about it. If a machine makes a part every ten seconds, it can make hundreds in just one hour! This speed is why we have so many plastic things around us.

Key Takeaway: The cycle is a fast loop of melting, squishing, cooling, and popping.

| Cycle Step | What Happens | |

|---|---|---|

| Injection | Plastic goes in | |

| Cooling | Part gets hard | |

| Ejection | Part falls out |

By repeating these steps, factories can fill big boxes with products in no time.

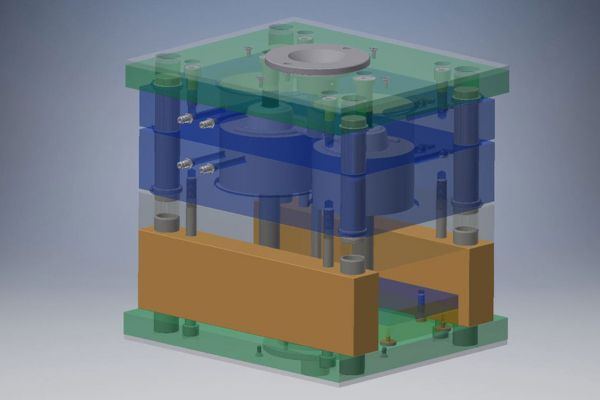

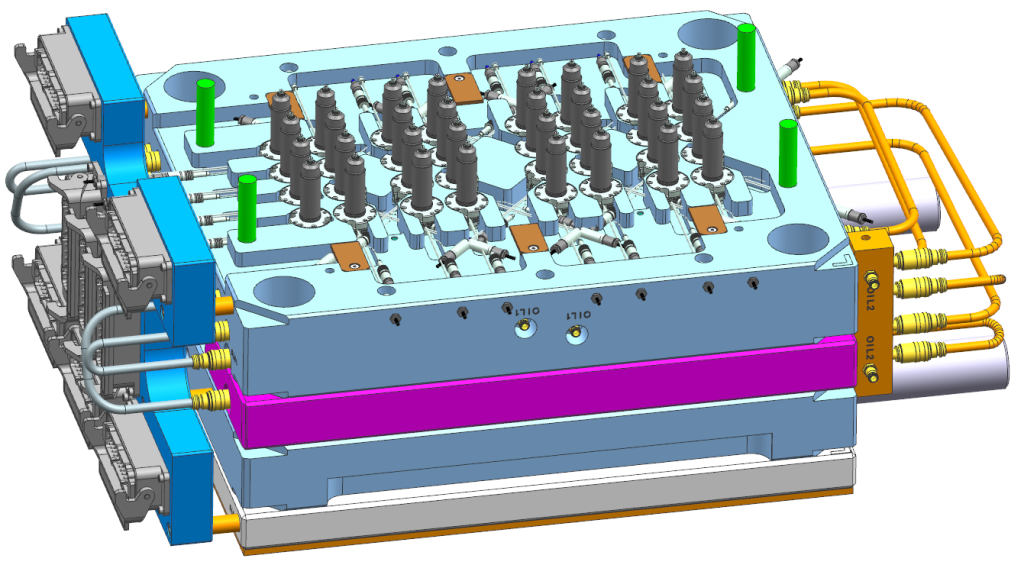

Why is the Mold So Important?

In Plastic injection molding, the mold is the metal tool that gives the plastic its shape. It is usually made of very strong steel so it doesn’t break under pressure. Creating a good mold is like making a perfect cookie cutter for plastic.

Is the mold made of steel?

Yes, most molds are made of steel because it can handle a lot of heat and pushing. Expert workers use injection mold tooling to carve tiny details into the metal.

Here is the best part. A single steel mold can be used to make over a million parts before it wears out! That makes it a very smart investment for a company.

Key Takeaway: A strong metal mold is the secret to making parts that all look the same.

| Mold Material | Benefit | |

|---|---|---|

| Steel | Lasts a long time | |

| Aluminum | Heats up fast |

The quality of the mold determines how beautiful and smooth your plastic part will be.

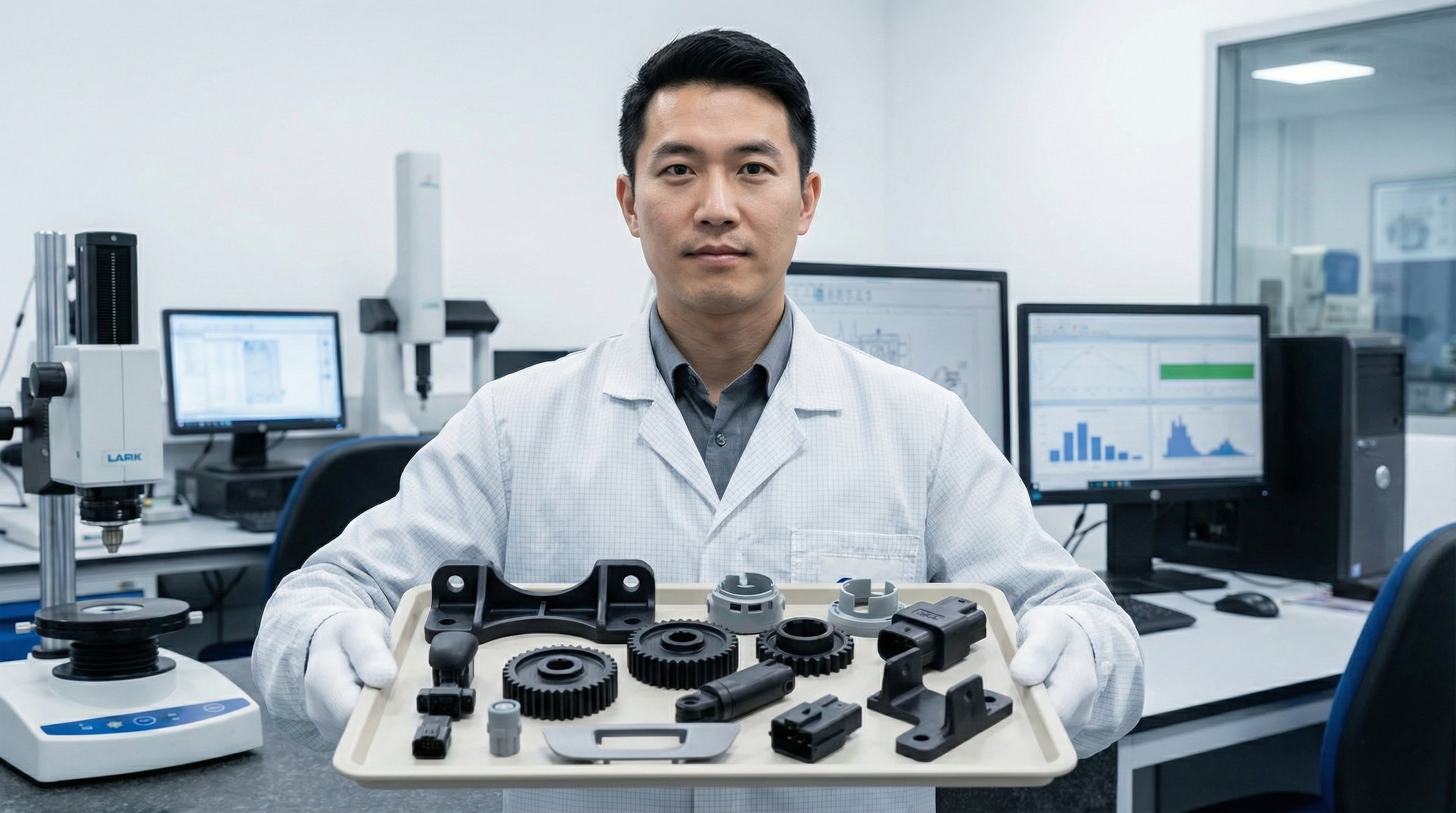

How Do We Control the Quality?

Controlling the quality in Plastic injection molding means checking every part to make sure it is perfect. Workers use special cameras and rulers to look for tiny mistakes. If a part is too small or has a bubble, they fix the machine.

Do we use special tools?

Engineers use very precise tools to measure parts down to a tiny fraction of an inch. They want to make sure every piece fits perfectly with other pieces.

You should know this. Even a tiny mistake can make a toy not fit together, so quality check is very important. Computers help the workers catch these mistakes before the toys go to the store.

Key Takeaway: Quality control keeps the parts safe and ensures they work correctly.

| Check Type | Tool Used | |

|---|---|---|

| Size | Digital calipers | |

| Weight | Electronic scale |

Using these tools helps maintain high standards for every single item produced in the factory.

What Are the Best Advantages?

The biggest advantage of Plastic injection molding is that it is very cheap when you make a lot of items. Once you have the mold, making the parts is very fast and doesn’t waste much plastic. It also lets you make very complicated shapes that would be hard to carve.

Is it good for the planet?

Many factories now recycle the extra plastic bits to make new plastic part manufacturing pieces. This means less trash and more ways to reuse materials.

Look at it this way. Since the machine is so precise, it only uses exactly the amount of plastic needed. This helps save money and protects our environment at the same time.

Key Takeaway: Molding is fast, saves money, and can be very friendly to the earth.

| Advantage | Why It Matters | |

|---|---|---|

| Low Cost | Saves money | |

| High Speed | Saves time | |

| Detail | Makes cool shapes |

These benefits make this process the number one choice for most companies today.

Can We Fix Common Problems?

Sometimes Plastic injection molding can have problems like “sink marks” or “flash.” A sink mark is a little dent where the plastic stayed hot too long. Flash is when extra plastic leaks out of the mold like messy edges.

What are sink marks?

Sink marks happen when the middle of a thick part stays hot while the outside gets cold. The plastic shrinks and pulls the surface inward, creating a small dip.

Want to know the fix? Engineers can change the temperature or press the plastic harder to keep it flat. It is all about finding the perfect balance of heat and pressure.

Key Takeaway: Most plastic mistakes can be fixed by changing how the machine runs.

| Problem | Simple Fix | |

|---|---|---|

| Sink Mark | Lower the heat | |

| Flash | Clamp mold tighter |

Fixing these small issues ensures that every part comes out looking smooth and professional.

Where Do We Use These Parts?

We use Plastic injection molding for almost everything you touch during the day. Your toothbrush, the buttons on your TV remote, and even the dashboard in your dad’s car are made this way. It is the most common way to make plastic things in the world.

Are there car parts?

Yes, many parts in cars are made using this fast process to keep them lightweight. Using plastic instead of heavy metal helps cars go faster and use less gas.

The truth is. You can find automotive injection molding parts in the seats, the doors, and even under the hood. It makes cars safer and much more comfortable for everyone inside.

Key Takeaway: This process makes the everyday items that make our lives easier and better.

| Industry | Example Part | |

|---|---|---|

| Toys | Building blocks | |

| Medical | Plastic syringes | |

| Home | Food containers |

From your kitchen to the hospital, molded plastic is everywhere helping people every day.

Why Is Automation the Future?

Automation in Plastic injection molding means using robots to help the machines work even better. Robots can pick up the hot parts and put them in boxes without ever getting tired. This makes the factory safer and much more efficient.

Do robots help us?

Robots are great because they can do the same job exactly the same way every time. They don’t make mistakes like humans might when they are sleepy.

Believe it or not. Some factories can run all night long with only robots and computers working! This helps make products cheaper so more people can afford to buy them.

Key Takeaway: Robots make manufacturing faster, safer, and much more accurate for the future.

| Benefit | Human | Robot | |

|---|---|---|---|

| Break time | Needs lunch | Never stops | |

| Precision | Very good | Perfect |

Smart machines and robots are changing the way we make everything in our world.

FAQ

Can I make my own plastic mold at home?No, because the machines need to be very hot and have lots of pressure. It is best to let professional factories with big machines do the hard work.

What’s the best plastic for toys?Yes, plastics like ABS are the best because they are strong and come in bright colors. They are safe to play with and do not break easily when dropped.

How do I know if a part is molded?Check for a tiny circle or a thin line on the plastic. These marks show where the plastic went into the mold or where the mold opened.

Can I recycle molded plastic parts?Yes, most of these parts can be melted down to make brand new things. Just look for the recycling symbol on the bottom of the plastic item.

What’s the best way to start a big project?Yes, the best way is to talk to an expert who knows how to build molds. They can help you design a part that is easy and cheap to make.

Conclusion

In this article, we learned how Plastic injection molding turns tiny beads into the toys and tools we use every day. We solved the problem of making many parts slowly by using fast machines and strong metal molds. Whether it is making car parts or medical tools, this process is the heartbeat of modern manufacturing. At HST-Tech, we believe in making high-quality parts that help the world move forward. If you need help with your next big idea, please contact us today to see how we can bring your designs to life. Our mission is to provide the best engineering solutions to make every product perfect for you!