Plastic injection molding is a way to make many identical plastic parts by melting plastic and pressing it into a metal shape. Making plastic parts can be very expensive and slow if the quality is bad. You might face delays or find broken parts that hurt your business and make customers unhappy. Plastic injection molding from HST Tech solves these problems by making perfect parts every time at a low cost. Our expert team uses high-tech machines to turn your ideas into real products quickly and safely.

What is Plastic injection molding?

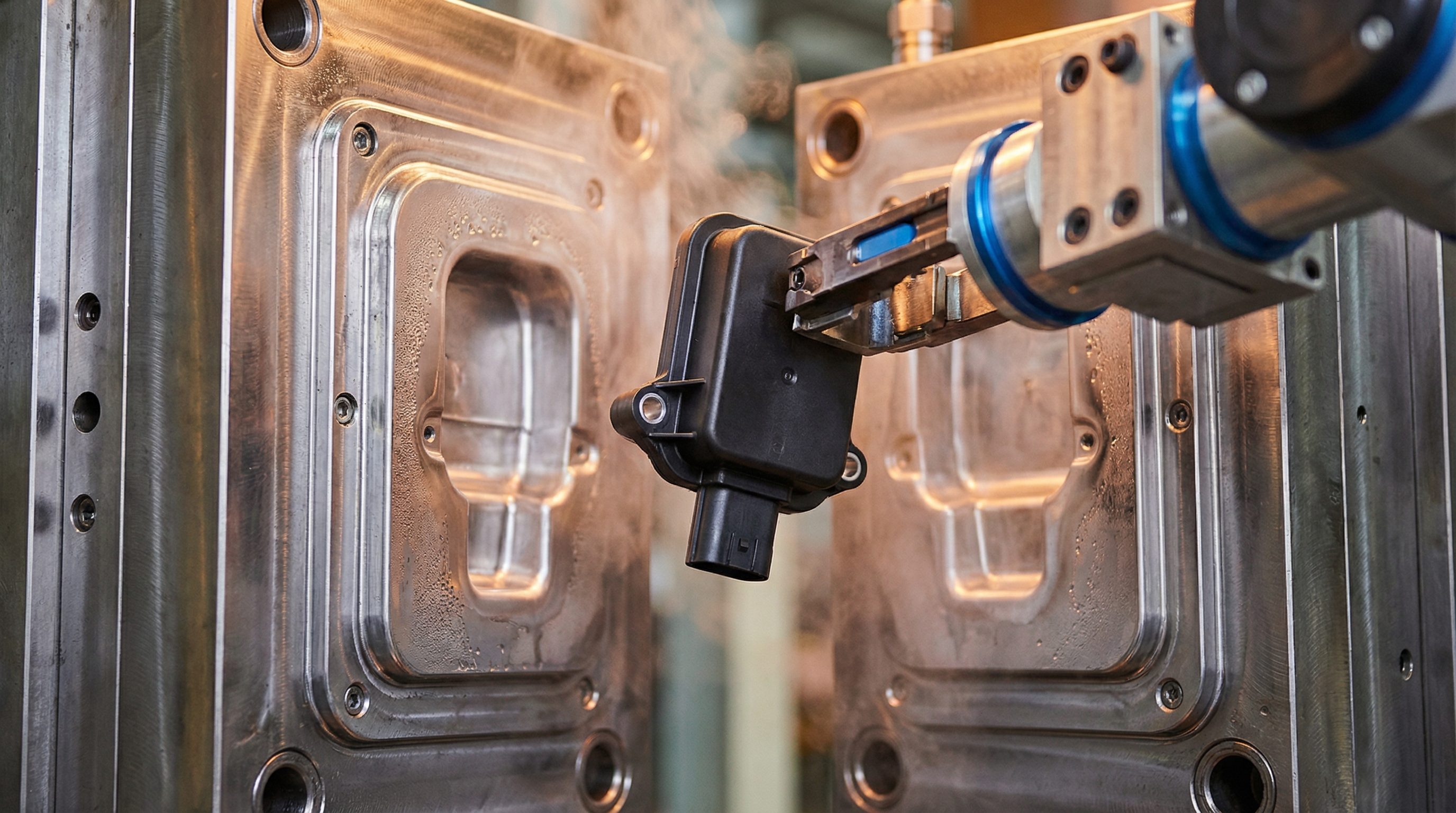

Plastic injection molding is a process that fills a hollow metal block with hot, liquid plastic to create a specific part. It is the most common way for companies to make things like toys, car parts, and bottle caps.

Why do companies use this method?

Do you need to make thousands of the same item? This method is perfect because it is very fast and makes every part look exactly like the first one.

- It saves time on big orders.

- It makes parts that are very strong.

- It uses almost all the plastic with very little waste.

You see, this is the best way to grow your business without spending too much money.

How does it help your business?

Have you ever worried about parts not fitting together? Our process at HST Tech keeps things very precise so every piece fits perfectly in your assembly.

- It reduces the need for hand-fixing parts.

- It keeps your production line moving fast.

- It helps you get products to stores sooner.

Think about this: once the mold is ready, the cost for each part becomes very small.

Key Takeaway: Using this process helps you make high-quality parts for less money as you grow.

| Feature | How it helps you | |

|---|---|---|

| High Speed | You get your parts delivered faster. | |

| Low Cost | You save money on every part you make. | |

| High Detail | Your parts look professional and clean. |

This table shows why most big businesses choose this method for their products.

How does the Plastic injection molding process work?

The Plastic injection molding process works like a giant hot glue gun that fills a metal box to make a shape. First, plastic beads are melted until they are like thick syrup. Then, a big machine squirts that liquid into a cold metal mold where it turns back into a solid.

What are the steps inside the machine?

The machine goes through a few simple steps very quickly. It starts by squeezing the mold shut and then injecting the hot plastic.

- Melting the plastic beads.

- Pushing the liquid into the mold.

- Waiting for the plastic to get cold.

- Opening the mold to let the part out.

It gets better because the machine can do this over and over all day and night.

Is the cooling part important?

Does it really matter how fast the plastic cools down? Yes, because if it cools too fast or too slow, the part might bend or break.

- Cooling makes the part hard and strong.

- Correct cooling keeps the shape perfect.

- It allows the part to be popped out safely.

Believe it or not, the cooling time is usually the longest part of the whole job.

Key Takeaway: A careful process ensures that every part is strong and ready for your customers to use.

| Process Step | What happens | |

|---|---|---|

| Injection | Hot plastic fills up every tiny corner. | |

| Cooling | The plastic turns into a hard solid. | |

| Ejection | The finished part falls out of the machine. |

Following these steps exactly is how we keep our quality so high for you.

Why choose Plastic injection molding for your parts?

You should choose Plastic injection molding because it lets you create complex shapes that other methods cannot handle. It is very reliable, which means you won’t have to deal with broken parts or messy designs. At HST Tech, we make sure your automotive injection molding parts meet the highest safety rules.

Can it make my parts look better?

Are you looking for a smooth or shiny finish on your products? This method allows us to make parts that feel premium and look beautiful.

- You can choose many different colors.

- You can make the surface smooth or rough.

- It adds fine details like logos very easily.

The best part is that the finish is part of the mold, so you don’t need to paint them.

Is it strong enough for hard work?

Do you need parts that can take a lot of heat or pressure? We can add special materials like glass fibers to the plastic to make it as strong as metal.

- Parts won’t crack under heavy weight.

- They can stand up to high heat.

- They last a very long time in the sun.

Key Takeaway: Choosing this method gives you the best mix of beauty and strength for any product.

| Benefit | Why it matters | |

|---|---|---|

| Great Finish | Your products look better than the competition. | |

| Strong Parts | Your customers will trust your brand more. | |

| Consistency | Every part in the box is exactly the same. |

These benefits are why we are a top choice for buyers in Europe and America.

What materials are used in Plastic injection molding?

Plastic injection molding uses small plastic beads called “resins” that come in many different types. Some are soft like rubber, while others are hard like a helmet. We help you pick the right beads so your part works exactly the way you want it to.

Which plastic is best for my part?

Have you wondered which plastic to use for a phone case or a car light? Different plastics do different jobs, like resisting heat or being very clear.

- ABS: Very strong and great for electronics.

- PP: Good for things that need to bend a lot.

- PC: Clear like glass but very hard to break.

Here is the thing: choosing the right material is the first step to a great product.

Can we add things to the plastic?

What if you need a specific color or a part that doesn’t catch fire? We can mix in “additives” to change how the plastic acts and looks.

- Colorants make your parts any color you want.

- UV blockers keep colors from fading in the sun.

- Flame retardants make the parts safer near heat.

Key Takeaway: Having many material choices means you can build a product for any environment or use.

| Material | Best Use | |

|---|---|---|

| ABS | Tough cases and toy blocks. | |

| Nylon | Strong gears that move a lot. | |

| TPE | Soft grips and flexible seals. |