Plastic injection molding is a way to make thousands of plastic parts that look exactly the same using a metal mold. Making plastic parts for your business can feel very hard when you don’t have the right tools. If your parts are weak or break easily, your customers will be unhappy and you might lose money. But wait, here is the good news: Plastic injection molding from HST Technology makes every part perfect so you never have to worry. We use high-quality machines to turn your big ideas into real products that last a long time.

What exactly is plastic injection molding?

Plastic injection molding is a process where we melt plastic and push it into a metal shape to make products. It is the most popular way to make everything from toy cars to bottle caps. We use a giant machine that works like a super-powered glue gun. This method lets us make many items very fast without any mistakes.

You can think of this process just like baking shaped cookies in a kitchen.

But wait, there is a difference:

- Instead of dough, we use hot, liquid plastic.

- Instead of a tray, we use a heavy steel mold.

- The plastic cools down and becomes very hard.

You will see that every piece comes out looking exactly like the one before it!

Why do people use it so much?

People love this method because it is the fastest way to create a huge pile of parts.

Believe it or not:

- One machine can make thousands of parts in a single day.

- The parts are very strong and do not break easily.

- We can make very tiny parts or very big parts.

This makes it perfect for big companies that need to sell millions of items.

| Feature | Why It Is Great | |

|---|---|---|

| Speed | Makes parts in just a few seconds | |

| Accuracy | Every part is a perfect twin | |

| Cost | It is cheaper when you make a lot |

This process ensures that your products are always high quality and ready for your customers.

Key Takeaway: Injection molding is a fast and smart way to turn liquid plastic into perfect, solid shapes.

How does the plastic injection molding machine work?

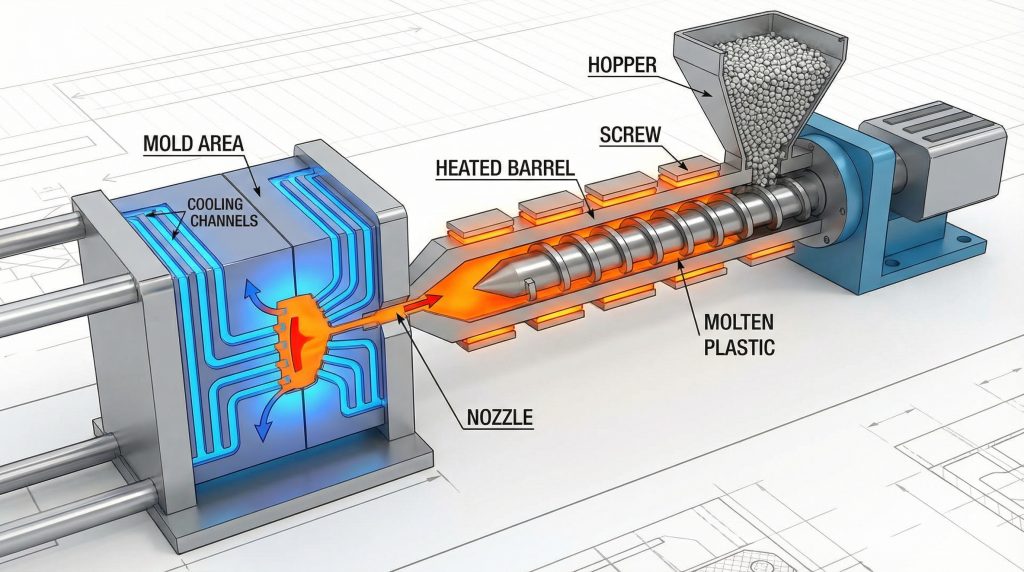

The plastic injection molding machine works by heating up plastic beads and squeezing them into a cold metal mold. The machine is very big and heavy because it has to use a lot of power. It has a heater to melt the plastic and a motor to push it forward. Once the plastic is inside the mold, it stays there for a few seconds to get hard.

What happens inside the heater?

Inside the machine, there is a long tube with a spinning screw that gets very hot.

Here is the deal:

- The screw turns and moves the plastic beads forward.

- The heat turns the hard beads into a thick liquid.

- It looks like hot honey before it goes into the mold.

This hot liquid is what allows us to create such detailed and pretty shapes!

How does the part come out?

After the plastic fills the mold, the machine uses cold water to cool it down instantly.

Wait for it:

- The metal mold opens up like a book.

- Small pins push the finished plastic part out.

- The part falls into a box, and the mold closes again.

This happens over and over again without the machine ever getting tired.

| Machine Part | What It Does | |

|---|---|---|

| Hopper | Holds the dry plastic beads | |

| Screw | Melts and pushes the plastic | |

| Pins | Pushes the finished part out |

Using a machine like this is the secret to making millions of toys and tools.

Key Takeaway: The machine acts like a giant heater and press to turn beads into finished products.

Which materials are used for plastic injection molding?

There are many different types of Plastic injection molding materials that we use to make products soft, hard, or clear. Some plastics are very tough and can be used for car engines. Other plastics are very soft and feel like a rubber band in your hand. We help you choose the best “recipe” for your project so it works exactly right.

Can we use different colors?

We can make your parts in any color of the rainbow by mixing in special dyes.

You might be wondering:

- The color is mixed deep into the plastic beads.

- It will never scratch off or fade away.

- We can even make parts that shine in the dark!

This makes your products look beautiful and professional for your customers.

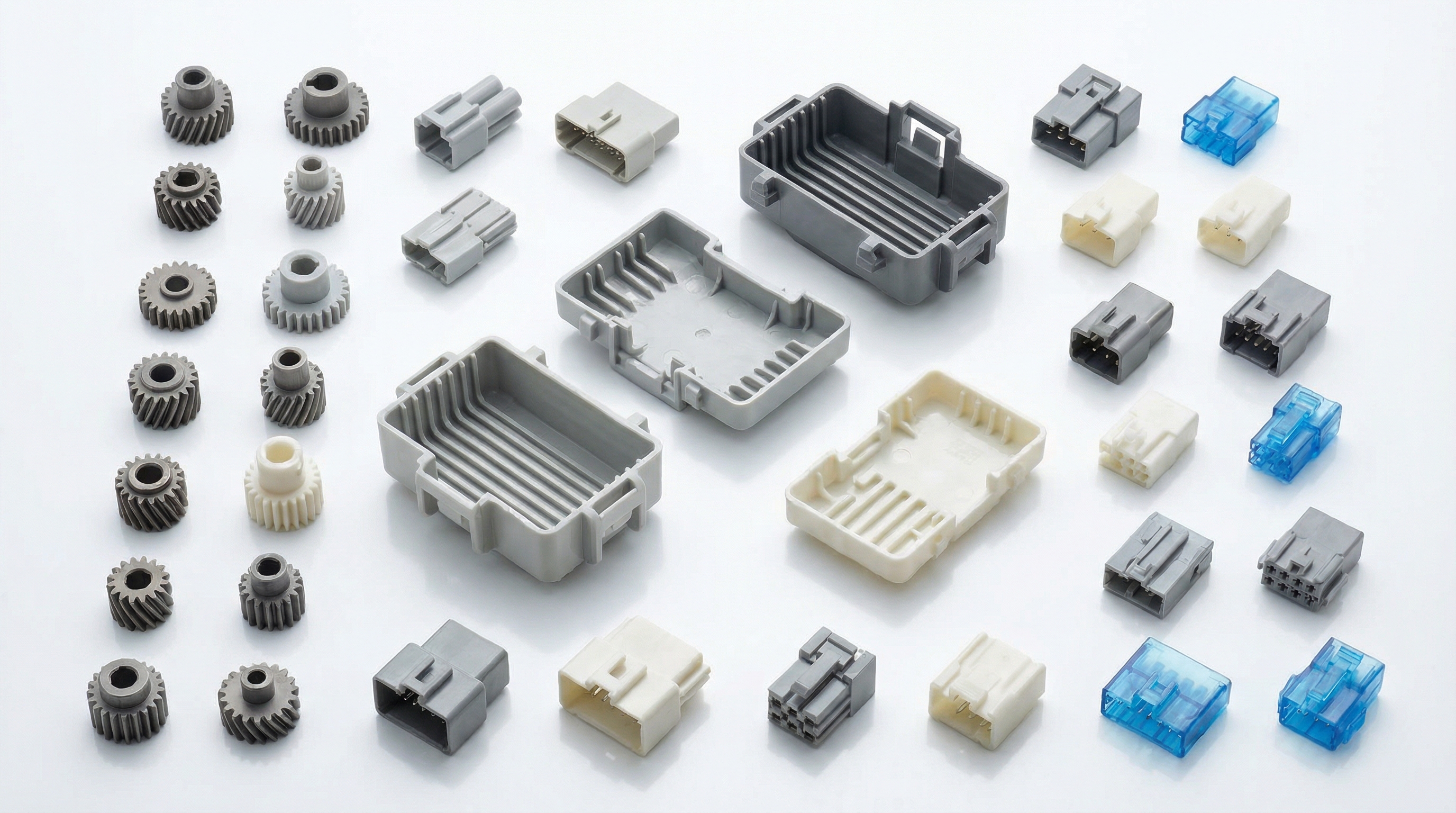

Are some plastics stronger than others?

Yes, some plastics are designed to be as strong as metal but much lighter.

The best part is:

- ABS plastic is great for toys and hard cases.

- Nylon is very slippery and works well for gears.

- Polycarbonate is clear and very hard to break.

We make sure the material fits the job so your product never fails.

| Material | Best Use | |

|---|---|---|

| ABS | Toys and Electronics | |

| Nylon | Moving parts and Gears | |

| PC | Clear lenses and Helmets |

Choosing the right plastic is the most important step to making a great product.

Key Takeaway: Different plastics have special powers, and we pick the right one for your specific needs.

How is a plastic injection molding mold made?

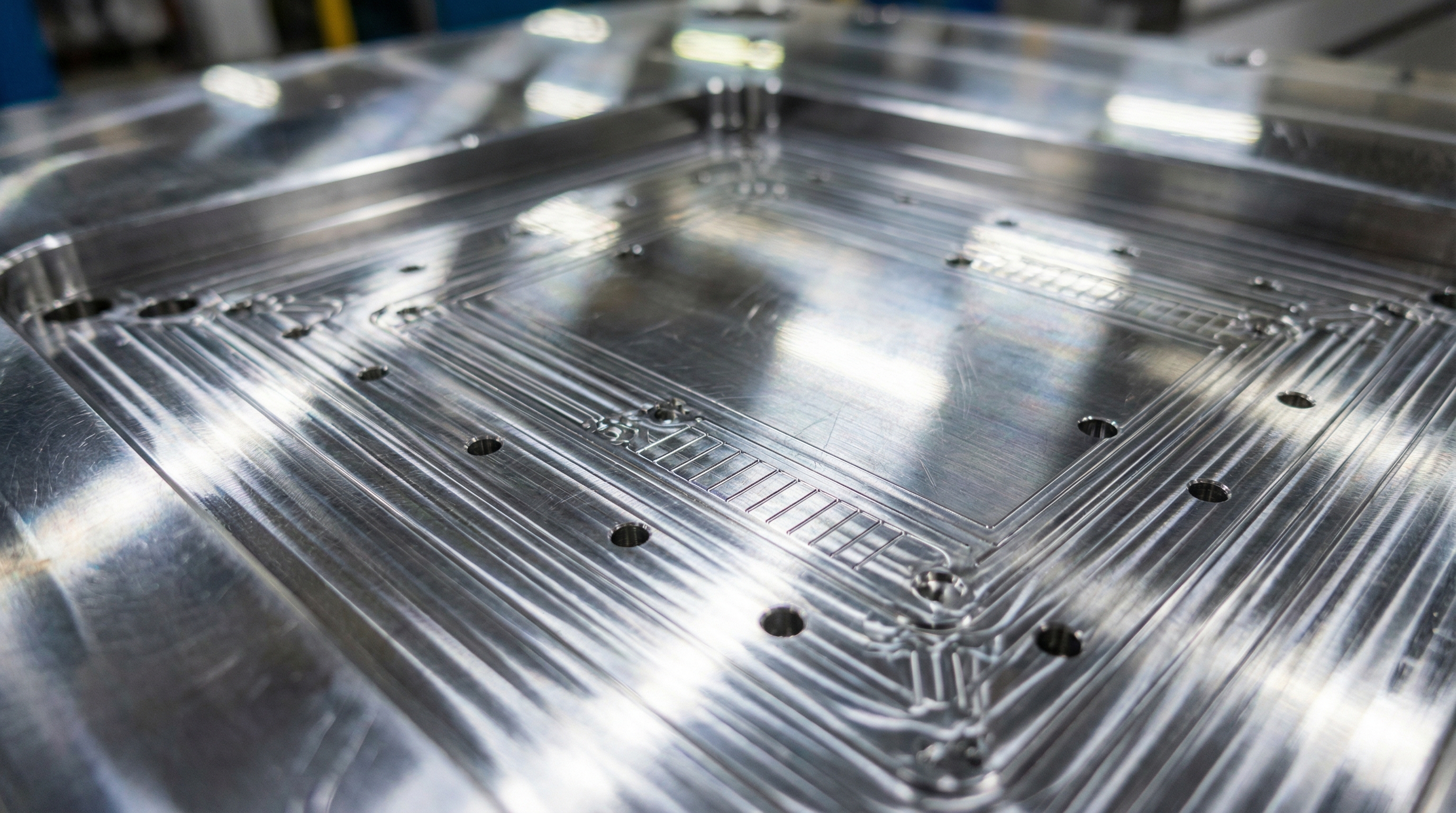

A plastic injection molding mold is made by carving a shape into a heavy block of solid steel. We use special robotic drills that are very precise to cut the metal. The mold has two halves that fit together perfectly with no gaps. If the mold is not perfect, the plastic parts will not look right.

Why do we use steel?

We use steel because it is strong enough to be used millions of times without breaking.

Here is the deal:

- The plastic is pushed in with a lot of pressure.

- Steel doesn’t bend or lose its shape.

- It stays smooth so the parts look shiny.

This means your mold will last for many years and make many parts!

How do we get the shape right?

We use computers to draw the part and tell the drills exactly where to cut.

Look:

- The drills can cut details thinner than a hair.

- We polish the inside until it looks like a mirror.

- We add tiny tunnels for water to keep it cool.

Our European Quality standards mean every mold is built to be the best in the world.

| Mold Part | Purpose | |

|---|---|---|

| Cavity | The hole that shapes the plastic | |

| Core | The part that makes the inside hollow | |

| Cooling Lines | Tunnels for water to cool the mold |

A high-quality steel mold is the foundation of every great plastic product.

Key Takeaway: Molds are precision steel tools that define the shape and quality of every part.

Why is plastic injection molding used for car parts?

We use automotive injection molding to make cars safer, lighter, and much more beautiful for you. Most of the things you touch inside a car, like the dashboard or buttons, are made this way. Plastic is better than metal for these parts because it doesn’t rust. It also helps the car use less gas because it is not heavy.

Does it make cars safer?

Plastic parts can absorb energy during a crash to protect the people inside the car.

But wait, there’s more:

- Bumpers can bend and bounce back.

- Interior parts don’t have sharp metal edges.

- It holds the glass and wires safely in place.

This technology helps keep you and your family safe while you are driving!

Can we make complex car shapes?

Yes, we can make very complicated shapes that would be impossible with metal.

Believe it or not:

- We can mold a whole dashboard as one big piece.

- We can add textures that look and feel like leather.

- Everything fits together perfectly with no squeaky sounds.

Our Factory Direct prices help car makers build better vehicles for less money.

| Car Part | Material Used | |

|---|---|---|

| Dashboard | Tough, heat-resistant plastic | |

| Door Handle | Strong, reinforced plastic | |

| Light Cover | Clear, see-through plastic |

Plastic parts are the reason modern cars are so comfortable and quiet.

Key Takeaway: Cars use plastic to be lighter and safer for everyone on the road.

Can plastic injection molding create home appliances?

We use home appliance furniture molds to create the tools you use in your kitchen and laundry room every day. Your coffee maker, your vacuum cleaner, and even your refrigerator drawers are made from plastic. These parts need to be very clean and easy to wash. Plastic is the perfect choice because water and soap do not hurt it.

Why is it good for the kitchen?

Plastic doesn’t get hot like metal, so it is safe to touch on your toaster or kettle.

Here is the deal:

- Food-safe plastics keep your meals healthy.

- Smooth surfaces are very easy to wipe clean.

- Transparent plastic lets you see what is in the fridge.

This makes your life at home much easier and your kitchen look very modern!

Is it strong enough for big machines?

Our appliance parts are built to be very tough so they can handle a lot of work.

The best part is:

- Washing machine parts can handle lots of water.

- Vacuum bodies don’t crack when they hit the wall.

- Buttons can be pressed thousands of times.

We ensure every part meets European Quality levels so your appliances last for years.

| Appliance | Plastic Part | |

|---|---|---|

| Refrigerator | Bins and door shelves | |

| Blender | The base and the buttons | |

| Washing Machine | The control panel and soap tray |

Home appliances rely on plastic to be lightweight, clean, and very durable.

Key Takeaway: Plastic makes our home tools easier to use and much easier to keep clean.

How does plastic injection molding help industrial machines?

We use industrial automation molds to make parts that help big factory robots and machines work correctly. These machines often have to move very fast or carry heavy things. We make special plastic gears and covers that protect the machines from dust and heat. This keeps the factory running smoothly without any breaks.

Do plastic gears work well?

Plastic gears are much quieter than metal gears and they never need messy oil.

Wait for it:

- They don’t rust even in wet factories.

- They are much lighter and move faster.

- They are cheaper to replace if they wear out.

This helps factories save a lot of money and keep the noise down!

How do we protect electrical wires?

We make plastic boxes and clips that keep wires safe so nobody gets an electric shock.

Look:

- Plastic stops electricity from moving to the metal.

- It keeps the wires organized and dry.

- The covers are very hard to break or melt.

Our Factory Direct service means you get these important parts quickly and easily.

| Industrial Part | Main Benefit | |

|---|---|---|

| Plastic Gear | Quiet and no oil needed | |

| Wire Connector | Keeps electricity safe | |

| Safety Shield | Protects workers from moving parts |

Industrial plastic parts are essential for keeping our modern factories safe and efficient.

Key Takeaway: Industry uses plastic to make machines quieter, safer, and much more reliable.

Why is quality so important in plastic injection molding?

In plastic injection molding, quality is the most important thing because every part must fit perfectly. If a part is too big by even a tiny amount, it might not work in your product. We use high-tech cameras and lasers to check every single piece we make. This ensures that you only get the best parts for your business.

How do we find mistakes?

We have special robots and experts who look at every part for any tiny problems.

But wait, there’s more:

- We check the color to make sure it is right.

- We measure the size with very smart tools.

- We test the strength to make sure it won’t break.

If a part is not perfect, we don’t send it to you because we care about your success!

What is the HST standard?

Our European Quality standard means we follow the same rules as the best factories in the world.

Believe it or not:

- We check our machines every single hour.

- We use only the best plastic beads.

- Our team has over 10 years of experience.

This gives you peace of mind knowing your products are in good hands.

| Quality Test | What We Check | |

|---|---|---|

| Measurement | Is the size exactly right? | |

| Stress Test | Does it break under pressure? | |

| Visual Check | Does it look beautiful and smooth? |

High quality means your customers will be happy and your brand will be famous.

Key Takeaway: Great quality ensures every part works perfectly and makes your customers happy.

What makes HST Technology the best for plastic injection molding?

Plastic injection molding at HST Technology is special because we are a direct factory with 10+ years of experience. This means you talk to the people who actually make your parts, not a middleman. We provide European Quality at a price that fits your budget perfectly. We treat every customer like a partner and help you every step of the way.

Do you get better prices?

Yes, because we are Factory Direct, you don’t have to pay extra fees to other companies.

Here is the deal:

- You save money on every single part.

- We control the quality from start to finish.

- We can ship your parts to you much faster.

This helps your business grow faster because you have more money to spend on new ideas!

Can you trust our team?

Our team is very friendly and we have helped many customers in Europe and America.

The best part is:

- We answer your emails and calls very quickly.

- We give you expert advice on your designs.

- We show you photos of your project every week.

We want you to feel excited and happy when you work with us!

| Why Choose HST? | Benefit for You | |

|---|---|---|

| Direct Factory | Lower prices and faster speed | |

| 10+ Years | We know how to solve problems | |

| European Quality | Your parts will be world-class |

HST Technology is the best choice for anyone who wants perfect plastic parts and a friendly partner.

Key Takeaway: HST Technology combines expert experience with direct factory prices to help you succeed.

How can you start your own plastic injection molding project?

Starting a plastic injection molding project is very easy when you work with the experts at HST Technology. All you need is a drawing or a 3D model of the part you want to make. You send it to us, and we will tell you the best way to turn it into a real product. We help you with the design, the mold, and the final parts.

What is the first step?

The first step is sending us your idea so we can give you a free price quote.

You might be wondering:

- Do I need a perfect drawing? Not always!

- Can I pick any color? Yes, you can!

- Is it expensive? We will find the best price for you.

We make the starting process very simple so you don’t feel stressed or confused.

When do you get your parts?

We build your custom mold and send you the first samples to check in just a few weeks.

Look:

- You get to hold the real part in your hand.

- You tell us if you want any changes.

- Once you are happy, we make thousands more!

It is like magic seeing your computer drawing turn into a real object you can hold.

| Step | What We Do | |

|---|---|---|

| 1. Design | We look at your 3D model | |

| 2. Tooling | We carve your steel mold | |

| 3. Sampling | We send you the first parts |

Starting your project today is the best way to bring your big idea to life!

Key Takeaway: Starting is easy—just send us your idea and we will handle all the hard work.

Frequently Asked Questions

Can I make any shape I want?

Yes, you can make almost any shape with a mold, but simple shapes are usually cheaper. If your shape is very complex, our engineers will help you adjust it so it comes out of the mold perfectly every time.

What is the best plastic for my project?

It depends on what you need! If you want something strong, ABS is great, but if you want something clear, Polycarbonate is better. We will listen to your needs and suggest the perfect plastic “recipe” for you.

How many parts do I have to buy?

Since we are a direct factory, we can help you with both small and large orders. Most people start with a few thousand parts to get the best price, but we can talk about what works best for your specific business.

How long does the mold last?

Our high-quality steel molds are built to last for hundreds of thousands of “shots.” This means you can keep making parts for many years without ever needing to buy a new mold.

How do I know if the parts will fit?

We use very precise machines to measure every part down to a tiny fraction of a millimeter. We also send you samples to test yourself before we make the big batch, so you know they fit perfectly.

Conclusion

Plastic injection molding is the most amazing way to turn your creative ideas into real, high-quality products. It allows us to make thousands of perfect items that are strong, beautiful, and very affordable for everyone. From the car you drive to the gadgets in your kitchen, this technology is everywhere, making our lives better every single day. By using precision steel molds and high-tech machines, we ensure that every piece is a perfect match for your needs.

If you are ready to start your journey and make something great, the team at HST Technology is waiting to help you. We provide the expert skills, Factory Direct prices, and European Quality you need to win in your market. We promise to make the process easy, fast, and fun for you from the very first day. Please contact us today to get your free quote and see how we can bring your best ideas to life with perfect precision!