Plastic Injection Molding: Making Perfect Parts Every Time

1. Making Many Parts is Hard Work

Imagine you need to make 10,000 plastic toy cars. If you tried to make them one by one by hand, it would take forever! Even worse, they might all look a little different. It is very hard and costs a lot of money to make many plastic things quickly. If you have a big project, you might worry about how much it will cost or if the parts will be strong enough.

This is why many people feel stuck. But there is a better way! HST Technology makes this easy. We use a special method called plastic injection molding to make thousands of perfect parts very fast. We take the stress away so you can get your products made the right way.

2. What is Plastic Injection Molding?

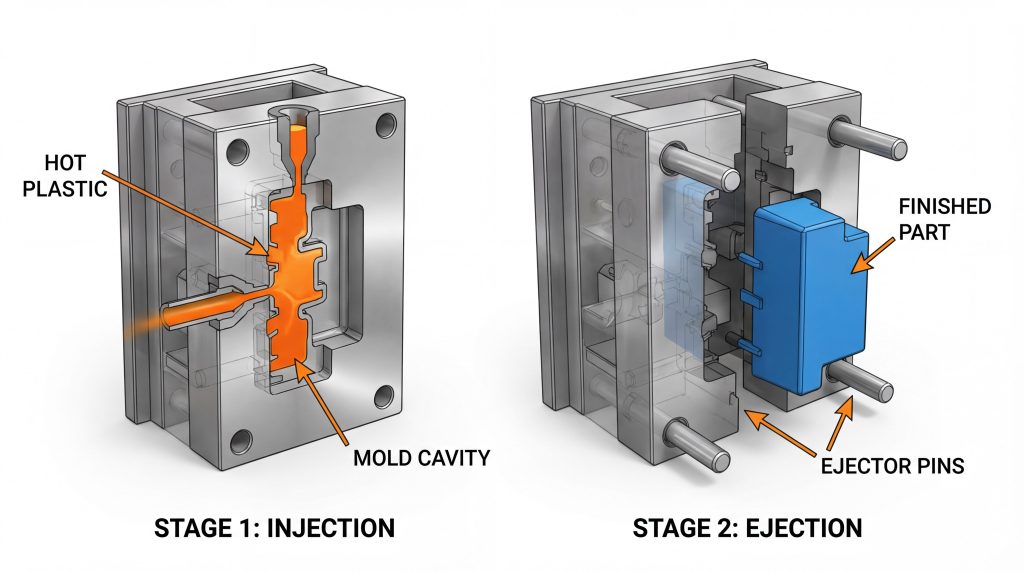

Plastic injection molding is a way to make shapes out of plastic. Think of it like making ice cubes. You pour water into a tray, freeze it, and out comes an ice cube in the shape of the tray.

In our factory, we use melted plastic instead of water. We push the hot, liquid plastic into a strong metal mold. Once the plastic cools down, it becomes hard. When we open the mold, a perfect part pops out! You can see all the different things we make on our products page .

3. How the Big Machines Work

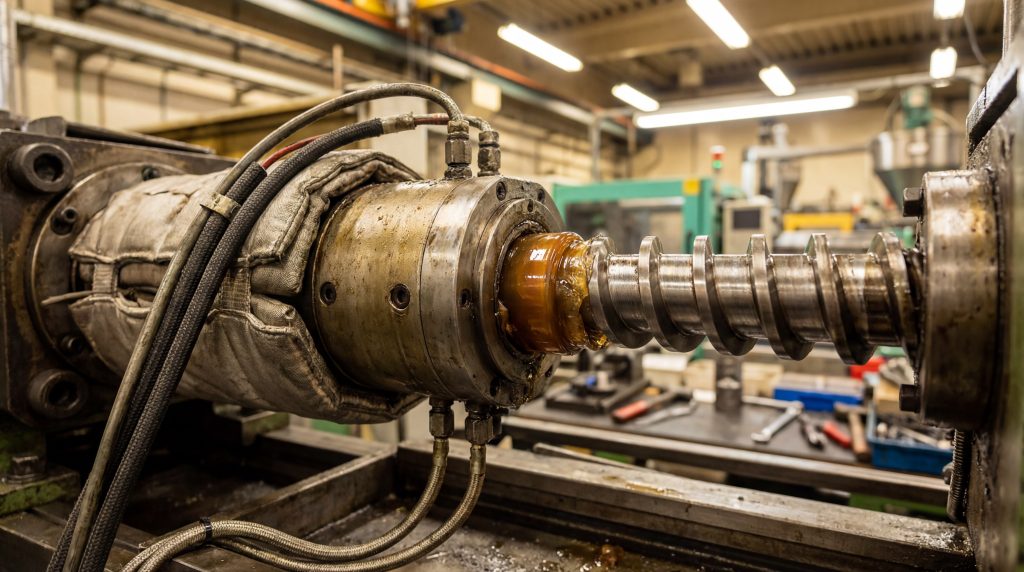

The machines we use are very big and strong. First, we put tiny plastic beads into a hopper. The machine heats these beads until they melt into a gooey liquid. Then, a large screw pushes the melted plastic into the mold with a lot of force.

We keep the plastic under pressure so it fills every tiny corner of the mold. After a few seconds, the plastic is cool and hard. The machine opens up, the part falls out, and it starts all over again! It is a very fast cycle that happens over and over.

4. The Secret is in the Mold

The most important part of the process is the mold. The mold is a block of metal with a hollow space inside that is shaped exactly like the part you want. At HST, we are experts at making these molds.

We make molds that are very precise. This means they are accurate down to a tiny fraction of a millimeter (±0.02mm). Because our molds are so good, every part that comes out of them is exactly the same as the first one.

5. Things We Make Every Day

You can use injection molding to make almost anything! At HST, we help many different industries. We make parts for:

- Cars: Like door handles and sensor covers.

- Homes: Like parts for your fridge or furniture.

- Electronics: Like cases for phones or computers.

- Tools: Strong parts for big machines.

No matter what you need to make, we can help you find the right plastic and the right design.

6. Saving Time and Money

When you need a lot of parts, injection molding is the best way to save money. Even though the metal mold costs money to build at first, making each part after that is very cheap.

Because the machines work so fast, we can finish big orders in just a few weeks. At HST, we give you weekly updates with photos so you can see your parts being made. We make sure everything stays on time so you don’t have to wait.

7. Why Choose a Direct Factory?

HST is a direct factory in China. This means there is no “middleman” or extra person between us. You talk directly to the people making your parts!

This is great because it means:

- Lower Prices: You don’t have to pay extra fees to a trader.

- Better Talk: You can talk directly to our engineers about your design.

- Better Quality: We watch every step of the work ourselves.

8. High Quality for Everyone

We have been sending parts to Europe and other places for over 10 years. We know that parts need to be strong and look good. We test every part to make sure it is the right size.

We use special tools like a CMM (Coordinate Measuring Machine) to check the math of the parts. If a part isn’t perfect, we don’t send it. We want you to be happy with every single box we ship to you.

A quality control worker using a measuring tool to check the size of a plastic part very carefully.

9. Choosing the Best Plastic

Not all plastic is the same! Some plastic is soft and bendy, while other plastic is as hard as a rock. Some can handle heat, and others come in bright colors.

Our team helps you pick the best material for your job. Whether you need something that won’t burn or something that looks beautiful, we have the right plastic beads ready to go.

A hand holding several different types of small, colorful plastic beads used for molding.

10. Start Your Project Today!

Ready to turn your idea into a real plastic part? It is very easy to get started with HST. All you need to do is send us a drawing or a sample of what you want to make.

Our engineers will look at your design and give you a price quote in just 24 hours. We will help you every step of the way, from the first drawing to the final delivery. Contact us today to get a free quote!

A “Get a Quote” button next to a picture of a finished high-quality plastic product.

Frequently Asked Questions

How long does it take to make a mold?It usually takes about 4 to 6 weeks to build a high-quality metal mold. Once the mold is finished, we can make thousands of parts very quickly!

Can I make parts in different colors?Yes! We can mix special colors into the plastic beads to make your parts almost any color you want.

Is injection molding good for small orders?It is usually best for orders of 500 parts or more. Because the mold takes time to make, it works best when you need to make many items.

What information do you need for a quote?It is best to send us a 3D drawing (like a STEP file) and tell us how many parts you need. If you aren’t sure, just ask us for help!