Have you ever wondered how someone can make thousands of plastic toy cars that look exactly the same? It is very hard to make many things by hand because they usually end up looking a little different, which can be a big problem. This is where we run into trouble when we need a lot of tools or toys fast. Plastic injection molding from HST-Tech is the solution because it uses special metal tools to make perfect plastic parts every single time.

Key Highlights

Key Takeaways

- Fast: We can make thousands of parts very quickly.

- Exact: Every part looks just like the one before it.

- Strong: We can use tough plastic for car parts and tools.

- Easy: Once the mold is ready, making parts is simple and cheap.

What is plastic injection molding?

Plastic injection molding is a smart way to make plastic things by melting plastic and pushing it into a metal shape. It is the most common way to make objects like bottle caps, Lego bricks, and even parts for your car.

How does this process help you?

This process is great because it makes parts very quickly and keeps the cost low for big orders. You can create very complex shapes that other machines just cannot handle.

Think about this:

- It makes thousands of parts in just a few hours.

- You can choose any color you want for your parts.

- It uses almost all the plastic so there is very little waste.

Best of all, once the metal tool is made, the price for each part becomes very small.

Key Takeaway: Plastic injection molding is the best choice for making huge numbers of identical, high-quality plastic items quickly.

How does the injection machine work?

A plastic injection molding machine works by heating up plastic beads until they turn into a liquid and then squishing them into a cold mold. The machine uses a giant screw that turns and pushes the hot plastic forward into the metal tool.

Where does the liquid plastic go?

The liquid plastic travels through a small hole and fills up all the empty space inside the metal mold. After the plastic cools down and turns hard, the machine opens up and the finished part drops out.

Believe it or not:

- The machine stays closed with tons of heavy pressure.

- The screw works like a giant heater and a syringe.

- Making one part can take less than 30 seconds.

It is like using a giant, high-tech waffle iron to make plastic shapes!

Key Takeaway: The machine is a powerful tool that melts, moves, and shapes plastic with incredible speed and force.

Which materials can we use?

Plastic injection molding can use many different types of plastic, ranging from soft and bendy to very hard and strong. We choose the material based on what you want to make, such as a soft phone case or a hard helmet.

Is all plastic the same?

No, because different plastics have special “superpowers” like being waterproof or being able to stay strong in a car crash. Some plastics are even mixed with glass to make them as strong as metal.

Here are some common types:

- ABS: Very tough and used for toys and computer cases.

- PP: Great for kitchen bowls and flexible lids.

- PC: Clear and strong like the windows on an airplane.

You have so many choices to find the perfect match for your big project.

| Material | Best Use |

|---|---|

| ABS | Toys and Electronics |

| PP | Kitchenware |

| PC | Clear Lenses |

Selecting the right material ensures your product lasts a long time and works correctly.

Key Takeaway: You can pick from thousands of plastic recipes to make sure your part is as strong or flexible as you need.

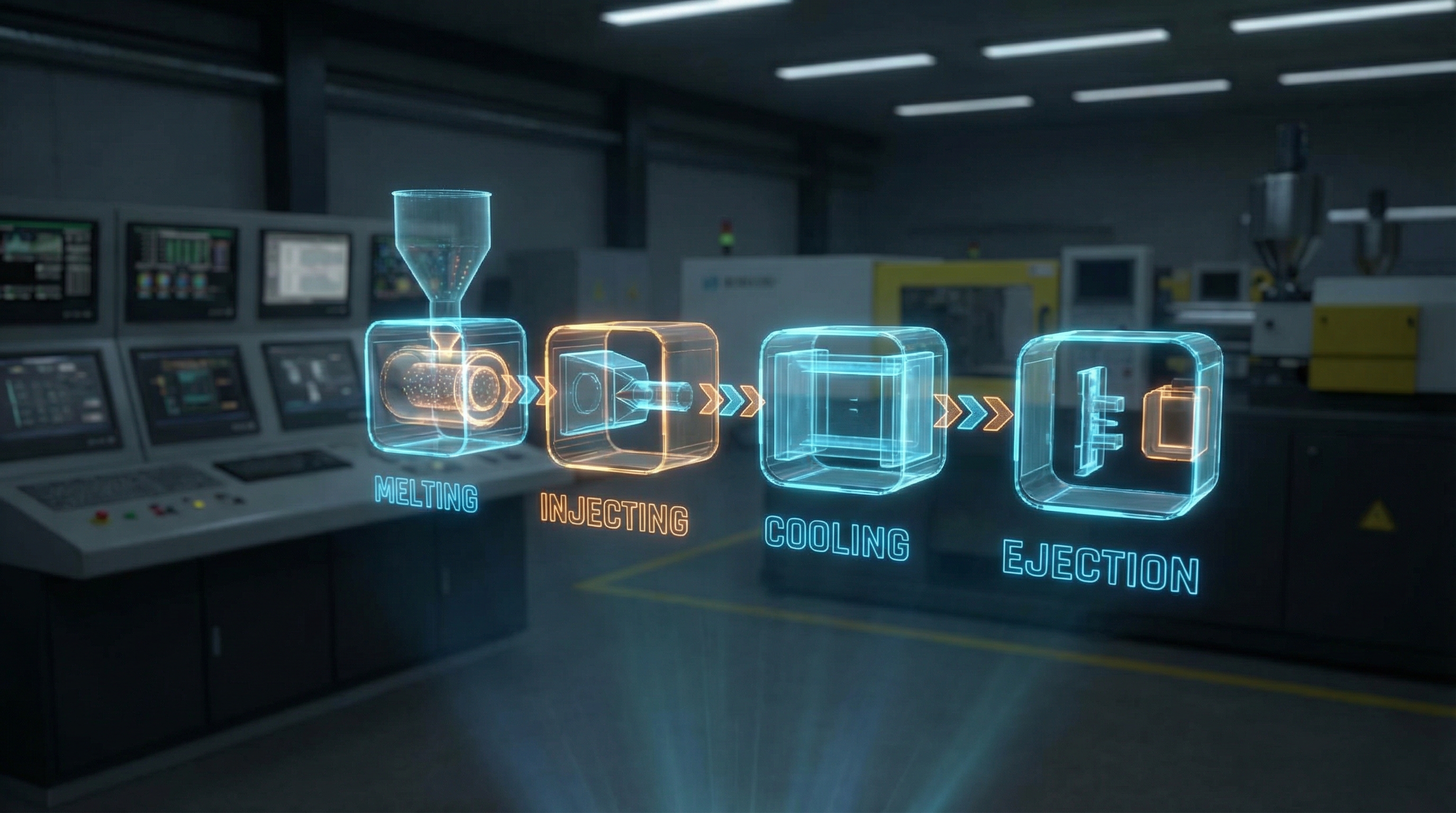

What is the molding process?

The plastic injection molding process follows a set of steps to turn raw plastic beads into a finished product. It starts with melting the beads, followed by injecting them, cooling the part, and finally pushing the part out.

What are the main steps?

First, the metal mold closes very tightly, and then the hot liquid plastic fills the empty space inside. Once the plastic is inside, we must wait a few seconds for it to cool down and become solid.

But wait, there’s more:

- Cooling is the part of the cycle that takes the most time.

- We keep the pressure high so the part doesn’t shrink.

- Tiny metal pins push the finished part out at the end.

This cycle repeats over and over, day and night, to make all your products.

| Process Step | What Happens |

|---|---|

| Injection | Plastic fills the mold |

| Cooling | Part becomes solid |

| Ejection | Part is pushed out |

This cycle ensures that every part is made with the same timing and temperature.

Key Takeaway: The process is a repetitive loop that ensures every single part is cooled and shaped the exact same way.

Why is mold design vital?

The design of the plastic injection molding tool is the most important part because it decides if your part will look good. A good mold has water channels inside to help the plastic get cold and hard very quickly.

How do we make the mold?

We use very strong steel and cut the shape using precise machines that are controlled by computers. The mold must be very strong to handle the heavy pressure from the injection machine.

Here is the secret:

- Slanted sides help the part slide out without getting stuck.

- Small vents let air out so the plastic can get in.

- Shiny polishing makes the finished part look smooth.

A well-designed mold can make over a million parts before it gets tired!

Key Takeaway: The mold is the heart of the process; if the design is perfect, the parts will be perfect too.

What are the main advantages?

Plastic injection molding is the best way to make things because it gives you the best speed, cost, and quality. Once you have your mold, you can make millions of parts with very little work from people.

Why should you choose this method?

It is the fastest way to grow your business from a small idea to a huge product sold everywhere. You can even make several different parts at the same time using one big mold.

The best part is:

- It is good for the Earth because we can reuse extra plastic.

- It allows for very thin walls, which saves you money.

- The parts are ready to use the second they fall out of the machine.

There is no better way to make high-quality plastic items at a very large scale.

| Advantage | Business Impact |

|---|---|

| Low Labor | Lower cost for each part |

| Consistency | No difference between parts |

| High Speed | Meets high market demand |

These advantages make it the go-to solution for global manufacturing companies.

Key Takeaway: Choosing injection molding allows you to scale up production while keeping your quality high and costs low.

Where are these parts used?

Plastic injection molding parts are everywhere, from the dash in your car to the tools doctors use in hospitals. They are used in almost every business because they are light and they do not break easily.

Are they in your car?

Yes, modern cars use hundreds of molded parts to make them lighter so they use less gas. Parts like door handles, vents, and even parts under the hood are all made this way.

Think about these places:

- Medical: Clear tubes and safety tools.

- Home: Toothbrushes and remote controls.

- Industrial: Strong gears for big machines.

You probably touch at least fifty molded parts before you even finish your breakfast!

Key Takeaway: From cars to medicine, molded plastic parts make our modern life safer, easier, and more affordable.

What about part precision?

Precision in plastic injection molding means making parts that are exactly the right size, even down to a tiny dot. This is very important for parts that have to fit together perfectly, like pieces of a puzzle.

Does every tiny detail matter?

Yes, because even a tiny mistake can make a part leak or stop a machine from working. We use high-tech sensors to make sure the pressure is perfect for every single part we make.

Here is how we do it:

- We use the best precision standards for our tools.

- We check the heat every second to keep it the same.

- We use robots to pick up the parts very gently.

When the precision is high, your parts will always fit and work the way they should.

| Precision Metric | Importance |

|---|---|

| Tolerance | Parts fit together perfectly |

| Finish | Parts feel smooth and nice |

| Weight | Every part weighs the same |

High precision reduces waste and ensures that your customers are always happy with the quality.

Key Takeaway: Great molding isn’t just about making parts; it is about making parts that are exactly right every single time.

How do we check quality?

Checking the quality of plastic injection molding parts means we make sure no bad parts ever leave our building. We use cameras and smart people to look for tiny cracks or the wrong colors.

Are the parts always perfect?

We make sure they are by comparing them to a “master part” that is the perfect example. If a part is too heavy or has a bubble, the machine knows and we fix it right away.

Watch for these tests:

- Strength tests: We try to see if the part can break.

- Heat tests: We see if the part melts when it gets hot.

- Visual tests: We look for any marks or spots.

Quality control is our promise that your project will be a big success.

Key Takeaway: We use strict testing and high-tech tools to guarantee that every part meets your high standards.

How do we start a project?

Starting a project is easy when you have a partner who knows how to design and build things correctly. We help you pick the right plastic and design the best mold for what you need to make.

Can we work together on your idea?

We love helping people turn their drawings into real products that they can sell in stores. Our team looks at your design and finds the best way to make it at the lowest price.

Here is how we start:

- You send us your drawing or design.

- We give you a price for the project.

- We build the mold and send you samples to check.

Once you like the samples, we start making all the parts for you!

| Project Step | Your Role | Our Role |

|---|---|---|

| Start | Share your idea | Give expert advice |

| Building | Check the design | Build the metal tool |

| Making | Give the okay | Make and ship parts |

Following these simple steps takes the stress out of making your new product.

Key Takeaway: A clear plan and a helpful partner make the journey from idea to finished product smooth and successful.

Conclusion

We have learned how injection molding turns tiny plastic beads into the useful things we use every day. By solving the problem of making many things at once with speed and precision, this process helps everyone. Whether you are building a new part for a car or a simple tool for the house, HST-Tech is here to help you succeed. We provide the high-quality molds and expert help you need to be the best.

Ready to bring your vision to life? Contact us today and let our precision engineering team help you create perfect parts. We want to be your most reliable partner for making great things!

FAQ

How do I know if my design is ready for molding?

Can I change the color of my parts later? Yes! You can easily change the color by changing the dye we mix with the plastic. This lets you have many different colors of the same part.

How do I know if I need a steel or aluminum mold?

Can I use any type of plastic for my project?

What’s the best way to lower my part cost? The best way is to make a lot of parts at the same time. When you make a big order, each part becomes much cheaper to build.

Ready to start your project?

Our expert team is ready to help you turn your ideas into reality with high-quality plastic molding.