Automotive Mold Solutions Built for Precision & Production Stability

Thousands of pre-deformation tooling cases, more than 10 years experience deep digging. Excellent Team+Advanced Machine+Rich Experience=Top Quality Mold. HST will be your best choice for high gloss molds!

- Advanced mold flow analysis ensures first-shot success

- Direct engineering support from design through production

Why Automotive Molds Demand More Than Standard Manufacturing

Automotive injection molding presents unique complexities that separate routine tooling from production-grade solutions. Understanding these challenges is critical to avoiding costly failures during mass production.

Extreme Precision Requirements

Automotive parts demand tolerances within ±0.05mm for proper assembly and functionality. This level of accuracy ensures seamless fitment across thousands of production units, preventing assembly line rejections and costly rework that can derail your manufacturing schedule.

Long-Term Production Stability

Molds must maintain consistent output through 500,000+ cycles without degradation. Our strategic material selection and optimized cooling design ensure your investment delivers reliable performance throughout its intended lifespan, eliminating unexpected production halts.

Complex Material Performance

Automotive-grade resins require precise processing parameters. We optimize gate design and thermal management for glass-filled materials, engineering plastics, and multi-material assemblies, ensuring each part meets mechanical strength and cosmetic requirements without warping or defects.

Ready to eliminate these risks from your automotive mold project?

Risk-Reduction Process for Automotive Mold Development

Our systematic approach eliminates guesswork and prevents costly rework by addressing potential failures before they reach your production floor. Each validation stage builds confidence through proven engineering methods.

DFM Analysis

Engineers identify moldability issues, wall thickness problems, and draft angles before finalizing your design.

Mold Engineering

3D design integrates cooling optimization and ejection strategy using automotive-standard CAD/CAM systems.

Flow Simulation

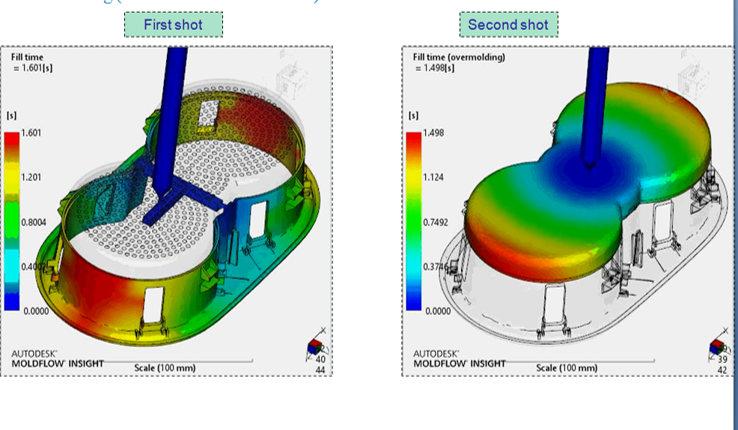

Moldflow predicts filling patterns and warpage risks, allowing virtual testing before steel cutting begins.

Trial Optimization

First article inspection validates accuracy while process parameters are refined for optimal quality.

Production Control

Statistical monitoring ensures long-term stability throughout high-volume manufacturing runs.

Experience the confidence that comes from systematic risk elimination.

Real-World Success Stories

From concept to mass production, our automotive mold solutions deliver measurable improvements in quality, efficiency, and cost control. Each project demonstrates our commitment to engineering excellence and production stability.

Interior Parts

Interior Parts

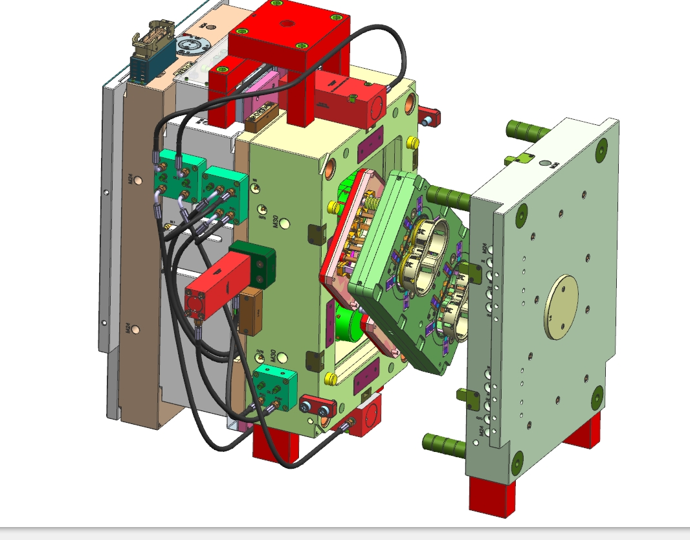

Cup Holder in 2 shot mold

From Moldflow Analysis to sucessful molding part.European OEM required Class A surface finish on a complex console assembly with tight assembly tolerances. Previous supplier experienced 30% rejection rate due to sink marks and warpage issues.

Implemented conformal cooling channels and optimized gate locations through Moldflow analysis. Redesigned ejection system to prevent surface defects while maintaining dimensional accuracy.

Structural Parts

Structural Parts

Glass-Filled PA66 Mounting Bracket

Safety-critical bracket required validated mechanical properties with fiber orientation control. Part geometry created risk of weld lines in high-stress areas that could compromise structural integrity.

Strategic gate placement eliminated weld lines from critical stress zones. Material flow simulation validated fiber alignment. Complete mechanical testing confirmed tensile strength exceeded OEM specifications by 15%.

Exterior Systems

Exterior Systems

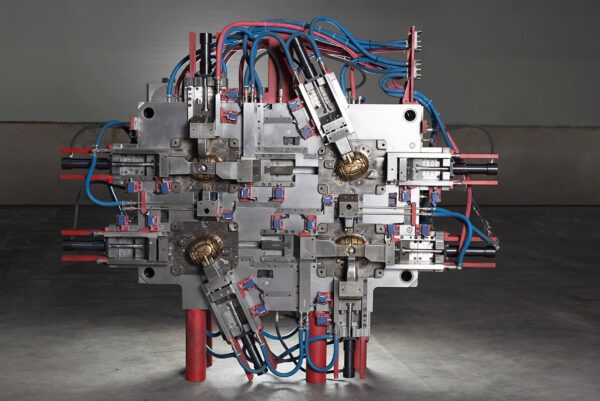

Multi-Cavity Automotive Mold

Asian automotive supplier needed 4-cavity mold producing identical parts for high-volume production. Previous tooling showed 0.15mm variation between cavities, causing assembly problems and increased sorting costs.

Balanced runner system with hot runner technology eliminated cavity-to-cavity variation. Individual cavity temperature control and optimized cooling maintained uniform part dimensions across all positions throughout production runs.

Your project deserves the same engineering attention and proven results.

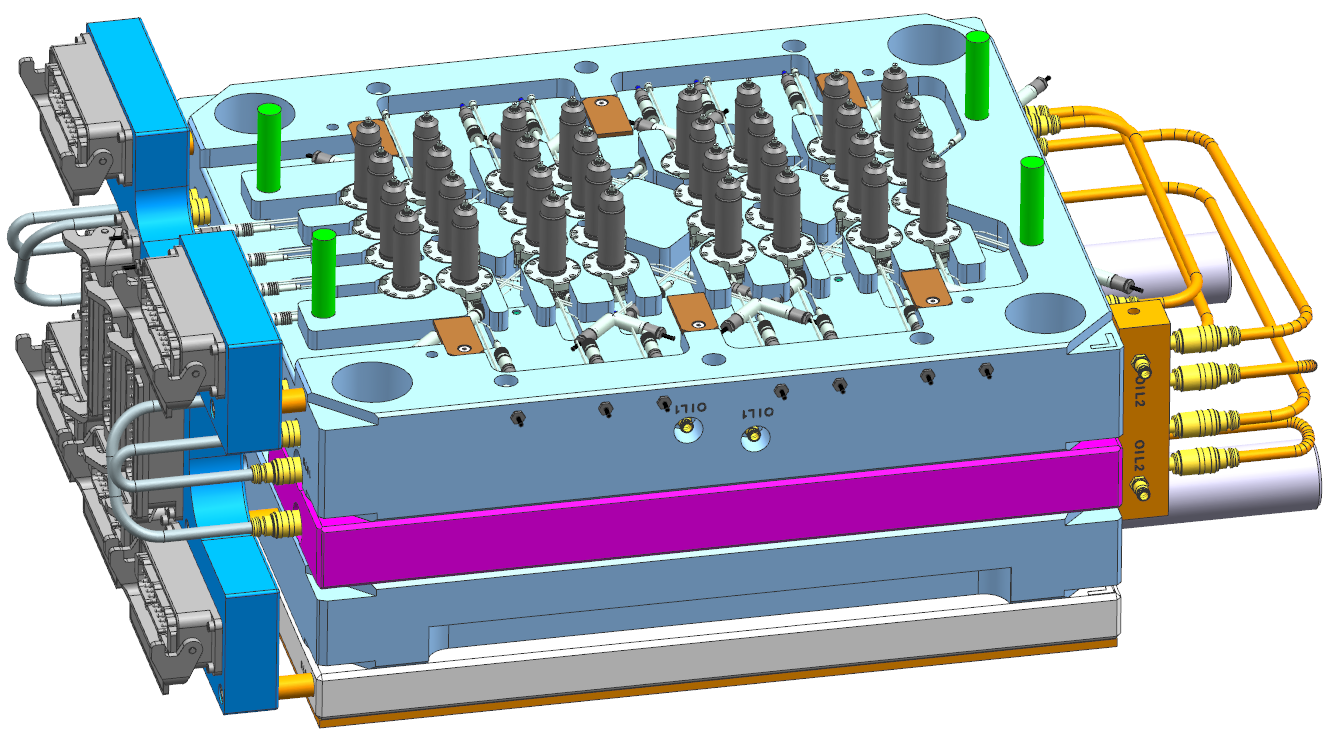

Advanced Engineering & Manufacturing Capabilities

Our technical infrastructure combines cutting-edge simulation software, precision manufacturing equipment, and deep automotive industry expertise to deliver molds that perform reliably from first shot through 500,000+ production cycles.

Moldflow Analysis

Autodesk Moldflow Insight simulates injection pressure, temperature distribution, and material behavior to eliminate defects before mold fabrication.

Advanced CAD/CAM

NX and Mastercam systems enable complex 5-axis toolpaths for intricate geometries, ensuring precise cavity replication and optimal surface finish.

High-Precision CNC

5-axis machining centers achieve ±0.005mm tolerance for critical mold features, supporting automotive-grade dimensional requirements across all applications.

EDM Processing

Wire and sinker EDM capabilities handle complex geometries and deep ribs while achieving mirror-finish surfaces for cosmetic automotive components.

Hot Runner Systems

Valve-gated hot runner integration eliminates degating operations and improves cosmetic quality while reducing material waste in high-volume production.

CMM Inspection

Coordinate measuring machines provide full dimensional reports validating critical tolerances and ensuring PPAP documentation meets OEM requirements.

Insert Molding

Multi-material and overmolding processes combine rigid substrates with soft-touch surfaces or encapsulate metal inserts with precision positioning control.

Process Validation

Statistical process control monitors critical parameters continuously during production runs, ensuring long-term dimensional stability and quality consistency.

Want to see how our capabilities solve your specific engineering challenges?

Automotive-Grade Quality & Compliance Systems

Our quality management infrastructure meets the rigorous demands of automotive OEM suppliers. From IATF 16949 certification to complete PPAP documentation, every mold project follows protocols that ensure traceability, reliability, and regulatory compliance.

IATF 16949 Certified

Full automotive quality management system certification ensures every mold project follows standardized processes from initial design through mass production validation. Our facility maintains continuous compliance with regular audits and process improvements.

Complete PPAP Documentation

Production Part Approval Process documentation includes dimensional reports, material certifications, process flow diagrams, and control plans. We provide everything OEM suppliers need for customer submissions and regulatory compliance.

Continuous Monitoring

Statistical Process Control tracks critical dimensions throughout production runs. Real-time monitoring catches variations before they become problems, while comprehensive records provide full traceability for every manufactured part.

Ready to partner with a supplier that understands automotive quality standards?