Industrial Hardware & CNC Machined Components

Precision-engineered industrial hardware components and CNC machined parts delivering reliable performance in demanding applications. From custom fasteners to complex assemblies, we provide manufacturing excellence with global supply chain support.

- ✓ High Precision | High Stability | Fast Feedback

- ✓ Multi-Material Processing: Steel, Aluminum, Copper, Stainless

Critical Challenges in Industrial Hardware Component Manufacturing

Industrial hardware procurement demands precise technical understanding. These challenges directly impact production efficiency and assembly reliability.

High-Precision Fitting Requirements

Assembly components require ±0.01mm tolerances ensuring reliable mechanical function and interchangeability across production batches.

Batch-to-Batch Consistency

Production line reliability depends on dimensional consistency across thousands of parts for seamless assembly operations.

Multi-Material Processing

Different materials—steel, aluminum, copper, stainless—each require specialized tooling, machining parameters, and quality control.

Supply Chain Response Speed

Production schedules demand rapid supplier response for technical questions, design changes, and delivery coordination.

Comprehensive Industrial Hardware Manufacturing Services

Result-driven services supporting your complete component lifecycle from design optimization through volume production and delivery.

Drawing DFM Feedback

Manufacturability analysis optimizes designs for production efficiency, cost reduction, and quality improvement before tooling.

Precision CNC Machining

Advanced turning, milling, and multi-axis operations deliver tight tolerances across diverse materials with consistent quality.

Functional Component Design

Engineering support for custom hardware components optimized for specific applications and volume manufacturing requirements.

Heat & Surface Treatment

Complete finishing services including anodizing, plating, coating, and sandblasting for enhanced durability and performance.

Industry-Specific Hardware Component Solutions

Specialized manufacturing solutions addressing unique technical requirements across industrial sectors and application environments.

Engineering Machinery Connectors

Heavy-duty connecting components for construction and industrial equipment requiring high strength, wear resistance, and reliable performance under extreme loads and environmental conditions.

Robotics Structural Components

Precision structural parts for robotic systems demanding tight tolerances, lightweight materials, and exceptional dimensional stability for accurate positioning and movement control.

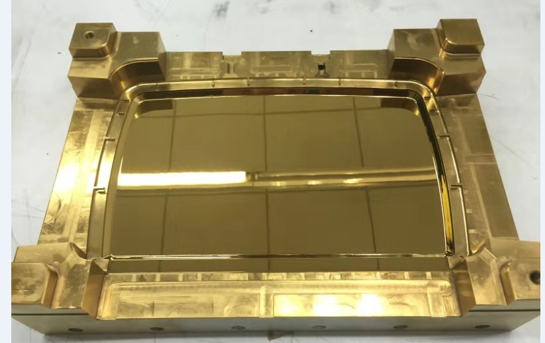

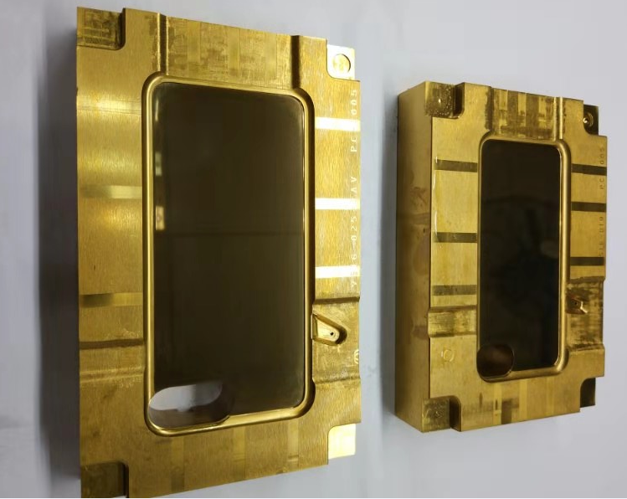

Smart Device Precision Hardware

Miniature precision components for intelligent equipment requiring advanced surface finishing, tight assembly tolerances, and consistent quality for high-volume consumer and industrial applications.

Frequently Asked Questions

What precision levels can your CNC machining achieve?

Our CNC machining centers routinely achieve ±0.01mm tolerances with surface finishes to Ra 1.6. For critical applications, we can hold tighter tolerances to ±0.005mm with specialized fixturing and temperature-controlled environments.

How do you control batch consistency and variation?

We implement Statistical Process Control (SPC) throughout production with in-process measurement at critical operations. First-article inspection establishes baseline, followed by systematic sampling with CMM verification. Process capability studies (Cpk ≥1.33) ensure consistent dimensional control across production runs.

Do you support UL/EN compliance inspection outputs?

Yes, we provide complete documentation packages including material certifications, dimensional inspection reports, surface finish measurements, and compliance statements. Our quality system supports customer-specific requirements for UL, EN, and other international standards.

How is small batch trial production priced?

Small batch pricing includes setup optimization, first-article validation, and process documentation. We provide transparent quotes showing unit costs across quantity breaks, typically with significant price reduction at 100, 500, and 1000+ piece volumes as setup costs are amortized.