Industrial Molds Manufacturing

Factory-direct tooling engineered for the demanding requirements of industrial equipment, automation systems, and smart manufacturing applications. Our molds deliver consistent precision across millions of cycles, supporting your production efficiency and quality standards.

- ✓ High-cycle durability tested beyond 1 million shots

- ✓ Engineering-grade materials expertise for technical applications

Industrial Mold Solutions Across Critical Applications

From factory automation to smart devices, our injection molds support the precise, durable components that power modern industrial systems. Each application benefits from specialized engineering that addresses unique material requirements, dimensional tolerances, and production volume demands.

Automation Components

Sensor housings, actuator enclosures, and robotic arm components requiring dimensional stability and material consistency for reliable automation performance. Our precision molds enable seamless assembly and long-term functionality in demanding industrial environments.

- High-precision positioning features for perfect alignment

- Engineering-grade resin compatibility (PA, PBT, PPS)

- Long-term dimensional stability across temperature variations

Electronic Enclosures

Protective housings for control panels, circuit boards, and electronic devices with EMI shielding capability, heat dissipation features, and environmental sealing requirements. Engineered to meet IP rating standards while maintaining manufacturing efficiency.

- Flame-retardant material options (UL94 V-0 rated)

- Precise mounting boss locations for PCB assembly

- IP rating compliance design with gasket channels

Machine Tool Components

Handles, guards, control knobs, and functional parts that withstand frequent use, chemical exposure, and mechanical stress while maintaining precise tolerances. Designed for ergonomic functionality and long-term durability in industrial settings.

- Wear-resistant materials for high-cycle applications

- Ergonomic surface textures for operator comfort

- UV and chemical resistance for harsh environments

Smart Device Housings

Enclosures for IoT sensors, monitoring devices, and industrial tablets requiring cosmetic excellence, antenna integration, and protective functionality. Multi-material capabilities enable both aesthetic appeal and technical performance in connected industrial equipment.

- RF transparency optimization for wireless connectivity

- Multi-material overmolding for soft-touch interfaces

- Drop test compliance design for field durability

Precision Engineering That Powers Industrial Reliability

Industrial applications demand more than basic manufacturing capability. Your components must perform consistently under stress, maintain dimensions across temperature variations, and deliver reliability that supports uninterrupted production operations. Our engineering approach addresses these requirements systematically.

Micro-Precision Tolerances

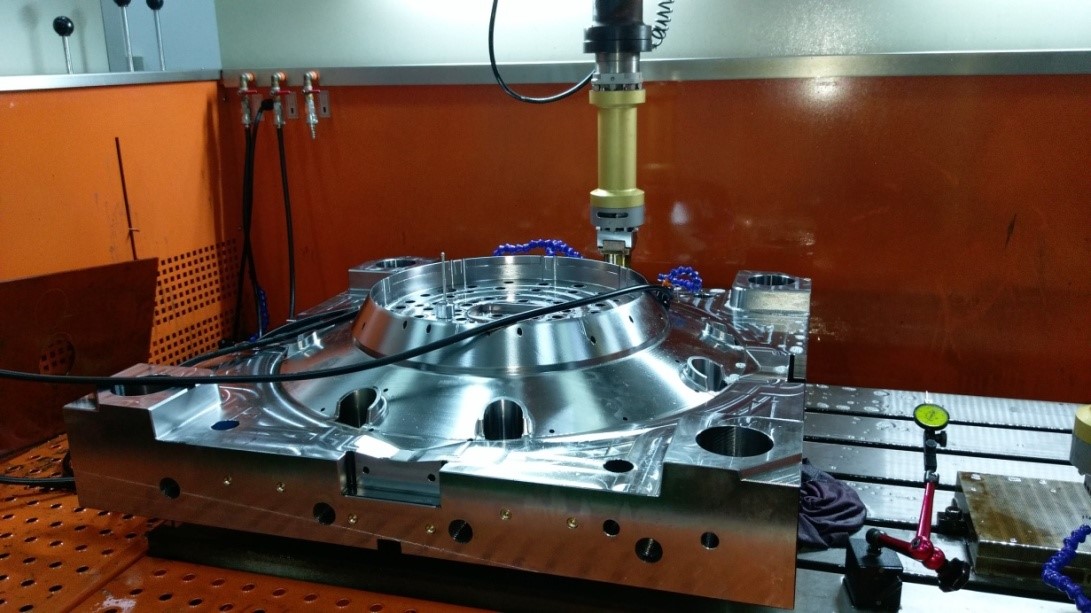

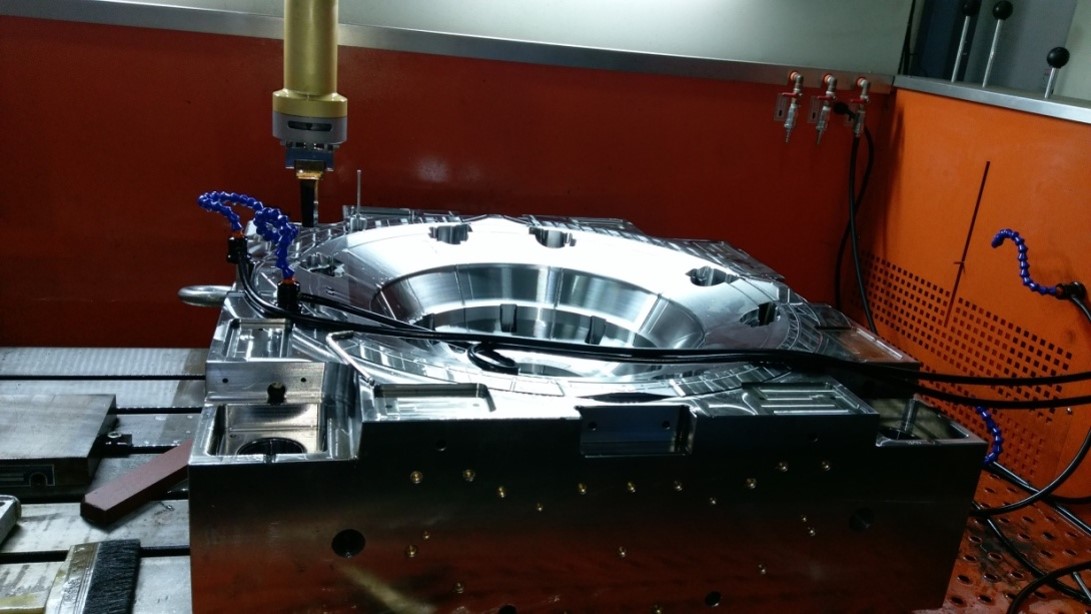

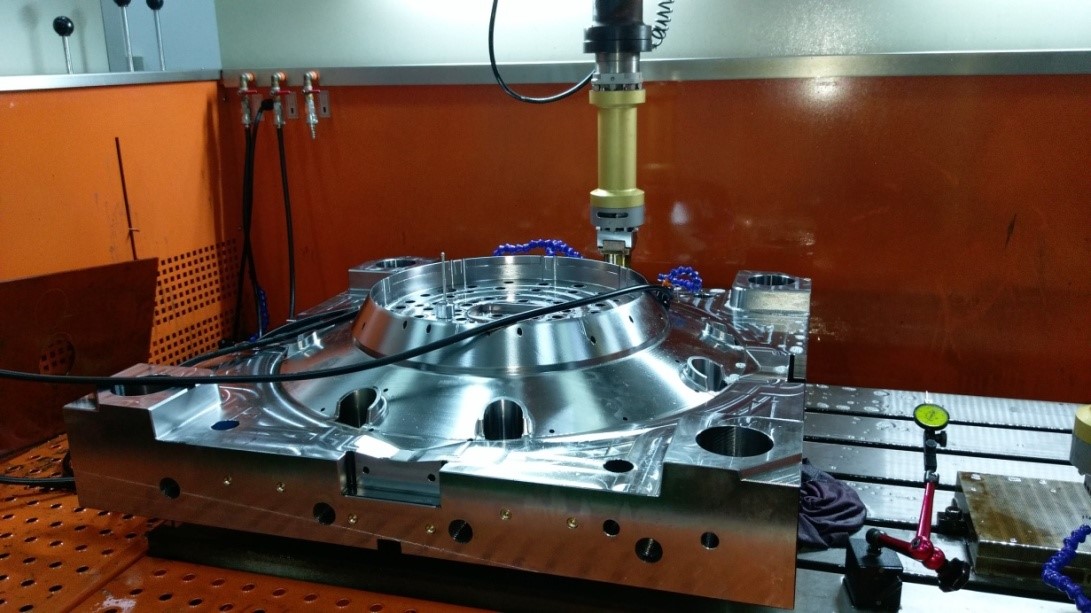

Advanced 5-axis CNC machining and EDM technology achieve dimensional accuracy down to ±0.01mm on critical features. This precision enables perfect assembly fit, eliminates adjustment requirements during installation, and ensures consistent mechanical performance across your entire production run. Every cavity is individually verified through CMM inspection before mold approval.

Material Science Expertise

Engineering-grade resins require specialized processing knowledge. Our team optimizes mold design for materials like glass-filled nylon, PEEK, PPS, and other high-performance polymers. We validate material flow, fiber orientation, and thermal characteristics through simulation, ensuring your parts deliver the mechanical properties your application demands without compromise.

Million-Cycle Durability

Industrial production volumes require molds built for longevity. Strategic steel selection, proper heat treatment, and optimized cooling design protect your investment. Our molds routinely exceed 1 million cycles while maintaining original dimensional accuracy, eliminating unexpected downtime and the substantial costs of emergency mold replacement or refurbishment.

Manufacturing Excellence in Motion

Watch our precision manufacturing processes, quality control systems, and finished components in operation. These videos demonstrate the engineering capabilities and attention to detail that ensure every mold meets industrial performance standards.

CNC Precision Machining & EDM Processing

Watch our advanced CNC machining centers and EDM equipment achieve micro-precision tolerances on complex mold cavities. This comprehensive video shows the technology behind our dimensional accuracy, surface finish quality, and the systematic approach we use to manufacture molds that deliver consistent results. See how our skilled technicians combine cutting-edge equipment with decades of experience to produce tooling that meets the most demanding industrial specifications.

Quality Control Systems & Automated Production

Discover how our coordinate measuring machines validate every critical dimension and how our automated production systems maintain consistent quality across thousands of cycles. This video demonstrates our comprehensive quality assurance protocols, from first article inspection through statistical process control during production runs, ensuring complete traceability and compliance with your engineering specifications. See the reliability your industrial applications require in action.

Systematic Approach to Industrial Mold Development

Our structured process eliminates uncertainty and accelerates time-to-market. From initial concept through volume production, each phase incorporates validation steps that build confidence and minimize risk. This methodology ensures your industrial molds perform as engineered from day one.

Requirements Analysis

Engineers review part geometry, material specifications, and production volume to identify critical features and potential challenges.

DFM Optimization

Design for manufacturability feedback identifies improvements that reduce costs and enhance quality before tooling begins.

Flow Simulation

Moldflow analysis predicts material behavior, identifies potential defects, and optimizes gate locations and cooling design.

Precision Machining

Advanced CNC and EDM equipment produces mold components to exact specifications with verified dimensional accuracy.

Trial & Validation

First article inspection confirms dimensional compliance while process parameters are optimized for production efficiency.

Accelerated Development

Virtual testing through simulation reduces physical trials by 60%, compressing development timelines from months to weeks. Your products reach market faster while maintaining complete validation and quality assurance throughout the process.

Cost Predictability

Upfront optimization eliminates expensive mold modifications after steel cutting. Our clients typically save 25-40% compared to reactive approaches, while achieving superior first-article success rates that prevent production delays.

Quality Certainty

Multi-stage validation from design through production ensures dimensional accuracy, material performance, and long-term durability. Statistical process control maintains consistency across your entire production run, protecting your reputation.

Advanced Manufacturing Technologies

Our technical infrastructure combines state-of-the-art equipment, simulation software, and deep process expertise to deliver industrial molds that meet the most demanding specifications. Each capability contributes to the precision, reliability, and longevity your applications require.

CNC Machining

Advanced machining centers achieve complex geometries and micro-precision tolerances on hardened tool steels with exceptional surface finish. Our multi-axis capabilities enable intricate mold features that would be impossible with conventional 3-axis equipment, delivering dimensional accuracy down to ±0.01mm on critical features while maintaining efficient production cycles.

EDM Processing

Wire and sinker EDM capabilities handle intricate features, deep ribs, and mirror finishes impossible with conventional machining methods. This technology enables sharp internal corners, complex cooling channels, and ultra-smooth surface finishes for Class A cosmetic requirements, while processing hardened steels after heat treatment to maintain optimal mold longevity.

Moldflow Simulation

Advanced flow analysis predicts filling patterns, weld lines, and warpage before cutting steel, optimizing gate locations and cooling systems. Virtual testing eliminates costly trial-and-error modifications by validating material behavior, identifying potential defects, and confirming dimensional stability before physical mold construction begins, ensuring first-shot success.

CMM Inspection

Coordinate measuring machines provide complete dimensional verification with detailed reports documenting compliance to engineering specifications. Our climate-controlled inspection lab eliminates thermal variation errors, while automated measurement routines ensure repeatable verification of all critical dimensions, delivering the traceability and documentation industrial applications demand.

Industrial-Grade Quality Management Systems

Our quality infrastructure meets the stringent demands of industrial manufacturing. From ISO 9001 certification to complete process documentation, every mold project follows protocols that ensure traceability, consistency, and compliance with industry standards.

ISO 9001 Certified

Comprehensive quality management system certification ensures standardized processes from initial design through final inspection. Regular audits and continuous improvement programs maintain compliance and drive operational excellence.

Complete Documentation

Detailed inspection reports, material certifications, process parameters, and dimensional data provide full traceability. First article inspection packages include CMM measurement data for all critical features.

Process Validation

Statistical process control monitors key parameters throughout production runs. Real-time data collection enables immediate corrective action when variations occur, preventing defects before they reach your facility.

Real Results in Industrial Applications

From concept to high-volume production, our industrial mold solutions deliver measurable improvements in quality, efficiency, and reliability. Each project demonstrates our commitment to engineering excellence and manufacturing precision.

Automation

Automation

Precision Sensor Housing Assembly

European automation manufacturer required multi-cavity mold producing identical sensor housings with ±0.015mm tolerance on mounting features. Previous supplier experienced 18% rejection rate due to flash and dimensional variation.

Implemented balanced runner system with individual cavity temperature control. Moldflow simulation optimized gate design to eliminate weld lines in critical mounting areas. EDM mirror finish on parting surfaces eliminated flash completely.

Electronics

Electronics

Glass-Filled Nylon Connector Body

Industrial connector required 30% glass-filled PA66 with precise pin alignment for electrical contacts. Fiber orientation control critical for mechanical strength. Previous tooling showed inconsistent fiber distribution causing 25% failure rate in assembly testing.

Strategic gate placement ensured optimal fiber flow through pin cavities. Material flow simulation validated fiber alignment in high-stress zones. Mold design incorporated precise tolerances for insert positioning achieving perfect pin alignment.

Smart Devices

Smart Devices

IP67 Control Panel Enclosure

North American manufacturer needed flame-retardant enclosure meeting IP67 sealing requirements for harsh industrial environments. Design included complex snap-fit features and precise gasket channels. Environmental testing revealed inconsistent seal performance.

Optimized gasket channel geometry through flow simulation to prevent sink marks and ensure uniform wall thickness. Implemented conformal cooling to minimize warpage. Multi-point ejection system maintained dimensional stability on large thin-walled sections.

State-of-the-Art Production Facilities

Our manufacturing facility combines advanced equipment, skilled technicians, and systematic quality control to deliver precision molds consistently. Take a visual tour through the departments that transform your designs into production-ready tooling.