Traditional porcelain insulators are notorious for their brittleness. A simple mechanical impact during transport or even routine thermal stress on the line can cause micro-cracks, leading to catastrophic shattering and immediate line faults. Here’s the deal: Unexpected downtime costs you thousands in emergency repairs and damages your reputation with clients who demand 99.9% reliability. Relying on outdated ceramic technology in modern low-voltage distribution is a risk your network cannot afford.

The solution lies in switching to Low Voltage Pin Type Insulators made of BMC (Bulk Molding Compound). By utilizing this advanced thermoset composite, you eliminate the fragility inherent in ceramics. With superior mechanical strength, precision molding, and high arc resistance, BMC insulators provide the robust stability your infrastructure requires.

Table of Contents

What exactly is a BMC low voltage pin type insulator?

A BMC low voltage pin type insulator is a specialized electrical component designed to isolate live conductors from support structures in distribution networks, typically operating between 600V and 33kV. Unlike the suspension insulators you might see on high-tension transmission towers, pin insulators are mounted rigidly on a pin which is secured to a cross-arm on a utility pole. The conductor wire rests in a groove on the top of the insulator and is bound securely to it.

The defining feature here is the material: Bulk Molding Compound (BMC). This is not a simple plastic; it is a high-performance thermoset composite consisting of a polyester resin matrix reinforced with glass fibers and mineral fillers. This combination creates a component that acts as both a mechanical support and a dielectric barrier. In low voltage applications, these insulators are critical for maintaining the safety of the grid by preventing current leakage to the ground.

You might be wondering why this specific composite is taking over the market. It fundamentally changes the behavior of the component. While porcelain is inert but brittle, BMC is chemically engineered to be tough. It absorbs mechanical shock that would shatter glass or clay. For a procurement manager or engineer, this means the product that leaves the factory is the same one that arrives at the installation site, without the hidden hairline fractures that plague ceramic shipments.

How does BMC material composition enhance performance?

The performance capabilities of BMC insulators are derived directly from their sophisticated chemical makeup. At its core, the material is a mixture of unsaturated polyester resin, short-cut fiberglass strands (typically 5-20mm in length), and inert mineral fillers like calcium carbonate or talc. The resin acts as a binder, creating a dense, void-free matrix, while the glass fibers provide the tensile and flexural strength necessary to withstand the weight of heavy conductors and wind loads.

Crucially, BMC is a thermoset material. This is a vital distinction from thermoplastics. Once BMC is cured under heat and pressure, its chemical structure is permanently cross-linked. It will not melt, soften, or flow, even when exposed to high operating temperatures. This makes it incredibly stable. The specific formulation of our Duroplast Insulators ensures they remain stable even under extreme thermal stress, maintaining their dimensional integrity from -40°C up to +140°C.

But here’s the kicker regarding mechanical stability. The random orientation of the glass fibers within the molded part creates isotropic strength—meaning it is strong in all directions. This is unlike wood or certain extruded plastics that have a “grain” or weak direction. Whether the stress comes from the downward weight of snow-laden lines or the lateral pull of a turn in the route, the BMC material resists deformation uniformly.

How do BMC pin insulators compare to traditional porcelain?

When you compare BMC directly with traditional porcelain, the differences are stark, particularly in terms of durability and precision. Porcelain has been the industry standard for over a century, but it suffers from significant limitations. It is heavy, difficult to manufacture to tight tolerances due to warping during the firing process, and dangerously brittle. A porcelain insulator dropped from a ladder is garbage; a BMC insulator dropped from the same height is likely ready to be installed.

Dimensional accuracy is another area where BMC shines. Porcelain insulators often require cementing metal pins into the ceramic body because the ceramic threads cannot be molded precisely enough to guarantee a secure fit. BMC, on the other hand, is compression molded. This allows for the integration of precise, threaded inserts directly into the body during the molding process. Whether you need standard or custom low voltage support insulators , BMC offers a precision that fired clay cannot match.

Let’s look at the numbers.

Table 1: BMC vs. Porcelain Properties

| Feature | BMC (Bulk Molding Compound) | Traditional Porcelain | |

|---|---|---|---|

| Impact Resistance | High (Shatter-resistant) | Low (Brittle) | |

| Weight | Lightweight (~70% lighter) | Heavy | |

| Dimensional Tolerance | Tight / Precision Molded | Loose / High Variance | |

| Thermal Shock | Excellent | Prone to cracking | |

| Installation | Single piece / Bolt-on | Multi-part / Cemented |

What is the manufacturing process for BMC insulators?

The manufacturing of BMC insulators is a lesson in efficiency and consistency. It typically employs a compression molding process. It begins with the preparation of the dough-like molding compound, where resins, fibers, and fillers are mixed to a precise recipe. This “charge” is weighed accurately and placed into a heated steel mold, which is typically maintained at temperatures between 150°C and 180°C.

A hydraulic press then closes the mold with immense force, often between 100 and 300 tons. Under this heat and pressure, the BMC flows into every cavity of the mold, encapsulating any metal inserts that were placed inside. The heat triggers a chemical reaction, curing the resin and locking the shape permanently. This molding process allows for customized insulator designs that fit specific cross-arm geometries or unique conductor attachment methods.

What’s the real story behind production speed? Because the curing reaction happens rapidly within the mold (often in just a few minutes), the cycle times for BMC are significantly faster than the days required to dry and fire ceramic insulators. This efficiency not only reduces energy consumption but also allows manufacturers to scale production quickly to meet large infrastructure project demands without the long lead times associated with porcelain kilns.

Where are these low voltage insulators most commonly used?

BMC low voltage pin insulators are versatile workhorses found across the electrical infrastructure. Their primary habitat is overhead distribution lines, specifically for voltages ranging from 1kV to 33kV. Here, they support the conductors that bring power into neighborhoods and industrial parks. Their weather resistance makes them ideal for this outdoor environment, handling UV radiation, rain, and temperature fluctuations without degrading.

Beyond the utility pole, these insulators are essential inside electrical equipment. You will find them acting as busbar supports in low voltage switchgear cabinets, where they must prevent arcing between heavy copper bars while withstanding the mechanical forces generated by short-circuit currents. They are also increasingly common in renewable energy systems, such as solar combiner boxes and wind turbine nacelles, where compact, lightweight, and durable insulation is required.

Here is the breakdown of typical use cases.

Table 2: Common Application Sectors

| Industry | Application | Benefit | |

|---|---|---|---|

| Power Distribution | Overhead Lines (1-3 kV) | Weather & UV resistance | |

| Switchgear | Busbar Supports | High dielectric strength | |

| Renewables | Solar Combiner Boxes | Compact & Lightweight | |

| Industrial | Control Cabinets | Vibration damping | |

| Transportation | Railway Insulation | Impact durability |

How does the pin type design differ from post insulators?

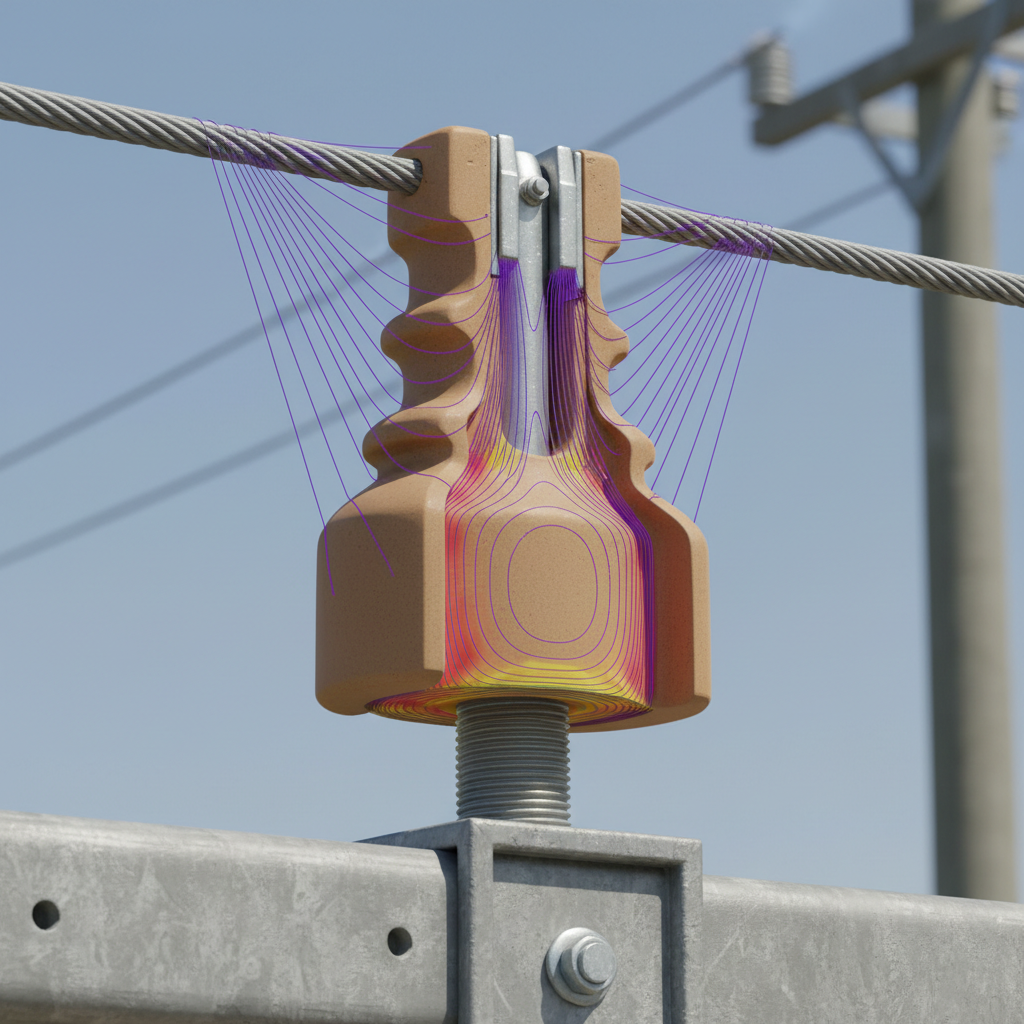

While both pin and post insulators serve the function of isolation and support, their designs and specific applications diverge significantly. A pin insulator is characterized by its skirted, often bell-like shape, designed to shed water and increase the creepage distance (the path electricity must travel across the surface). It is mounted on a spindle or pin that protrudes upwards from a cross-arm. The load it carries is primarily the vertical weight of the conductor resting on top of it.

In contrast, a post insulator is typically a solid column, often with a flanged base that bolts directly to a structure. Post insulators are engineered to handle not just compressive loads (weight) but also significant bending (cantilever) forces. You will see post insulators in substations supporting heavy switchgear or acting as rigid stand-offs for busbars. Pin insulators are the economical choice for linear distribution where the mechanical loads are moderate and primarily vertical.

Consider this when planning your grid layout. If you are running a straight distribution line, pin insulators are efficient and cost-effective. If you are building a substation or a corner pole where the insulator must resist the sideways pull of the wire, a post insulator or a hybrid design utilizing the high strength of BMC might be the better engineering choice.

Table 3: Pin vs. Post Insulator Characteristics

| Feature | Pin Insulator | Post Insulator | |

|---|---|---|---|

| Mounting | Mounted on Pin/Spindle | Bolted Flange Base | |

| Load Type | Conductor Weight (Compression) | Bending / Cantilever | |

| Primary Use | Overhead Distribution Lines | Substations / Busbars | |

| Cost Profile | Economical | Higher Cost | |

| Voltage Range | Low to Medium (up to 33kV) | Medium to High (up to 1100kV) |

What are the installation benefits of BMC pin insulators?

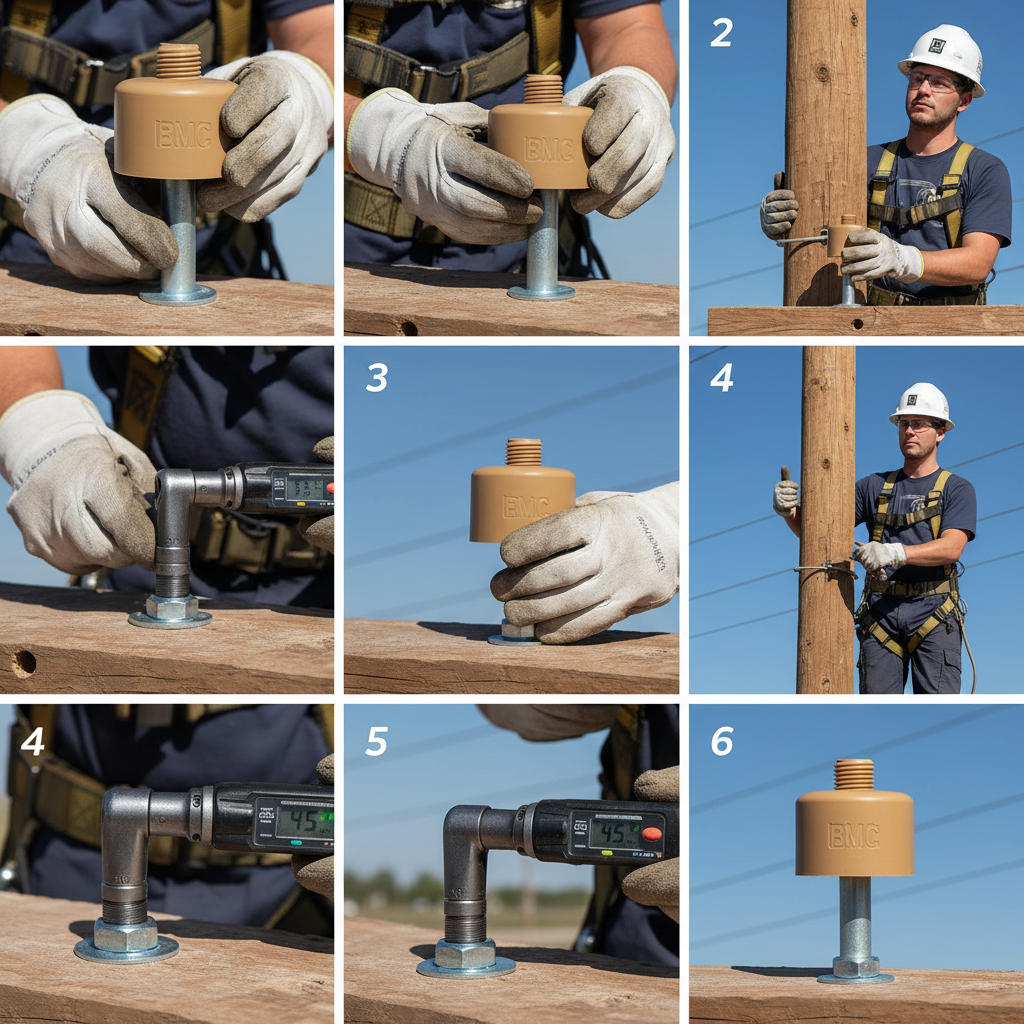

For the linemen and technicians in the field, switching to BMC insulators makes a tangible difference in their daily work. The most immediate benefit is weight. A BMC insulator can weigh 70% less than its porcelain equivalent. When you are hauling a crate of insulators up a utility pole or carrying them into a remote site, that weight reduction translates to less fatigue and a lower risk of handling injuries.

Furthermore, the integration of threaded inserts (made of brass or zinc-plated steel) into the BMC body simplifies the attachment process. There is no need for the messy, time-consuming cementing process often required to join porcelain insulators to their pins. Technicians can simply spin the insulator onto the pin or bolt it to the cross-arm using standard tools. This “bolt-on” capability speeds up deployment significantly.

Ready for the good part? Durability during installation is a massive cost saver. It is not uncommon for ceramic insulators to chip or crack if they are jostled in the truck or bumped against a cross-arm during mounting. A chipped ceramic insulator is compromised and must be discarded. BMC insulators are resilient; accidental drops or bumps rarely affect their performance, reducing waste and frustration on the job site.

Table 4: Installation Comparison

| Factor | BMC Insulator | Ceramic Insulator | |

|---|---|---|---|

| Handling Weight | < 1kg (Typical) | 2-3kg+ | |

| Breakage Risk | Negligible | High | |

| Attachment | Integrated Thread / Bolt-on | Cementing / Lead Threads | |

| Tooling | Standard Wrench | Specialized / Adhesive |

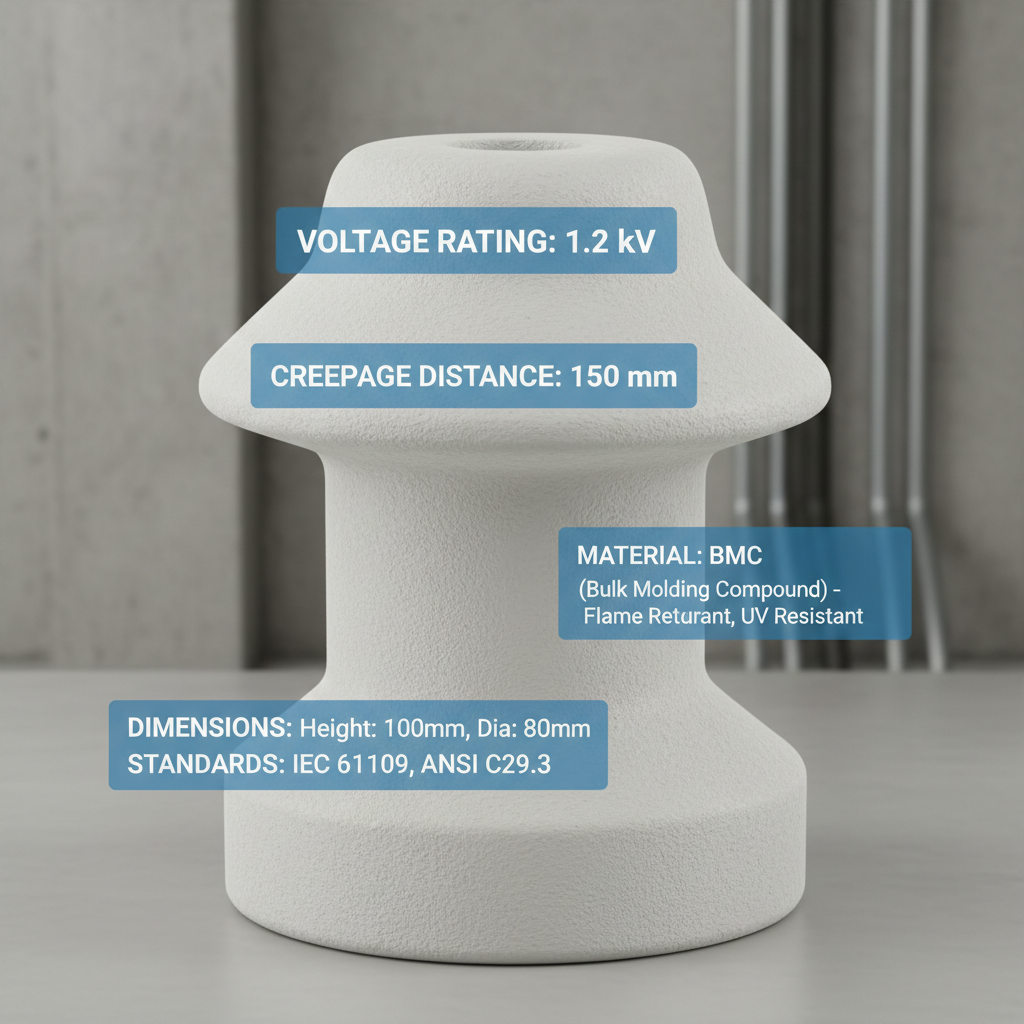

What technical specifications should you look for?

When specifying BMC insulators for your project, it is essential to look beyond just the voltage rating. You need to verify the dielectric strength, which for high-quality BMC typically ranges around 10 kV/mm, ensuring a robust safety margin against flashovers. Tensile strength is another critical metric; reliable pin insulators should withstand a tensile load greater than 3.2 kN to ensure they don’t fail under line tension.

You should also check the flammability rating. Top-tier BMC materials are rated UL 94 V0, meaning they are self-extinguishing and will not contribute to the spread of fire—a critical safety feature in electrical fires. Finally, ensure the operating temperature range matches your environment. A specification of -40°C to +130°C covers most global applications, from freezing winters to baking summers inside an industrial enclosure.

It turns out the specs speak for themselves. The combination of electrical insulation and mechanical robustness in a single material data sheet is why engineers are moving away from multi-material assemblies.

Table 5: Typical BMC Insulator Specifications

| Parameter | Specification Range | |

|---|---|---|

| Rated Voltage | 600V – 33kV (Design dependent) | |

| Dielectric Strength | ~10 kV/mm | |

| Operating Temp | -40°C to +130°C | |

| Flammability | UL 94 V0 (Self-extinguishing) | |

| Tensile Strength | > 3.2 KN | |

| Inserts | Brass or Zinc-plated Steel |

Which safety standards and certifications apply?

In the electrical industry, compliance is non-negotiable. For low voltage switchgear and controlgear assemblies, the overarching standard is DIN EN 61439-1. Insulators used within these assemblies must meet the rigorous thermal and mechanical requirements set forth in this standard. Additionally, the material itself often carries a UL (Underwriters Laboratories) recognition, specifically regarding its flammability (UL 94) and electrical tracking resistance.

For international markets, look for RoHS and REACH compliance. These certify that the manufacturing of the BMC material does not involve hazardous substances like lead or mercury, aligning with global sustainability goals. Always ensure your manufacturer adheres to certified production standards like ISO 9001 quality management systems. This traceability ensures that every batch of insulators performs exactly as the one before it.

Why does this matter? Using uncertified insulators puts your entire operation at risk of liability. If a fire starts or a line falls, the first thing investigators look for is whether the components met the required safety standards. Certified BMC components provide that layer of legal and operational protection.

How does Schmidt GmbH ensure insulator quality?

Quality is not an accident; it is the result of intention and experience. Schmidt GmbH leverages over 65 years of expertise in plastic processing and mold making. This deep institutional knowledge translates into a production process that is tightly controlled from start to finish. It begins with the strict selection of raw BMC materials from trusted suppliers, ensuring consistent fiber content and resin quality.

Throughout the molding process, automated monitoring systems track pressure, temperature, and cycle times to ensure optimal curing. But technology is backed by human expertise. Rigorous testing protocols, including visual inspections, dimensional checks, and electrical punch tests, are applied to verify that every insulator meets the German engineering standards the company is known for.

Here is the bottom line. When you source from a manufacturer with in-house tool making and design capabilities, you aren’t just buying a part; you are buying the assurance that the tool that made the part was designed by the same experts who understand the material properties. This holistic approach eliminates the defects common in disjointed supply chains.

Conclusion

The shift from porcelain to BMC in low voltage pin type insulators is more than just a change in material; it is an upgrade in reliability, safety, and operational efficiency. By choosing BMC, you gain a component that is lighter, stronger, and far more resistant to the physical and environmental stresses that cause traditional insulators to fail. You reduce installation times, cut down on breakage losses, and secure your network against downtime.

Investing in quality composite insulation is an investment in the long-term resilience of your electrical grid. Don’t let brittle technology be the weak link in your power distribution.

Ready to upgrade your infrastructure? Request a full product catalog today to see our complete range of high-performance BMC insulators.

Frequently Asked Questions

Q1: What is the expected lifespan of a BMC pin type insulator?BMC insulators are designed for longevity. In indoor switchgear applications, they can easily last 20+ years. For outdoor use, high-quality BMC formulations with UV stabilizers retain significant mechanical strength (up to 60%) even after 10 years of harsh exposure, far outlasting the maintenance cycles of brittle ceramic alternatives which may crack due to thermal cycling.

Q2: Can BMC insulators be used in high-pollution coastal environments?Yes. BMC materials are naturally hydrophobic (water-repelling), which prevents the formation of continuous water films that lead to electrical flashovers. Their excellent resistance to salt spray and chemical corrosion makes them a superior choice for coastal zones or industrial areas with high pollution levels where ceramic glazes might degrade.

Q3: Are custom shapes available for specific voltage requirements?Absolutely. Unlike porcelain, which requires complex turning and firing processes, BMC is compression molded. This allows manufacturers like Schmidt GmbH to efficiently produce custom geometries with integrated inserts to meet specific creepage distance requirements or unique mounting configurations for your project.

Q4: How does BMC perform in extreme temperatures compared to thermoplastics?BMC is a thermoset material, meaning it creates a permanent chemical bond when cured and does not melt. It maintains its structural integrity and electrical properties in temperatures ranging from -40°C to +140°C. Standard thermoplastics, by contrast, might soften, creep, or deform under similar heat stress, risking structural failure.

Q5: What is the difference between BMC and SMC insulators?Both are fiber-reinforced composites, but they differ in fiber length and application. BMC (Bulk Molding Compound) uses shorter glass fibers and is better suited for complex, intricate shapes like pin insulators with threaded inserts. SMC (Sheet Molding Compound) uses longer fibers for higher strength in large structural parts (like panels) but offers less design flexibility for small, detailed electrical components.