Home Appliances & Furniture Components

Mold manufacturing with complete engineering control, Our precision tooling delivers the dimensional accuracy, surface quality, and durability that home appliance and furniture markets demand.

- ✓ Long-term service to European and American brand supply chains

- ✓ Multi-material and multi-process structural capabilities

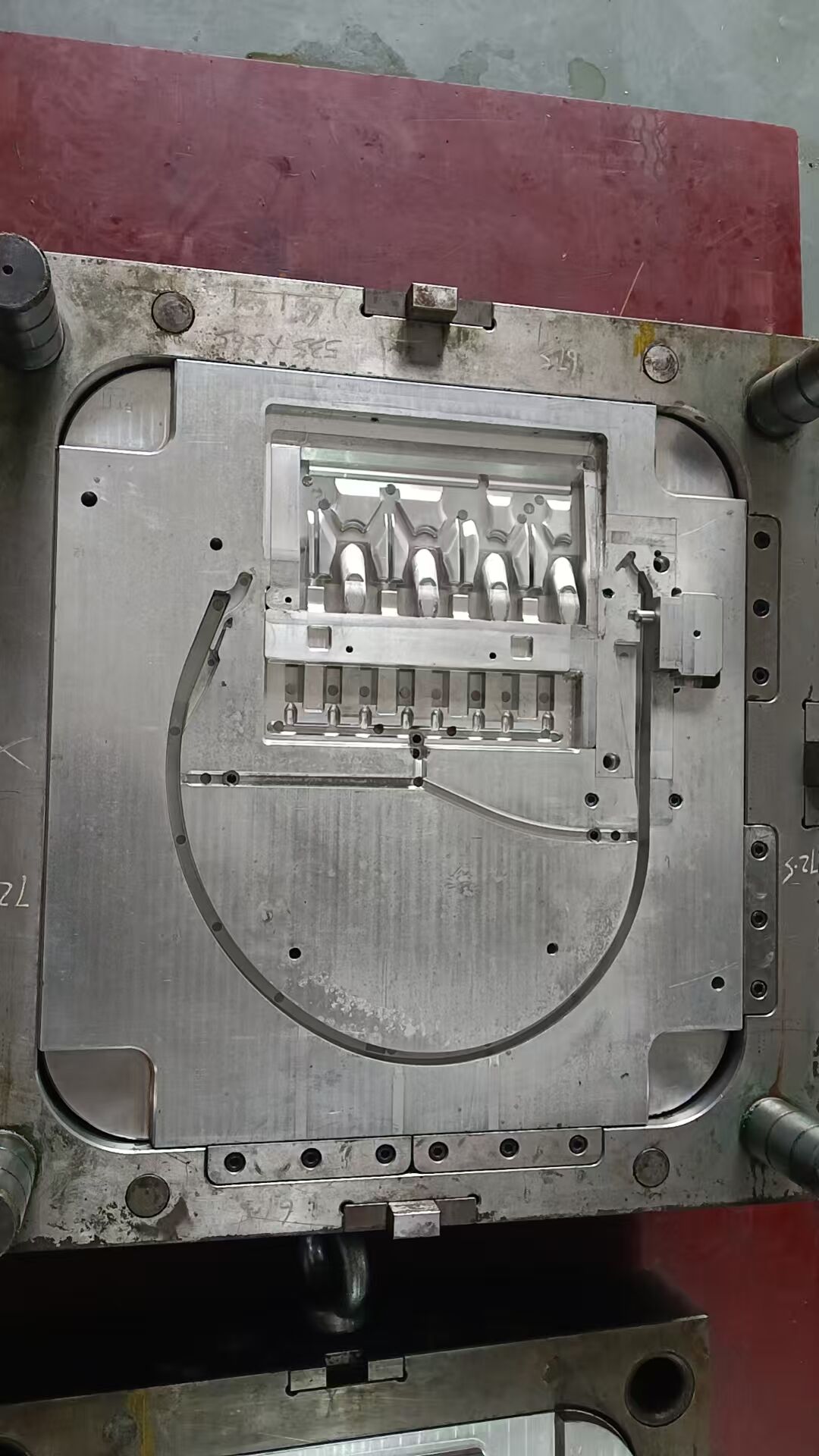

Why Home Appliance & Furniture Molds Require Specialized Expertise

Home appliance and furniture components face unique engineering challenges that distinguish them from standard injection molding. Understanding these critical requirements helps avoid costly design revisions and production failures.

Appearance & Touch Quality

Class A surfaces with consistent texture, color matching, and premium tactile feel for long-term use.

Thermal Performance

Heat-resistant materials maintaining dimensional stability under thermal stress for reliable appliance operation.

Structural Durability

Large parts withstanding mechanical stress, impact loads, and repeated use while maintaining tight tolerances.

Cost-Quality Balance

Optimized tooling delivering premium quality at competitive costs through smart material and process selection.

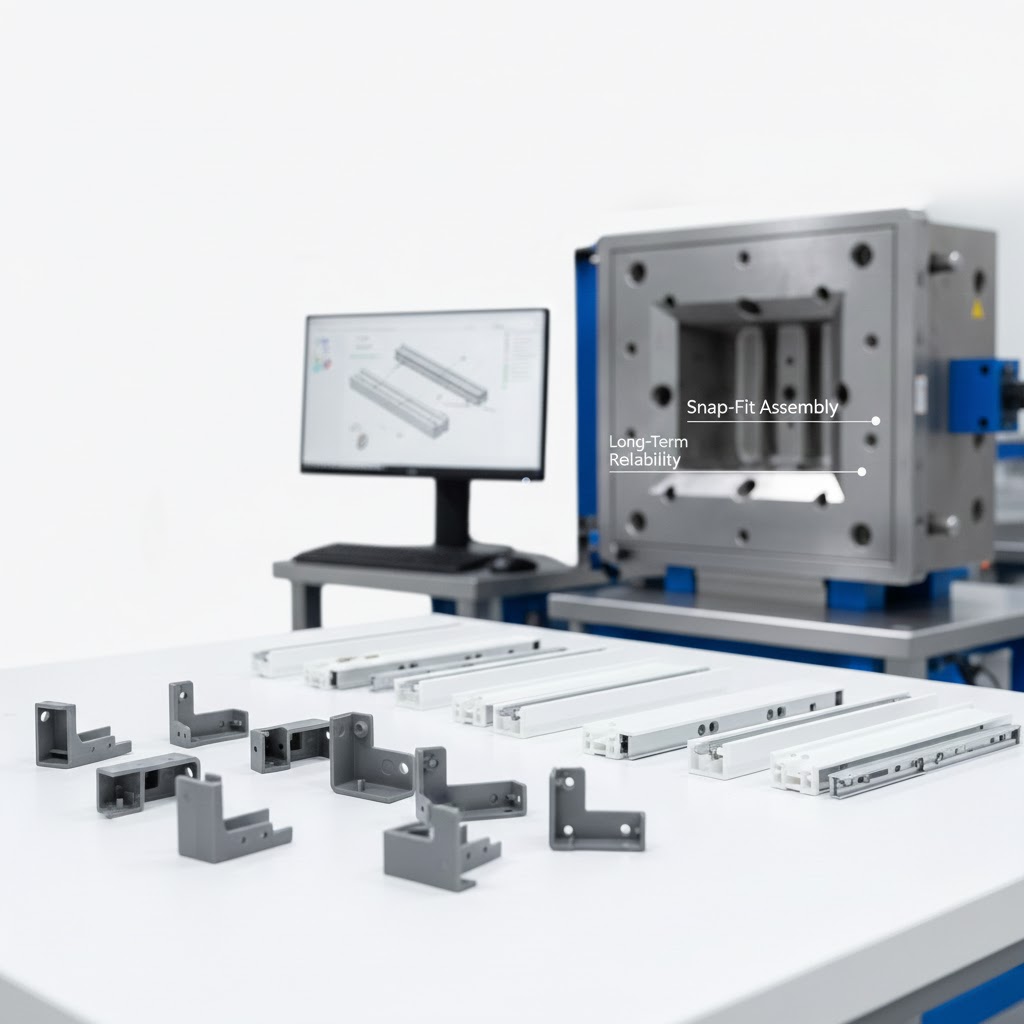

Comprehensive Engineering & Production Support

Service-oriented approach ensuring every phase from prototype to mass production receives expert engineering support and systematic quality control.

Prototype & Production Ramp-Up

Trial production validates design, optimizes parameters, and ensures smooth transition to volume manufacturing.

Multi-Material & Process Integration

Overmolding, insert molding, and multi-shot techniques for integrated component solutions.

Advanced Engineering Analysis

Moldflow simulation and DFMEA risk assessment identify issues before tooling, reducing costs and time.

Volume Production Management

Dedicated project management ensuring consistent quality, on-time delivery, and rapid technical support.

Specialized Solutions for Home Appliance & Furniture Components

Tailored mold engineering addressing the specific requirements of different component categories, from structural housings to precision functional parts.

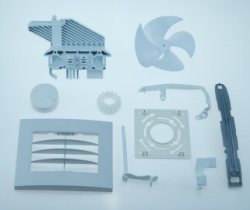

Appliance Housing & Structural Components

Large-format molds for refrigerator panels, washer drums, and microwave cavities with warpage control and optimized cooling for tight tolerances.

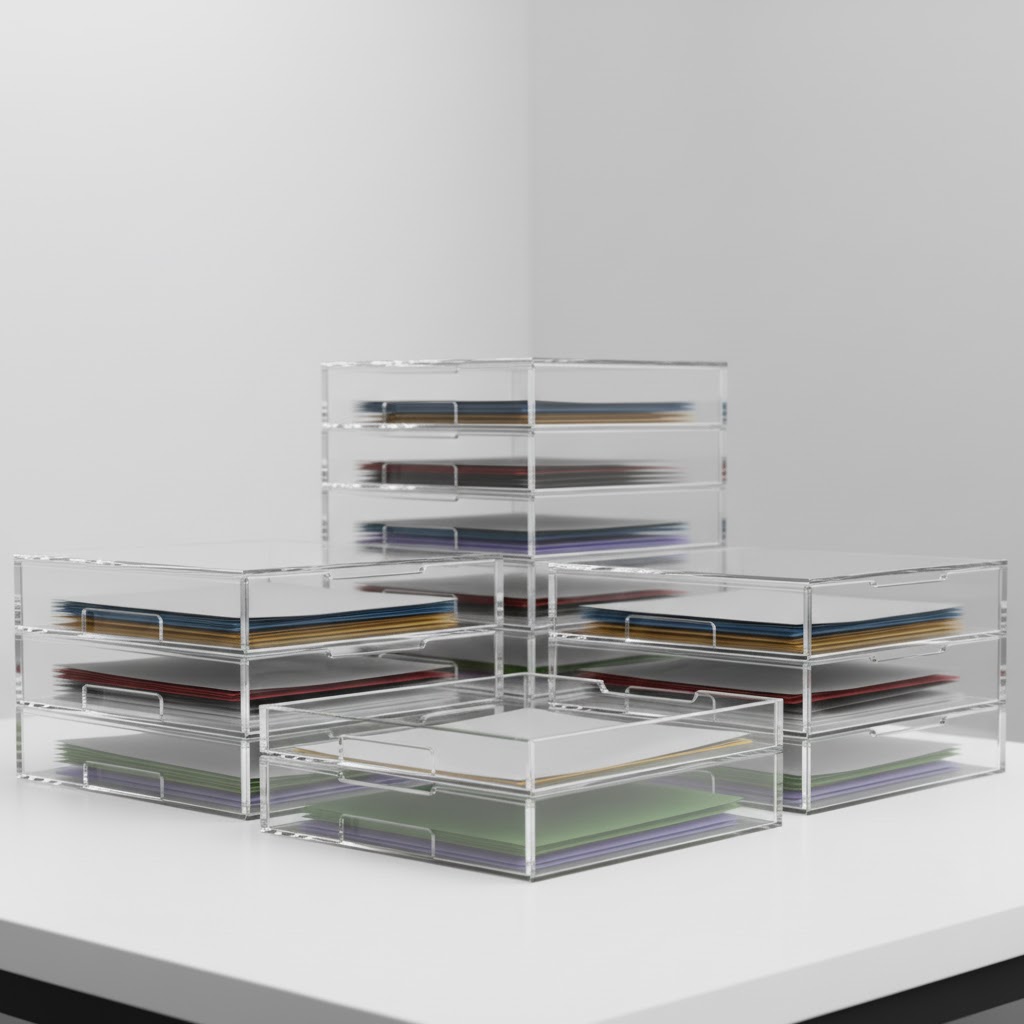

Furniture Clips, Brackets & Framework

Precision molds for edge clips, corner brackets, and drawer slides optimized for snap-fit assembly and long-term mechanical reliability.

Thermoplastic & Thermoset Complex Structures

Advanced molding for glass-filled nylon, PC/ABS blends, and thermoset composites with optimized fiber orientation and dimensional precision.