Electrical Connectors & Insulation Parts

Electrical connectors and insulation components engineered for reliability and performance. Engineering-driven manufacturing delivering high stability materials and consistent quality for industrial equipment, appliances, and power distribution applications worldwide.

- ✓ Precision Electrical Connectors • Engineering-Driven • Continuous Stable Supply

- ✓ High Stability & Reliability Materials • Proven Production Systems

Critical Requirements in Electrical Component Manufacturing

Electrical connector and insulation part procurement faces specific challenges requiring engineering expertise and responsive support.

High Electrical Safety Standards

Components must meet rigorous electrical safety requirements including voltage withstand, insulation resistance, and arc resistance for product certification and market access.

Slow Supplier Response

Production delays caused by unresponsive suppliers lacking technical expertise to address design questions and engineering changes quickly.

Poor Technical Communication

Ineffective engineering dialogue and lack of DFM feedback creates quality issues and delays in bringing products to market successfully.

Our Value Proposition

Three core advantages establishing trust and delivering consistent value to electrical component customers worldwide.

Factory Direct, Transparent Pricing

Direct manufacturer eliminating intermediaries ensures competitive pricing with transparent cost structure and consistent quality control throughout production.

Engineering-Driven Fast Response

Technical team providing rapid engineering feedback, DFM analysis, and proactive problem-solving accelerates development and production timelines.

Export Experience & Stable Delivery

Proven track record serving EU/US markets with reliable delivery performance and quality standards meeting international requirements.

Comprehensive Engineering & Manufacturing Support

Complete service portfolio supporting customers from initial concept through volume production and ongoing quality assurance.

Technical Consulting & Design Review

Expert engineering consultation optimizes designs for electrical performance, manufacturability, and cost efficiency.

Sample Production & Volume Ramp

Prototype development with validation testing supporting smooth transition to volume manufacturing.

Testing Reports & Quality Tracking

Comprehensive electrical and dimensional testing with complete documentation supporting customer qualification.

Global Logistics & After-Sales

Coordinated international shipping with responsive technical support ensuring customer production continuity.

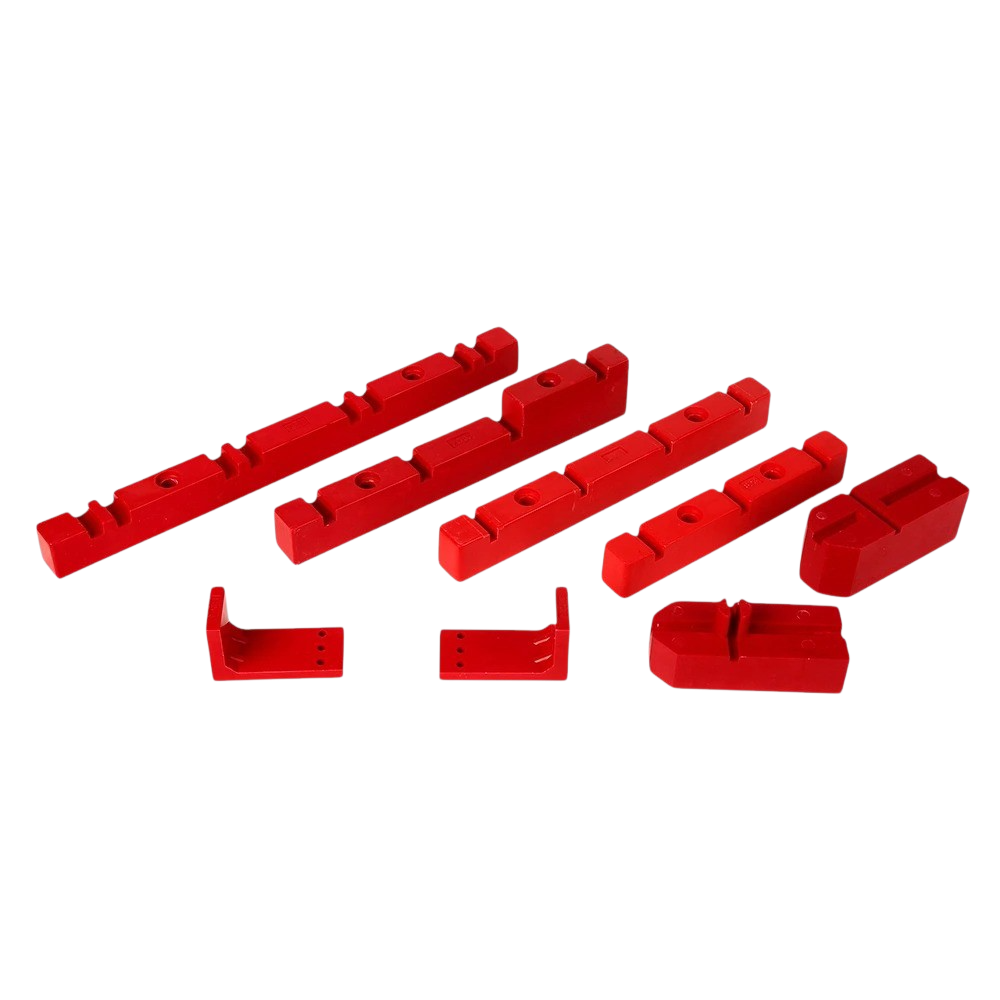

Electrical Connectors & Insulation Components

Comprehensive product portfolio engineered for diverse electrical applications with optimized material selection and precision manufacturing.

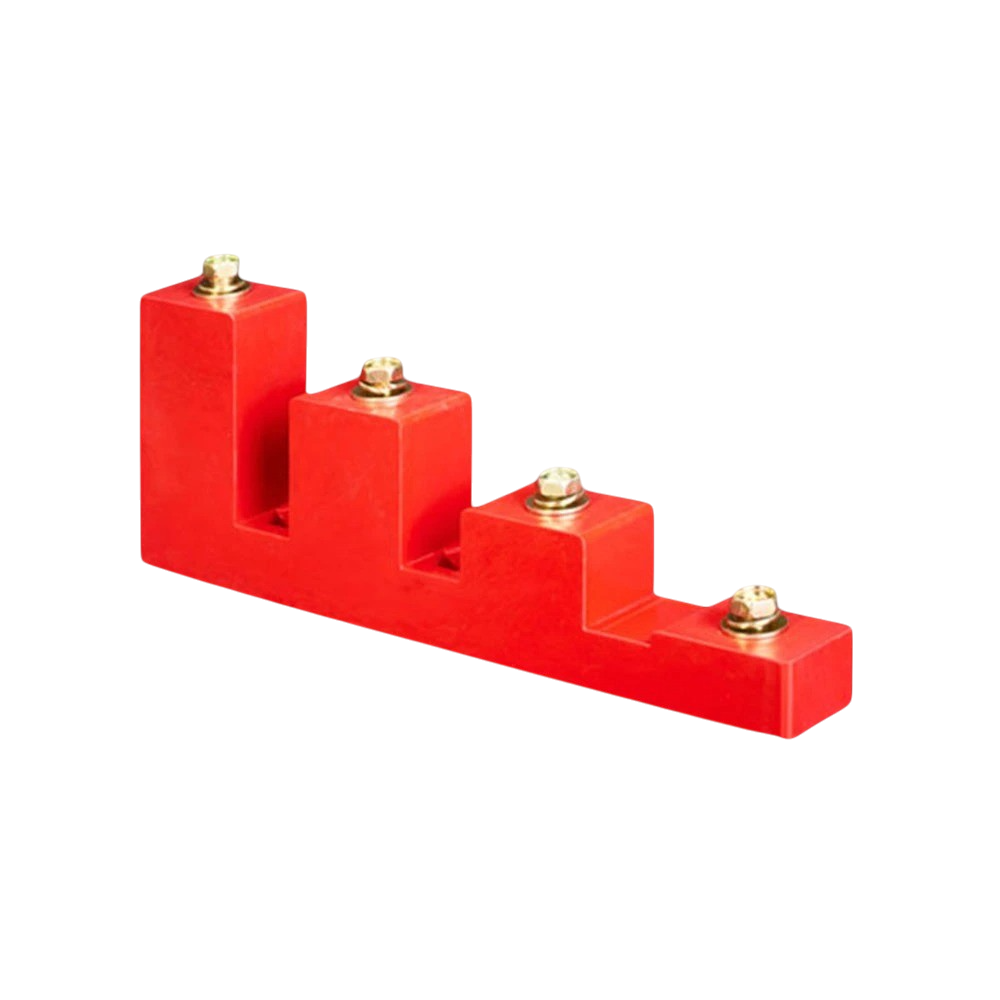

Power Electrical Connectors

Heavy-duty connectors for power distribution applications with low contact resistance and high current capacity.

Industrial Equipment

Busbar Clamps & Holders

Precision busbar connection systems ensuring reliable electrical contact and mechanical retention.

Power Distribution

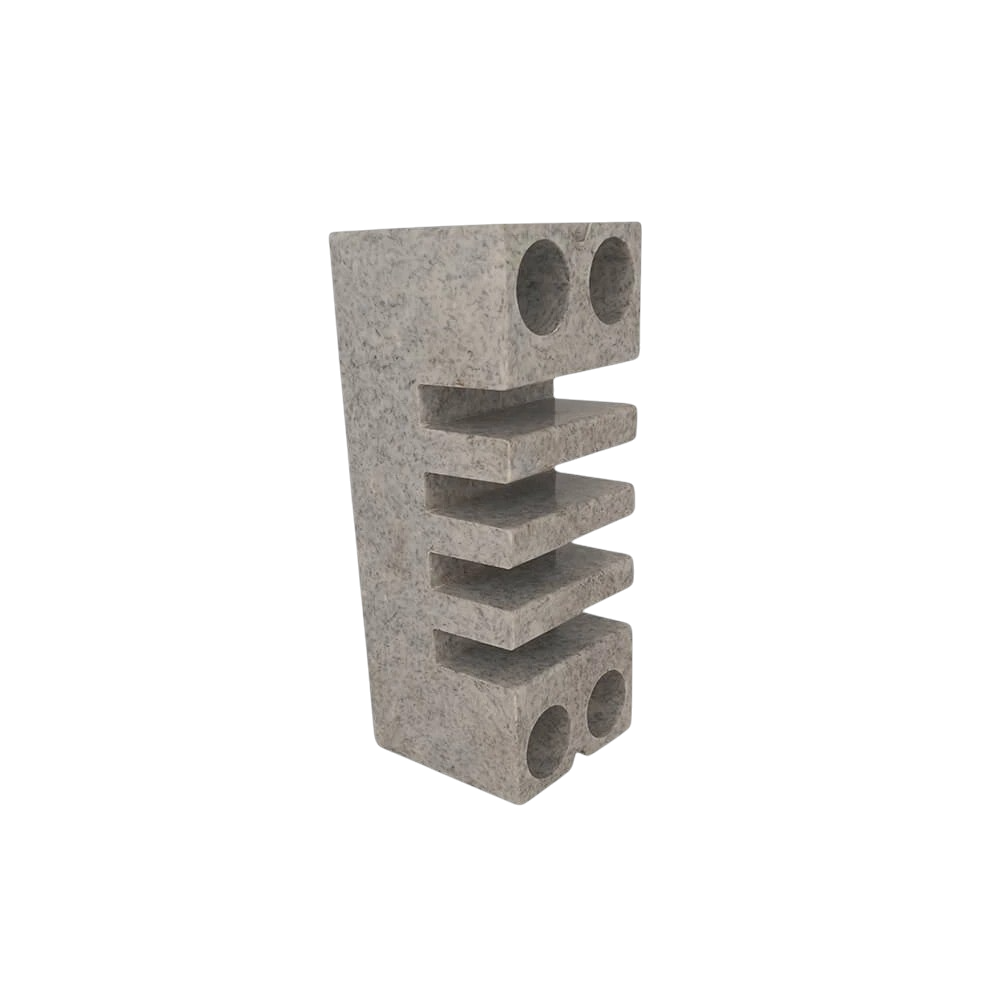

Pin Insulation Components

High dielectric strength insulation parts providing electrical isolation in diverse voltage applications.

Appliances

Terminal Blocks & Strips

Modular terminal connection systems supporting flexible wiring configurations and easy installation.

Control SystemsCore Product & Manufacturing Strengths

Engineering features and manufacturing capabilities delivering consistent quality and performance in electrical components.

Stable Electrical Performance

Consistent insulation resistance and voltage withstand capability through controlled material selection and process validation.

Multiple Material Support

PA, PBT, LCP engineering plastics and UL-certified materials matching specific electrical and thermal requirements.

High Assembly Consistency

Precision molding and tight dimensional control ensures reliable fit and electrical contact across production volumes.

Automation-Ready Design

Components engineered for automated assembly processes reducing customer installation time and labor costs.

Problem-Solving Approach to Customer Challenges

Structured engineering methodology addressing critical technical challenges with proven solutions and measurable improvements.

Unstable Connector Assembly Consistency

Problem:

Electrical connector assembly variations create intermittent contact issues and reliability concerns in field operation.

Solution:

Precision mold fabrication with assembly strategy optimization plus systematic QC inspection at critical process steps.

Result:

Batch consistency improved 30%+ with validated contact resistance measurements confirming reliable electrical performance.

Insulation Failure in High Temperature/Humidity

Problem:

Insulation components experience degraded electrical performance or failure under elevated temperature and humid operating conditions.

Solution:

Material upgrade to moisture-resistant grades combined with insulation design optimization for enhanced creepage and clearance.

Result:

Reliability validation passed critical performance testing including 85°C/85%RH conditioning with maintained electrical properties.

Structured Engineering & Production Process

Systematic workflow ensuring quality control and engineering collaboration throughout development and production lifecycle.

Requirements Review

Technical specifications and application requirements evaluated by engineering team.

Technical Design & DFM

Design optimization for manufacturability and electrical performance validation.

Sample Production

Prototype tooling and initial samples with complete testing for approval.

Volume Manufacturing

Production tooling and process qualification for volume ramp-up.

Full Inspection & Shipping

Complete quality verification and coordinated delivery to customer.

Customer Follow-up

Ongoing technical support and quality monitoring for continuous improvement.

Frequently Asked Questions

What are standard lead times for your products?

Sample development typically requires 2-3 weeks including tooling and testing validation. Production lead time ranges 3-5 weeks depending on volume and complexity after tooling approval. Expedited options available for urgent requirements with advance coordination.

Do you support sample prototyping before production?

Yes, complete prototyping services include soft tooling for rapid sample production, dimensional inspection, electrical testing, and design validation. We provide comprehensive test reports and engineering feedback supporting customer qualification before production tooling investment.

Do you provide UL/3C/CE testing support?

Yes, we work with UL-certified materials and can coordinate third-party certification testing including UL, 3C, CE, and other international standards. Complete documentation packages include material certifications, electrical test data, and dimensional inspection reports supporting customer certification requirements.

How do you handle customer design changes?

Our engineering team provides rapid response to design change requests with DFM evaluation and impact assessment. We maintain flexible tooling strategies allowing modifications during development. For production changes, we follow systematic ECR process ensuring quality validation before implementation.

How do you ensure batch-to-batch consistency?

Statistical Process Control (SPC) monitors critical dimensions and electrical parameters throughout production. First article inspection establishes baseline followed by systematic sampling with automated testing equipment. Process capability studies validate consistency and we maintain comprehensive traceability documentation for quality assurance.