Reinforced BMC & DMC Pin Insulators

Advanced thermoset composite materials delivering superior electrical insulation, mechanical strength, and thermal stability. Direct manufacturer supporting precision engineering for demanding industrial and electrical equipment applications.

- ✓ Enhanced Insulation Performance • Precision Manufacturing • Global Supply

- ✓ BMC/DMC Reinforced Materials • Superior Stability & Performance

Key Challenges in Insulator Component Manufacturing

Pin insulator applications face specific technical challenges requiring advanced materials and precise manufacturing control.

Unstable Electrical Insulation

Standard thermoplastic materials exhibit inconsistent dielectric properties affecting voltage withstand capability and long-term insulation reliability in electrical equipment.

Difficult Batch Consistency

Achieving dimensional accuracy and electrical performance consistency across production volumes requires advanced molding control and material expertise.

Thermal Aging & Mechanical Weakness

Standard plastic materials suffer degradation under elevated temperatures and mechanical stress compromising service life in demanding applications.

Why BMC & DMC Reinforced Materials Excel

Thermoset composite materials engineered specifically for electrical insulation applications where standard plastics fall short.

BMC Advantages

- ✓ Superior electrical insulation with high dielectric strength maintaining performance under voltage stress

- ✓ Excellent dimensional stability and low thermal expansion for precise assembly requirements

- ✓ Enhanced mechanical strength from fiber reinforcement supporting structural load applications

- ✓ Heat resistance to 180°C+ maintaining properties in elevated temperature environments

DMC Advantages

- ✓ Extended service life through superior resistance to thermal aging and environmental degradation

- ✓ Excellent surface finish quality enabling precision molding of complex geometries

- ✓ Low moisture absorption maintaining electrical properties in humid operating conditions

- ✓ Arc resistance and tracking resistance critical for high voltage insulation applications

Complete Engineering & Manufacturing Services

End-to-end support from material selection through volume production ensuring your BMC/DMC components meet specifications.

Material Assessment & Selection

Expert evaluation matches BMC/DMC grades to electrical and mechanical requirements.

Custom Design & Engineering

Collaborative design optimization for moldability, performance, and cost efficiency.

Small Batch to Volume Production

Prototype validation with complete testing before scaling to volume manufacturing.

Rigorous Quality Control

Systematic process monitoring and electrical testing ensures consistent production quality.

Logistics & Global Delivery

Coordinated shipping and inventory management supporting worldwide customer operations.

Engineering Solutions for Critical Challenges

Structured problem-solving methodology addressing specific technical challenges with proven engineering solutions and measurable results.

High Temperature Deformation

Problem:

Standard plastic components deform under elevated operating temperatures compromising dimensional accuracy and electrical safety.

Solution:

DMC reinforced material selection combined with mold flow analysis optimizes fiber orientation and eliminates weak points.

Result:

Thermal stability improved 30%+ with validated performance maintaining dimensional accuracy to 180°C operating temperature.

Production Batch Variation

Problem:

Dimensional inconsistencies across production batches create assembly issues and reduce electrical performance reliability.

Solution:

Precision mold fabrication with in-mold sensors and SPC process control monitors critical parameters during each cycle.

Result:

Production consistency achieved with Cpk >1.67 on critical dimensions ensuring reliable assembly fit and function.

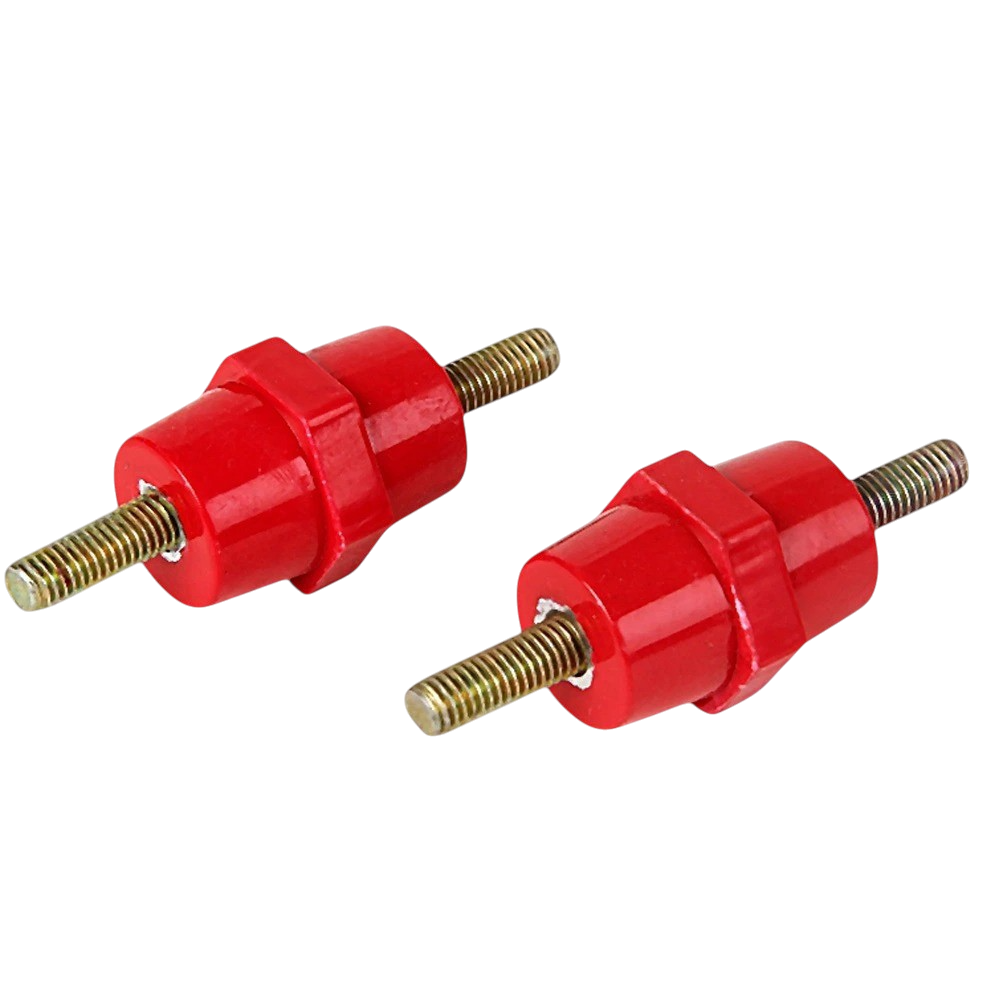

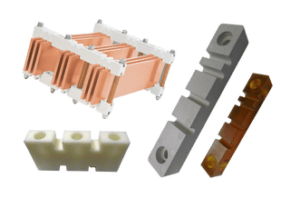

BMC & DMC Pin Insulator Product Series

Comprehensive insulator range engineered for specific electrical applications with optimized material properties and geometries.

BMC Reinforced Pin Insulators

High-strength thermoset insulators with excellent dimensional stability for precision electrical equipment assembly.

Application: Switchgear, Control Panels, Circuit Breakers

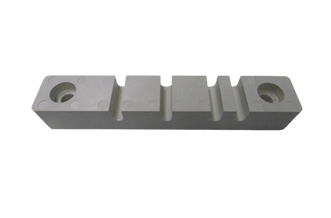

DMC Extended Life Insulators

Superior thermal aging resistance and environmental durability for long-term reliability in demanding conditions.

Application: Outdoor Equipment, High Temperature Environments

High Insulation & Heat Resistant

Enhanced dielectric strength with thermal performance to 200°C for critical high voltage applications.

Application: Power Distribution, Transformers, HV Equipment

Custom Specifications & Assemblies

Engineered-to-order insulators with integrated metal inserts, specialized geometries, and custom electrical ratings.

Application: OEM Equipment, Specialized Industrial Systems

BMC/DMC Performance vs. Standard Materials

Quantified performance advantages demonstrating superior properties of thermoset composites over standard thermoplastics.

Mechanical Strength

40-60% higher tensile and flexural strength supporting structural loads and impact resistance.

Dielectric Performance

Superior voltage withstand with dielectric strength 25-35 kV/mm maintaining insulation integrity.

Thermal Aging Resistance

Minimal property degradation after 1000+ hours at elevated temperature vs. rapid thermoplastic aging.

Extended Service Life

2-3x longer operational lifetime in demanding environments through superior material stability.

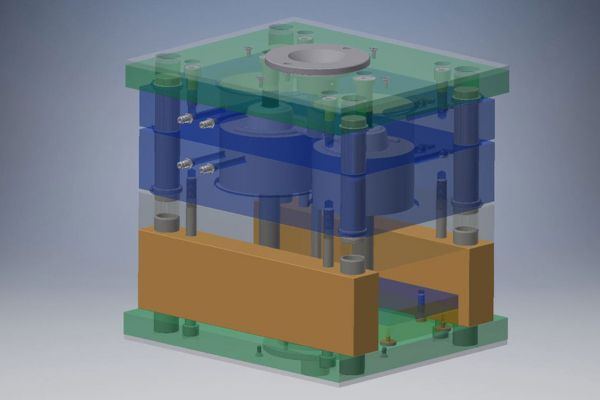

Factory Capabilities & Production Facilities

Specialized manufacturing infrastructure dedicated to precision BMC/DMC molding with complete quality control systems.

High Precision Machining Center

Advanced CNC equipment with temperature-controlled environment ensures precision mold fabrication and component machining to tight tolerances supporting consistent molding quality.

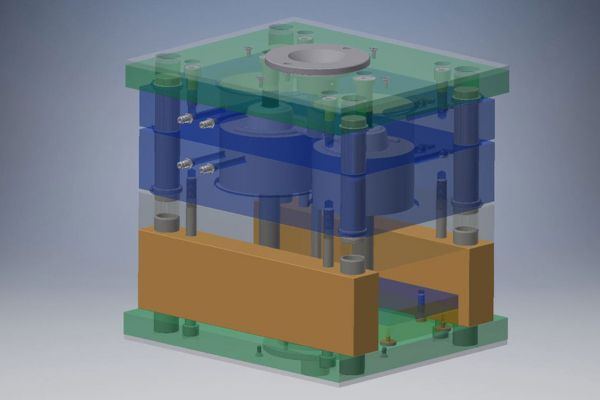

Insulator Material Specialized Molds

Dedicated tooling engineered specifically for BMC/DMC materials with optimized heating systems, venting, and ejection mechanisms ensuring defect-free molding and long tool life.

Engineering Customization Workflow

Structured partnership process ensuring successful development from initial concept through volume production delivery.

Requirements Submission

Technical specifications, application requirements, and target volumes reviewed by engineering team.

Technical Review & DFM

Design for manufacturability analysis with material selection and process optimization recommendations.

Sample Production & Validation

Prototype tooling and initial samples with complete electrical and dimensional testing for approval.

Volume Production

Production tooling fabrication followed by process qualification and volume manufacturing ramp-up.

Delivery & Quality Feedback

Coordinated shipping with complete documentation and ongoing quality monitoring for continuous improvement.

Frequently Asked Questions

What are the key differences between BMC and DMC materials?

BMC (Bulk Molding Compound) offers excellent dimensional stability and mechanical strength ideal for precision components. DMC (Dough Molding Compound) provides superior surface finish and extended thermal aging resistance for long-life applications. Both are thermoset composites significantly outperforming thermoplastics in electrical and thermal properties. Material selection depends on specific electrical requirements, operating temperature, and mechanical loads.

How do you ensure batch-to-batch consistency in production?

Our quality system implements Statistical Process Control monitoring critical molding parameters including temperature, pressure, and cure time. Each production batch undergoes first article inspection with dimensional measurement and electrical testing. In-process sampling with automated testing equipment validates consistency. Process capability studies maintain Cpk >1.67 on critical dimensions ensuring reliable assembly fit across production volumes.

Do you support sample prototyping and testing?

Yes, complete prototyping services include soft tooling for rapid sample production, dimensional inspection, electrical property testing (dielectric strength, insulation resistance), and thermal performance validation. Sample development typically requires 2-3 weeks. We provide comprehensive test reports supporting customer qualification and design validation before production tooling investment.

What are typical lead times for samples and production?

Sample development with soft tooling requires 2-3 weeks including molding and testing. Production tooling fabrication ranges 4-6 weeks depending on complexity. Volume production lead time is typically 3-4 weeks after tooling approval. Expedited options available for urgent programs with advance planning and engineering coordination.

Do you provide quality certifications and test reports?

Complete documentation packages include material certifications, dimensional inspection reports with CMM data, electrical test results (dielectric strength, insulation resistance, tracking index), and thermal aging validation. We support customer-specific requirements including PPAP documentation, third-party testing coordination, and compliance certificates for UL, CE, and international standards.